The ability to inspect a wind turbine without the risk of personal injury is only one of the benefits of the new AutoCopter™ industrial strength, unmanned radio controlled helicopter. We have already demonstrated the benefits of this tool with cell tower and transmission wire inspections, so wind turbines were a natural area of our focus.

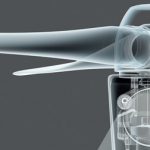

To provide a little background, we began with roof inspections of hail damage, and we then moved to aerial photos and videos of farms. We next worked with cell tower companies, and then with the utility companies. The AutoCopter provides the aerial platform for any type of viewing and recording, for determining present conditions, and/or for documentation of completed repairs and inspections, etc. With over 200,000 turbines in the world—and almost 50,000 in the United States, with the numbers growing—we felt the market was a good one for us to enter. In preparing for this article we found that there is a shortage of climbers, resulting in inspection schedules that are difficult to keep. We believe that our solution will be warmly received. We also found that the industry needs proper training, the need for safer methods to conduct the inspections, and the reduction of danger of the overall inspection process. Figure 1

In terms of their dimensions, AutoCopters are 62” long, 20” tall, and they will fly to the necessary height required for wind turbine inspections. The ability to survey the area from above provides an “eye in the sky” perspective on current conditions or damages. Stabilized software, and AutoPilot software models are available. Features include full auto take-off, waypoint (GPS) tracking, and auto landing. The ability to know the exact location of the camera at any given moment allows for complete documentation while the inspection is in progress.

Our original vision was to be the alternative to the manned helicopter. We have the ability to provide close-up aerial visibility, and to record it without the risk of injury to personnel. The fact that our UAV helicopter costs less than two dollars per hour to fly, will fly all day on a five-gallon can of gasoline, and produce the same visual results as a manned helicopter has been one major reason for our success.

Flexibile Flight

Within five minutes of unloading the AutoCopter it can be at the top of the wind turbine, carefully examining the structure and the blades from any angle. As it flies it is filming in HD video. The ground control station receives live video and is able to see what the helicopter sees as it flies. While this is being done all personnel are safely on the ground, incurring no risk whatsoever. Figure 2

We know that the wind turbine inspection process also requires an internal check of the mechanical and electric heart of the turbine. The AutoCopter can climb to the top in less than 10 seconds, provide aerial shots from above, and methodically view and record from top to bottom. The overall process time is reduced and the results of the inspection are improved because they are recorded in one or two formats: HD video, and infrared/thermal. In addition, the process of observing and recording each turbine blade does not require repositioning the blades after the system has been stopped and turned off. They can be filmed wherever they cease rotation, which helps to reduce downtime. The foundation area directly around the turbine will also be captured on film for immediate analysis.

Maximizing Manpower

We see this “power tool” as an addition to the arsenal of tools and skilled operatives in the wind building and maintenance company’s toolbox. Training takes less than three days, inspection capabilities will be enhanced, your risk of personal injury will be dramatically reduced, and you will be able to allocate staffing ways not possible before. Figure 3

From a simple staffing viewpoint, the operator of the AutoCopter does not need to be a climber or a technician. He or she can be a less costly remote-control helicopter pilot trained for the tasks required. The areas of concern are the flight, recording, video downloads, and creation of the DVD. A recorded history of each wind turbine inspection will be available on the site for future inspections, in the office, and at the client’s location. This would help to expand the limited supply of climbers, thus enhancing the abilities of the inspection team/company. There is also the ability to view and record the condition of bolts, cables, ladders, paint, oil spills, and safety equipment in minutes. Once the exteriors have been viewed, filmed, and analyzed, the AutoCopter crew—both man and machine—can move on to the next location.

We realize it would be illogical to think that the climber could be removed from the equation. We also know our “power tool” would help to expand existing resources, dramatically shortening part of the inspection process and allowing for a different focus for the climbers. Additionally, the cost is reduced and the quality of the inspections has actually been improved because the helicopter uses better optics to view and record what it sees. The additional benefit is that the AutoCopter does not get cold or tired, or need strength and agility to observe the surface. What now takes half a day manually will take only 15 minutes with the AutoCopter, at most. The need for cranes on location might be reduced, and tighter scheduling can be incorporated if the inspections are reduced from weeks to days.

Safe Strategy

Perhaps the most important feature of utilizing the AutoCopter is the ability to keep people on the ground for the entire exterior inspection process. While the helicopter is flying and recording, the images are being sent to the “ground control station” for observation. Skilled technicians can monitor the flight and ask the pilot to go back or to zoom in as it flies. Because the GPS location and altitude are visible on the ground control station as it flies, you can pinpoint the areas needing attention, repair, or just another look. Figure 4

When and if repairs are needed, the team knows the exact location on the turbine. Because it is GPS enabled, it also points to the repair’s exact location on the turbine. The inspection team has looked at it up close while still on the ground and knows exactly what tools and materials are needed before they climb the tower. The ability to reduce the number of climbs would have a beneficial effect on personnel and safety.

The need for inspection often conflicts with tightening budgets and the resistance to taking the unit out of service. When taking pictures from the ground you’re looking up, which can’t provide the same view as if you were at eye level. How would you get pictures from above as part of the routine inspection before the AutoCopter? Slight leaks might be visible in the air but not from a ground camera, because of the angle or location.

Increased Efficiency

For the turbine to maintain the maximum output, the blades need to be inspected and maintained regularly. If blade maintenance is a critical factor and would benefit from more frequent inspection schedules, there is now the possibility to send someone to inspect, armed with this new power tool and record conditions.

With the growing number of wind turbines operating out of warranty this poses additional worry, because they must be serviced more frequently. It would not be too costly to send man and machine for a quick check after lightning or hail storms, for example. And since time equals money, the following scenario detailing the inspection of 45 turbines might be useful to consider:

Plan A

• Inspection and shutdown on August 1 forward;

• Inspect the wind turbines, typically two per day;

• Projected total time for inspections is 22-plus days (min.);

• As external damages are discovered, they would be repaired;

• If internal repairs would be needed, they would be repaired;

• Timeframe of total group inspection varies as requirements dictate.

Plan B

• Planned inspection and shutdown on August 1

forward;

• Inspect all units first with the AutoCopter’

• By August 3, all exterior inspections are complete;

• In less than two days (plan for 10-12 minutes per turbine inspection) all turbines are inspected;

• The results have been recorded, documented, and archived on DVD;

• Images of damages found can be forwarded to the home office for repair provisions, if not available in the field;

• While the internal inspections still remain, all exterior inspections are completed and any repairs needed can be started;

• The knowledge of the condition of the exteriors of the towers and blades before the end of the second day will enhance planning and staffing.

So, in less than three days 45 turbines have been inspected. If the results are that six of the 45 have exterior damage and are in need of repair, and four have items to watch but do not represent an immediate need, the time spent in the field is reduced. Therefore, if you take Plan B into consideration you would inspect four per hour, with the inspection of 28 per day (seven hours of inspection), resulting in 140 per week. Assuming bad weather and other variables, one man travels to sites for 120 working days per year. With a total of 3,360 wind turbines inspected, if you assume a cost of $400 per day—$200 pay plus $200 expenses—the cost for all 120 days is $48,000, and the cost per turbine inspection is under $15.00. We believe this is a number that deserves some attention.

Infrared Recording

Our work using an HD video and the infrared/thermal camera with a fire department in Europe expanded our capabilities to add this inspection tool to the aerial platform. The structure flaws result in temperature variations and are shown on film. A complete infrared/thermal recording can be done while the HD video is recording. This does not extend the time of flight because both cameras are recording at the same time. Maintenance and repair schedules can be amended after such a thorough inspection, helping to prioritize maintenance and reduce repairs. Figure 5

Last Call

When a turbine is constructed the need to evaluate the condition before it is turned over might be helped by the aerial inspection of the AutoCopter. A physical and infrared/thermal evaluation while the contractor is watching the ground control station might help confirm questions, issues, and mutual agreements.

When a turbine warranty is about to expire, the “last call” for issues both visible and hidden is important for the cash flow future of the turbine. The ability to predict and prevent costs is important. How much better is it to be able to illustrate on film the issues requiring attention and/or repair? Because the film is recorded to DVD there is a written, embedded date and time stamp that meets the best evidence rule as a legal document, all the way up to the Supreme Court. If you had an Infrared benchmark record and you provided an end of warranty record, how do you think your complaint might be received? It also eliminates the process of handwritten notes and visual inspections with geo-referenced, recorded video that captures critical information meeting annual inspection requirements.

Based in Charlotte, North Carolina, the AutoCopter Corp. help solve problems on four continents in various applications: cell tower inspection, real estate, agriculture, industrial inspections, firefighting, search and rescue, observation and surveillance. The company’s products are easy to use, designed for use in the field, and ready to use when shipped. Just uncrate, add gasoline, and you’re on top of the wind turbine in seconds.