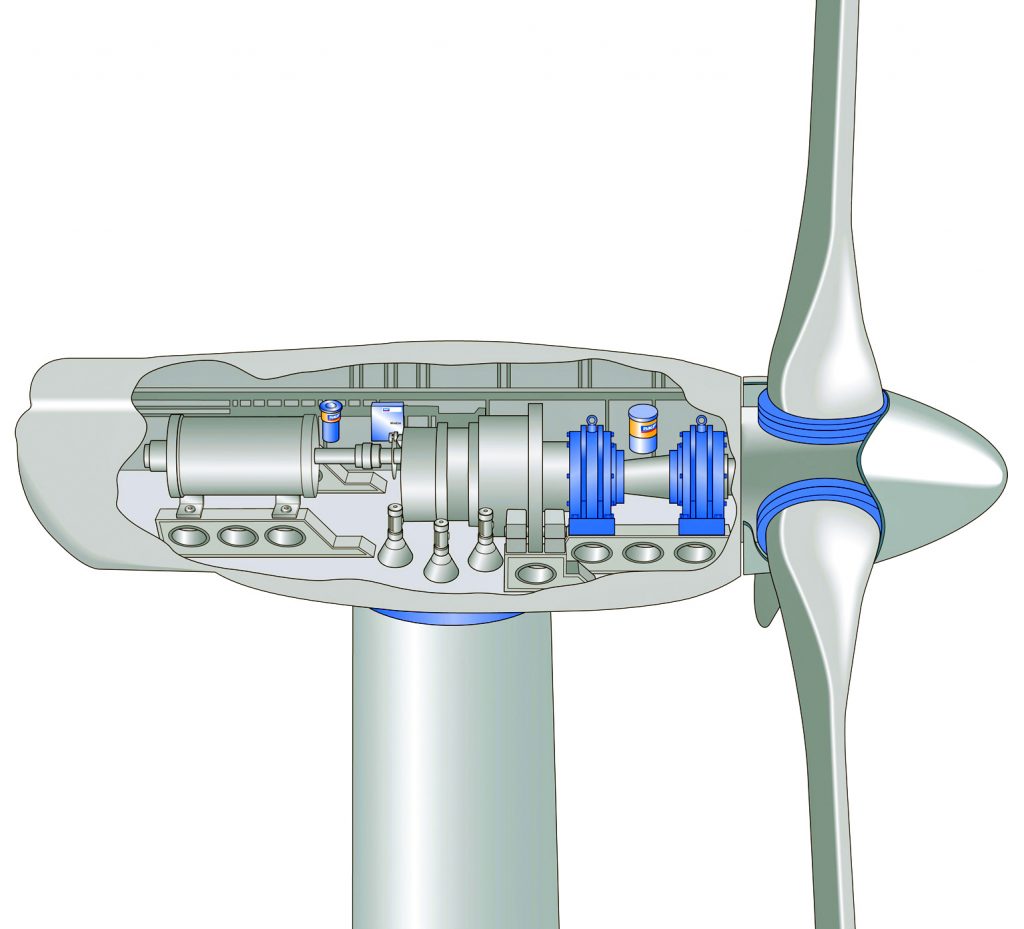

Wind turbines are typically designed to support a 20-year life cycle. Components are often subjected to extreme operating and climate conditions that can affect reliability, productivity, and, ultimately, service life. However, when properly maintained, they can continue to operate well beyond their expected lifespan.

Operators are continually looking for new ways to help extend the service life of bearings in wind turbines. This article explores how technicians can prolong rotating equipment life in wind-turbine operations through proper bearings selection and installation, appropriate maintenance practices, condition monitoring, and predictive maintenance.

Specification to Improve Bearings Service Life

One of the best ways to extend the life cycle of a wind turbine is by ensuring the correct bearings are specified and installed for every application. Each bearing has a unique set of design features and characteristics that often cannot be detected simply by looking or even handling the bearings.

The conditions in wind turbines require special bearing features and specifications that generate different and special part numbers. Many bearings are designed specifically for the wind industry.

Components in turbines undergo thorough testing before being placed in operation, but parts have historically been evaluated individually instead of evaluated according to how they work with other components in a system. This approach is changing with more comprehensive testing involving all interacting components, and with the use of advanced simulation of conditions to mirror real-world applications. This should go a long way in extending the lifespan of wind turbines.

Over time, the final product designation is often changed through several design and testing iterations. Referring to the product designation marked on each side of the bearing is a good start. Technicians are best suited to consult a bearings engineer to confirm an accurate product selection.

Getting the Right Assembly

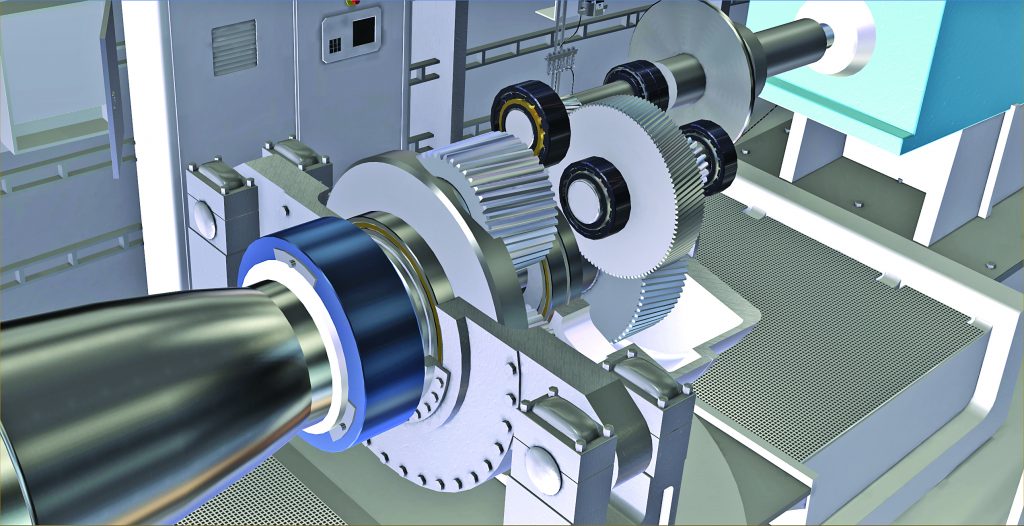

Once the bearing is selected, correct installation in each application is also important — particularly bearings installed in the gearbox to achieve the right preload. To save on initial costs, OEMs may guide operators to buy single bearings and then machine the spacer themselves. This can pose a challenge since bearings are made with a certain tolerance range that can affect the desired preload.

One important consideration for bearings in the gearbox is to ensure they have optimum clearance since preloading generates additional heat and friction. Ideally, bearing replacements should be made in the workshop so technicians can measure and dial-in each component and gauge. Servicing wind turbines makes up-tower repair a necessity where space is at a premium. Bearings experts can help define acceptable tolerances and identify steps to be completed in a workshop so technicians can carry less equipment and save time for up-tower repair — while still achieving the desired outcome.

Reducing Premature Bearings Failures

The reliability of equipment is an ongoing concern for wind-farm operators — and the dependability of bearings at all points in a wind turbine is a critical part of the mix. Fatigue of bearings may be caused by higher-than-expected stresses driven by a variety of factors, including heavy moment loads, friction, and heat. It may also be caused by diminished material strength due to environmental factors, including water contamination and corrosion, as well as stray electrical currents. There are several ways to help mitigate the risk of early bearing failure.

To prevent the early onset of cracks due to potential chemical attack on steel bearings, SKF recommends using special surface treatments like black oxide. When applied to bearings rings and rollers, black oxide coating has also been shown to reduce other damage mechanisms, such as corrosion, smearing, and adhesive wear.

Proper lubrication management and regular maintenance can help prevent surface distress, like micropitting and smearing damages. Correct sealing design to maintain appropriate levels of available lubricant help to mitigate lubrication starvation.

Another example is electrical damage in wind-turbine generators, which is the cause of 70 to 80 percent of bearings failure. Depending on the conditions, there are a variety of insulation methods to reinforce the bearing’s performance. These include specialized protective surface treatments and coatings such as aluminum oxide INSOCOAT® coated bearings and hybrid bearings integrating extremely hard and durable ceramic rolling elements.

Advancing Standard Lubrication Practices

Like any mechanical system, wind turbines need proper lubrication to function optimally. Studies have shown that 36 percent of premature bearing damage is due to improper lubrication. Used grease can harden up in the bearing. Fresh grease pumped in is competing for space with this hardened grease. The new grease might find an easier way out of the bearing instead. There are several methods to remove this used grease and replenish with fresh grease. A properly designed and executed lubrication program helps prevent lubrication-related damage and supports optimum bearings performance and service life. Vibration, high mechanical loads, contamination, and moisture are all threats to lubricant life in bearings and gears. High temperatures and speeds inside the generator require specially formulated lubricants and an efficient automatic lubrication system.

There are some common misconceptions when it comes to proper lubrication practices — particularly as it relates to both quantity and frequency. Over-greasing or under-greasing, sporadic or ill-timed lubrication intervals, as well as the risk of introducing contaminants, makes manual lubrication less desirable. Up-tower lubrication points may be difficult to reach or inaccessible — further contributing to manual lubrication being more challenging and dangerous.

Automatic lubrication systems can provide a quick return on investment by increasing turbine system availability, extending maintenance intervals, and service life of major components. Additional savings can be achieved through proper lubricant handling and consumption.

A Safer, Smarter Solution for Inspections

Technicians often ask how to predict the remaining life of a bearing during routine manual inspections, as well as what wear characteristics to look for in components surrounding the bearing. There is a range of issues to look for in bearings, including pitting, denting, false brinelling, and thermal cracking. However, these characteristics are not always visible without specialized equipment. Due to the equipment required and lack of access, regularly scheduled manual inspections do not always provide an accurate assessment of bearing health.

Having the ability to collect vibration reports and temperature readings through condition monitoring helps identify the onset of bearing damage. Enabling operators to monitor and track deteriorating component conditions in real time allows maintenance decisions to be made based on actual machine conditions, rather than arbitrary inspection schedules. This may also permit maintenance intervals to be extended while consolidating risky, costly, manual activities.

Monitoring Assets to Prevent Failures

As much as possible, bearing replacements are done up-tower. Large bearing replacements cannot be done up-tower and require a workshop. Workshop repairs for wind turbines can be as much as $250,000. Maximizing productivity involves more than just conducting routine maintenance — it requires using condition monitoring tools, such as smart sensors connected to the cloud, to help service technicians predict equipment issues promptly before they require up-tower or workshop repair.

Advancements in condition monitoring allow companies to track bearing vibrations, temperature, and other data to establish baselines. Operators can also collectively monitor all the turbines on a wind farm and establish trend analyses to make future predictive maintenance decisions.

Having the ability to cross-functionally compare factors such as vibration, temperature, and oil analysis allows operators to get an overall snapshot of machine health. These analytics can deliver actionable information for quick and strategic decision-making. Connecting, collecting, and correlating data provides a new way for people to interface with machines to increase efficiency and productivity.

The Value of Predictive Maintenance

Optimizing machine uptime is key to increasing energy output while reducing life-cycle costs. Predictive maintenance (PdM) is a strategic approach to monitoring machine health by using connected devices to collect data on a variety of assets. Data is then aggregated and analyzed to deliver valuable, actionable insights.

Implementing a PdM program with condition monitoring enables the detection of faults before they progress to failure. The result is optimized bearing service life over the long term, more turbine uptime, and reduced man-power costs — all combining to help make wind farms more profitable. Optimizing the existing bearings selection and installation, maintenance practices, and condition monitoring can help unlock the value of predictive maintenance to a wind farm.