That also applies to gearboxes in windpower turbines functioning as the main constituent of the drive train. Journal bearings now offer a technology that is already being used successfully in other areas of industry and is further enhancing the availability of windpower systems.

Experience shows that journal bearings make a very good alternative to the roller bearings so far used in windpower gearboxes. The area of application for journal bearings is very varied: for large, heavy-duty applications hydrodynamic journal bearings in particular are worth considering. In the past such applications have been mainly large industrial gear units for driving mills and ships. In these applications journal bearings stand out for their high reliability. Because of this experience journal bearings are also a highly promising alternative for use in the drive systems of windpower systems, particularly in gearboxes.

The development and design of bearings in windpower gearboxes represent an increasing challenge as gearboxes get larger and their load and deformation conditions change accordingly. Positive experience made with journal bearings in industrial applications can be used to good effect in the windpower sector, if windpower-specific limiting conditions are taken into consideration. The high loads at low sliding velocities are a particular example here.

For the use of journal bearings in windpower-specific applications special operating conditions must be taken into consideration. Such conditions include low-temperature operation, the idling condition, emergency stops and all part-load operating conditions.

Tests On Journal-Bearing Test Rigs

To validate their suitability for operation in windpower gearboxes, Winergy subjected journal bearings to exhaustive tests. To estimate the limits to the loads on and use of journal bearings in windpower gearboxes, tests can first be conducted on bearing test rigs. For this, a test rig of the kind shown in Figure 1 was built. This test rig has a bearing holder to receive a radial journal bearing with a nominal diameter of 120 mm. This is roughly equivalent to the bearing size of a two-megawatt windpower gearbox on the high-speed generator shaft (HSS).

The test rig is fitted with a friction balance to enable the friction torque in the journal bearing to be directly measured.

Various metallic bearing materials were tested under windpower-specific conditions. High torques occur, particularly when braking a turbine, until the system comes to a standstill. These emergency stop tests were repeated 2 000 times without measurable wear being found. Only run-in wear of the order of magnitude of < 1 µm was visible.

The Stribeck curves on Figure 2 clearly show that the level of friction after run-in is below that of roller bearings. At the same time the friction minimum at very low sliding velocities is less than 0.2 m/sec. Since rated operating velocities are considerably higher, hydrodynamic operation is possible in the rotor side of the gearbox.

Tests On Gearbox Test Rigs

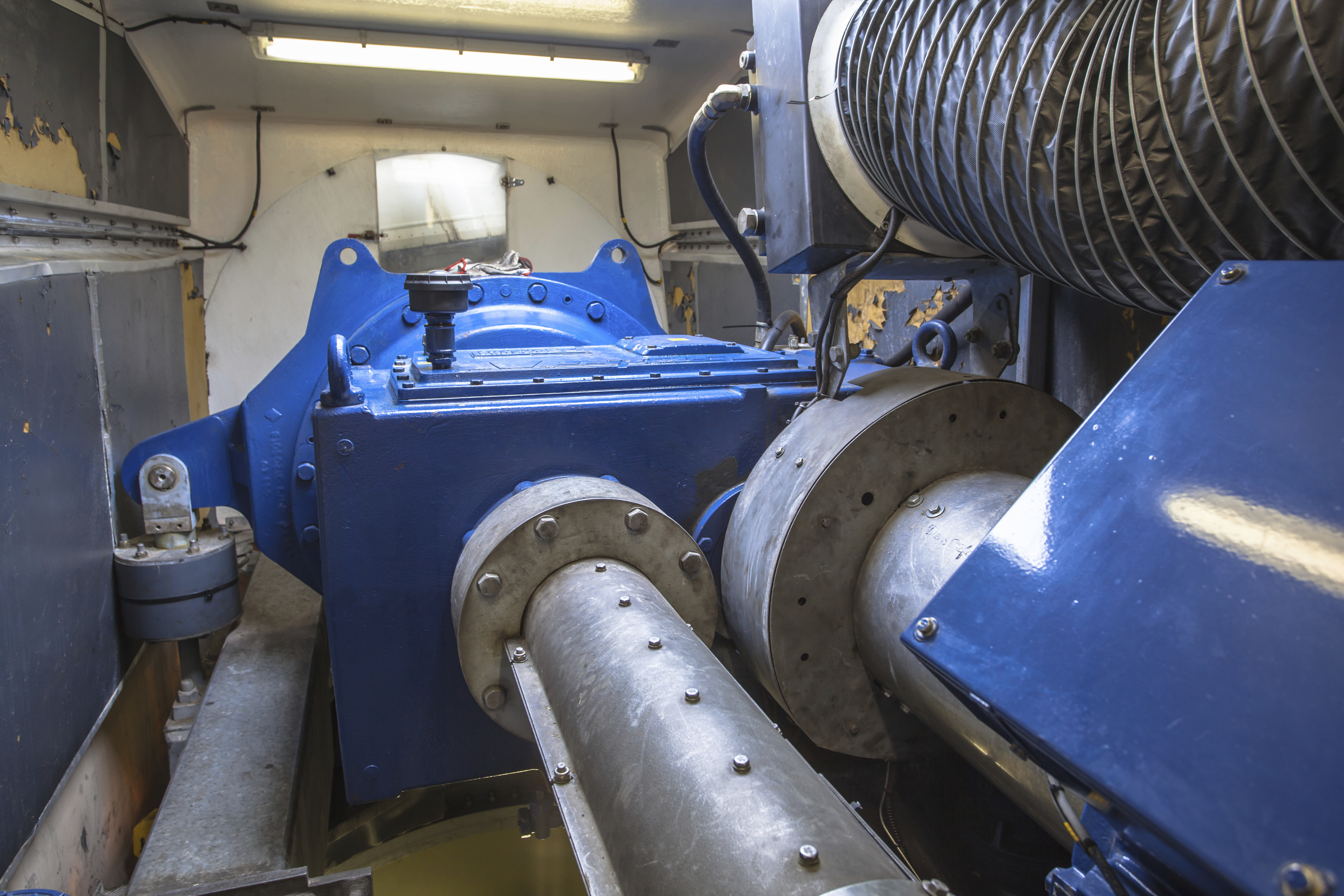

Further validation of the use of journal bearings in windpower gearboxes is based on a two megawatt gearbox fitted with roller bearings in series. The aim here was to use the space required for roller bearings for the use of journal bearings. The gear used was a three-stage planetary cylindrical-gearbox comprising a planetary stage on the rotor side and two cylindrical gear stages to follow. The planetary stage was driven via the planetary carrier, while output was via the central sun pinion with a fixed hollow gear. This gearbox was fitted entirely with journal bearings. The only exception was carrier bearings 256 and 255, as shown on Figure 3.

The gearbox was subjected to various tests on the test rig. Tests were conducted with part, nominal and overload, in idle operation under cold weather conditions, as well as various special tests. Figure 4 shows a complete overview of the tests conducted.

The tests were conducted sequentially on the same gearbox. On completion of the tests the bearings were inspected and measured. The journal bearings were found to be in a faultfree condition – no damage had occurred. Subsequent 3D measurement of the journal bearings showed that the bearings had not undergone any deformation and so no wear occurred.

The test rig tests also showed that the power losses on the gearbox variant fitted with journal bearings were no higher than those on the variant with roller bearings. In the low-speed range of the gearbox lower power losses occur on the low-speed shaft (LSS), whereas in the high-speed range slightly higher power losses of the journal bearings occur on the HSS. No increase in the cooling capacity of the gearbox or in the volumetric oil flow is necessary.

A 10-day idle test under cold conditions was conducted at – 40°C. Here too no abnormalities occurred. The emergency running properties of the material used for the bearings are adequate for such conditions.

As expected, structure-borne sound vibration was reduced in comparison with the roller-bearing variant because of the excellent damping properties of the journal bearings at all gearbox stages.

Prototype Field Validation

After successfully passing the tests on the test rig, the gearbox was installed in a Vestas V90 series turbine; it has been running faultlessly for two years; behaving in the turbine the same way as it does on the test rig. The good noise characteristics were confirmed, and the oil analyses conducted during running time show no impurities from wear.

This behavior too can be assessed by monitoring the temperature of the journal bearings. Figure 5, for example, shows the daily records of temperature measurements. These show clearly the link between current operating condition and the corresponding temperature level.

The nominal load condition is marked by an even operating temperature of the journal bearings. The different part-load conditions under constantly changing wind conditions express themselves in changing temperatures.

Summary and Conclusions

As previously mentioned, application-specific investigations have shown the use of journal bearings in windpower gearboxes offers a very good alternative to roller bearings. The advantages that journal bearings already show in other applications also show clearly in the windpower sector.

Test-rig tests have confirmed journal bearings can be operated hydrodynamically in windpower gearboxes without causing wear. This finding is supported by the successful field operation of the prototype fitted with journal bearings that has been faultlessly in operation for two years now. Journal bearings also behave very well during operation in windpower-specific conditions. Also special operating conditions like prolonged idling and emergency braking are borne by journal bearings without any problem. It was also found that windpower gearboxes fitted with journal bearings show low sound radiation because of the greater damping capacity of hydrodynamic journal bearings. Since journal bearings take up less fitting space, gearboxes fitted with journal bearings can also be built more compactly and more cost-effectively.