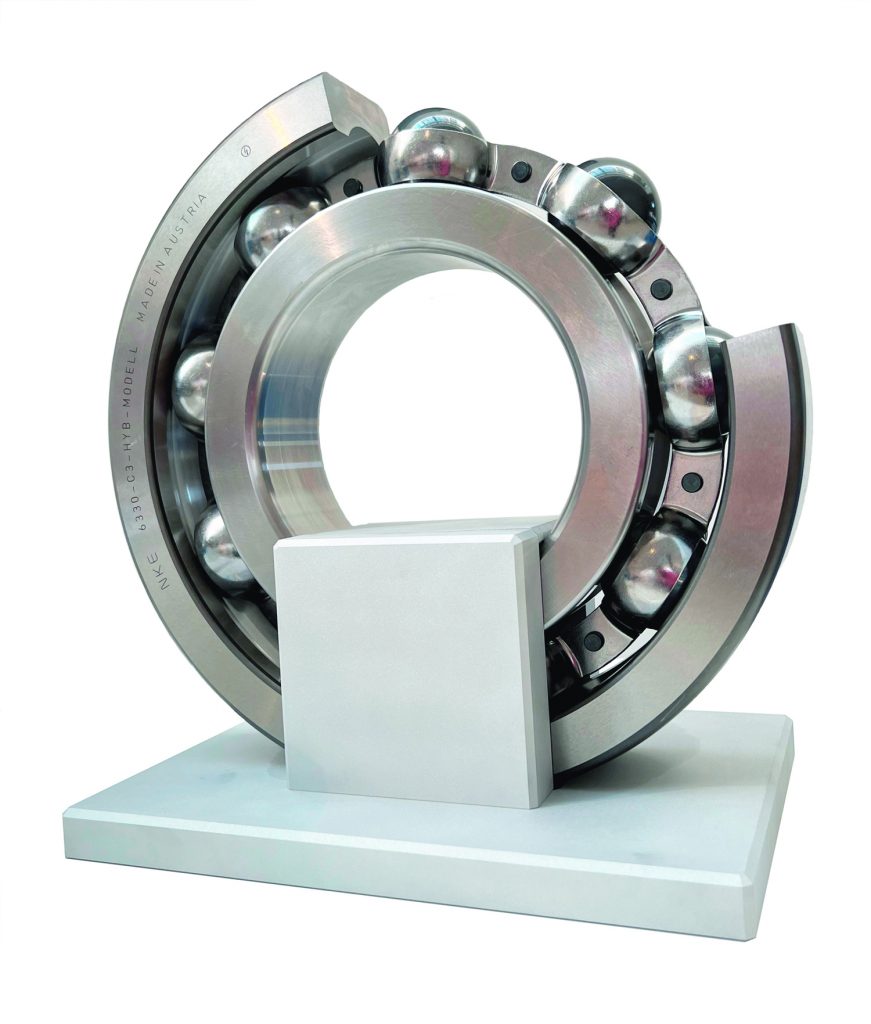

Bearings might not be the first thing thought of when looking at a wind turbine, but they are essential parts that allow it to not only generate power, but produce it as efficiently as possible.

Bearings are used in many areas of turbines, and NKE Bearings has been manufacturing those crucial turbine bearings as well as offering solutions to increase the life of existing bearings for more than two decades.

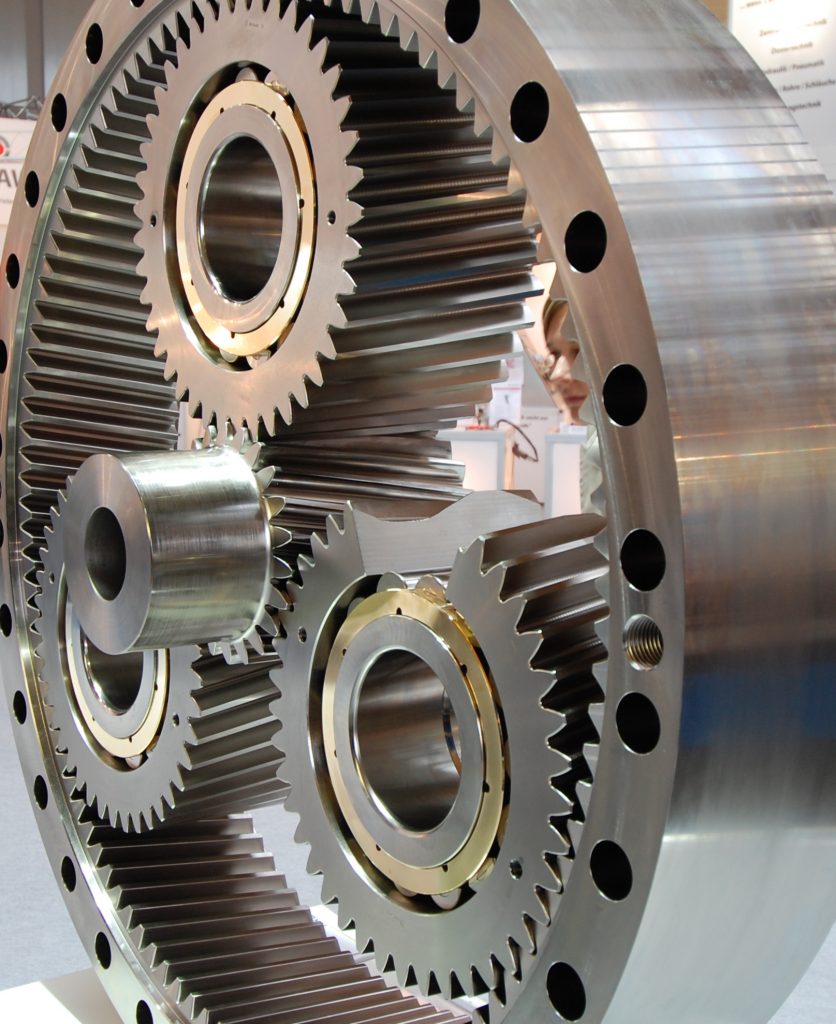

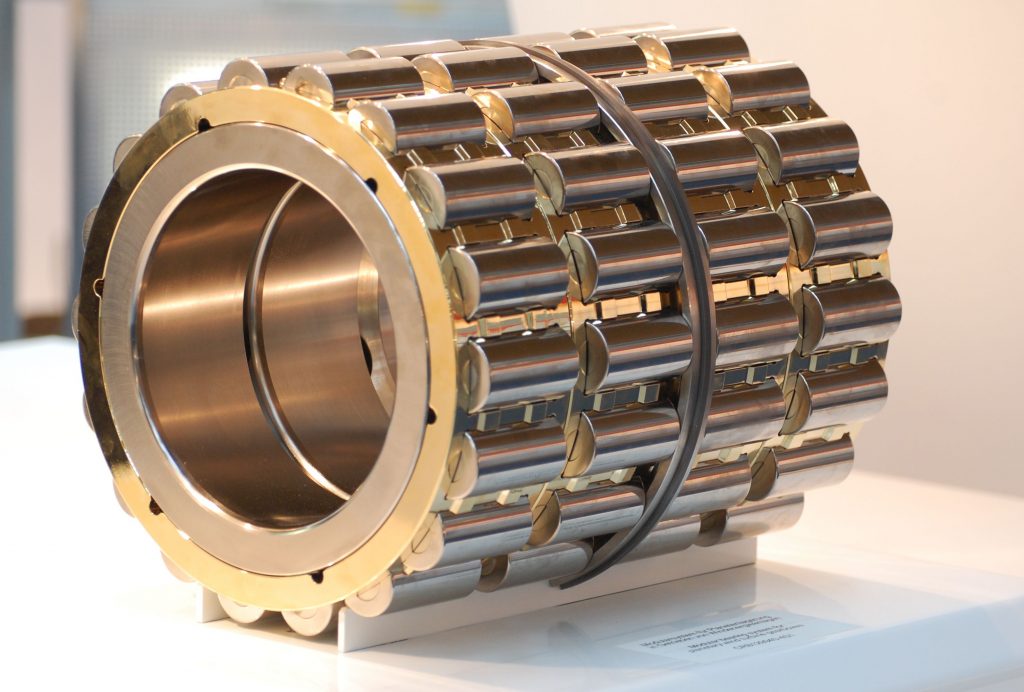

“Globally, we provide bearings and bearing solutions in the gearboxes, the pitch motors, the generators, and the main shaft bearings,” said Dan Karns, deputy general manager of NKE Bearings North America. “For both OEM and AFM, we supply bearings for the gearboxes and generators.”

Bearings for Various Industries

Although NKE has been working with the wind-energy industry for nearly 20 years, the company has been making bearings for various industries for more than 30 years, including rail, slurry pumps, and mining, according to Karns. But it was the company’s expertise with gearboxes and electric motors that led it to wind.

“We shifted focus as a bearing manufacturing company ‘for everything’ to more specific applications, and we identified that we were really strong in gearboxes in general,” he said. “We have always been active and strong in rail and industrial gearboxes, so we thought we’d be a natural evolution to the wind sector. We just leveraged that, and it was the same with electric motors.

We have some insulated products that are just top-notch using both silicon nitrate and aluminum oxide, used to insulate rings or coat bearings on the ceramic balls. We’ve been able to leverage that in the wind sector specifically to really grow the business.”

As NKE’s experience with providing bearings for turbines increased, the company began to branch out into the commodity side of the industry to become more solutions oriented, according to Karns.

“Our black oxide coating and other coating solutions increase the bearing life in turbine gearboxes,” he said. “We insulate pieces in the generators, and we offer high-temperature solutions in the pitch motor and on the service side to increase the life of the asset, providing some added value you don’t necessarily get on the OE side.”

Service Side of the Company

Offering expertise on the service side of the business allows NKE to work closely with its customers in order to find solutions to a wide range of challenges, according to Karns.

“We sit down and work together with our customers to identify how we will deal with issues of operating conditions in the pitch motors as they’re re-manufacturing those motors — then we come up with a solution,” he said. “Our partnership with our customers is a big differentiator, particularly in the aftermarket, where many folks don’t necessarily have access to engineering. Our applications engineers are heavily involved to make sure we’re solving problems and anticipating their future needs.”

Those steps have become an essential part of NKE’s aftermarket regimen, according to Karns.“That’s part of our service strategy in the aftermarket — to work with the people who are doing the repair work and be as close to the customer as possible,” he said. “We work on those things together. It’s a very collaborative process, and we’ve seen tremendous growth globally because of that switch. We have made an intentional move away from just being a bearing manufacturer in the commodity market. Now we bring added value by helping to solve problems and alleviate pain points.”

‘Pushing the Envelope’

Karns believes the close relationship NKE has formed with its customers in order to take care of ongoing problems has become a major portion of the company’s expertise, while also investing heavily in technology and supporting green initiatives.

“We are always pushing the envelope on various initiatives on our R&D side, and so, we’re always trying to look at the ‘what’s next?’” he said. “We’re looking at sensoring and coatings, and what we can do to help streamline that and add value. Can we do some additional tooling that will help on the installation piece, for example? There’s just a myriad of things that we do to support our customers’ needs. We truly look at partnerships when we’re working with our customers. We are moving beyond the idea of a bearing as a commodity.”

Compared to other industries such as oil and gas, wind energy is still relatively young and learning how best to establish itself in the global energy landscape, according to Karns. But that youthful advantage often leads to bursts of development.

“If you look at a parallel to oil in the 1920s, we’re not thinking of oil today, which has 120 years behind it,” he said. “With wind, we still have a long way to go, but that allows for innovation to happen. Smaller wind turbines are starting to come to the end of their life cycle, so how do you support the bigger turbines? What lessons have we learned on the smaller turbines that can apply to the larger turbines? It’s the same when looking at onshore vs. offshore.”

Austrian Roots

The origin of the company can be found from the famous “Steyr Wälzlager” (translated: Steyr Bearings), according to Karns. This company was acquired by SKF in 1989. The leadership, who had a wealth of bearing knowledge, decided in the mid-1990s to leave and start its own bearings manufacturing company, which became NKE. The company supported wind, rail, mining, and other industrial applications offering up to 10,000-part numbers.

However, six years later, building on its core competencies, NKE placed a strategic focus into wind (and rail). This shift has allowed the company to compete with the larger bearing manufacturers.

“We have experienced record turnover this past year as we have made our shift in our philosophy, and the company has continued to just explode with growth,” he said. “It’s pretty cool to know you’re making an impact on a couple of different fronts: We are helping the environment because we’re helping reduce the carbon footprint, and we are helping diversify our energy streams and our energy needs.”

And this applies particularly to wind, according to Karns.

“Wind is a big player in that,” he said. “And because we’re growing, we’re adding lines. And that’s creating more jobs and opportunities for people. Anything we can do to grow the economy and put people to work, whether it’s back in Austria where we manufacture or it’s here in the U.S. by adding engineers, sales folks, and warehouse personnel, those are all net positives.”

Some of that growth has been offshore jobs in Europe, but in the U.S., Karns said numerous onshore projects are keeping the company busy.

Continued Growth

Even though NKE’s schedule continues to be full, Karns said there is only more advancement to look forward to in the wind sector as it continues to grow and mature as an industry.

“I think there’s still vast growth and opportunity and massive learning that’s happening, so I think innovation will continue to move quickly,” he said. “Officials have enacted some of the government legislation that provides a steady runway to help support that growth. I know there’s controversy about whether this should be a government subsidy or not, but I think the reality is energy is subsidized. You look at oil and gas, and it is completely subsidized. It’s just a function of: ‘You’ve got to have energy.’”

That will only allow for NKE’s portfolio to become more robust, according to Karns.

“Just from an operational perspective going forward, I see us being involved more in the main shaft bearings; I think that’s just the next evolution for us,” he said. “And we’ll continue to help our customers solve problems. What we do well — and actually I think we do it probably better than many other bearing manufacturers — is that we are very agile and can move very quickly through the validation process. If there’s a challenge with a customer and they’ve got a pain point and they want to do something, we can design it, field test it, validate it, produce it, and do it quickly. Sometimes it takes larger companies upwards of two years to do something like that. We can do that in six to nine months.”

That’s the ideal arrangement, according to Karns, for customers with a business model that can’t afford to idly sit.

“If we can help keep their turbines turning and we can provide those solutions, then we’ll do that,” he said.

More info www.nke.at/en