The rising concerns over climate change, environmental pollution, and energy security have increased interest in developing renewable energy. We are seeing an unparalleled enthusiasm, demand, and growth in renewable energy production, wind energy being at the forefront. Wind energy is expanding both onshore and offshore with bigger, more powerful turbines, creating new demands and markets.

The global capacity for generating power from wind energy has grown continuously since 2001, reaching 591 GW in 2018 (9-percent growth compared to 2017), according to the Global Wind Energy Council [1].

Wind-Physics Fundamentals

Wind arises from processes driven by solar energy. The sun’s energy creates temperature differences that drive air circulation. Hot air rises, reducing the local atmospheric pressure; nearby cooler air flows into this region of lower pressure; this air flow is wind.

Wind is shaped by both global and local forces. Global patterns are in part the result of the Coriolis force, which arises from the Earth’s rotation. As cool air flows from higher to lower pressure areas, it is deflected by the Coriolis force; the direction of deflection depends on latitude. As a result, different regions of Earth have different prevailing wind directions.

At the other end of the spectrum, local geographical features can have specific effects. One such effect, familiar to anyone living near the ocean, is the land breeze. At night, the water is warm relative to the land, so air is warmed over the water and rises; the resulting low pressure draws cool air from land out to sea: the land breeze.

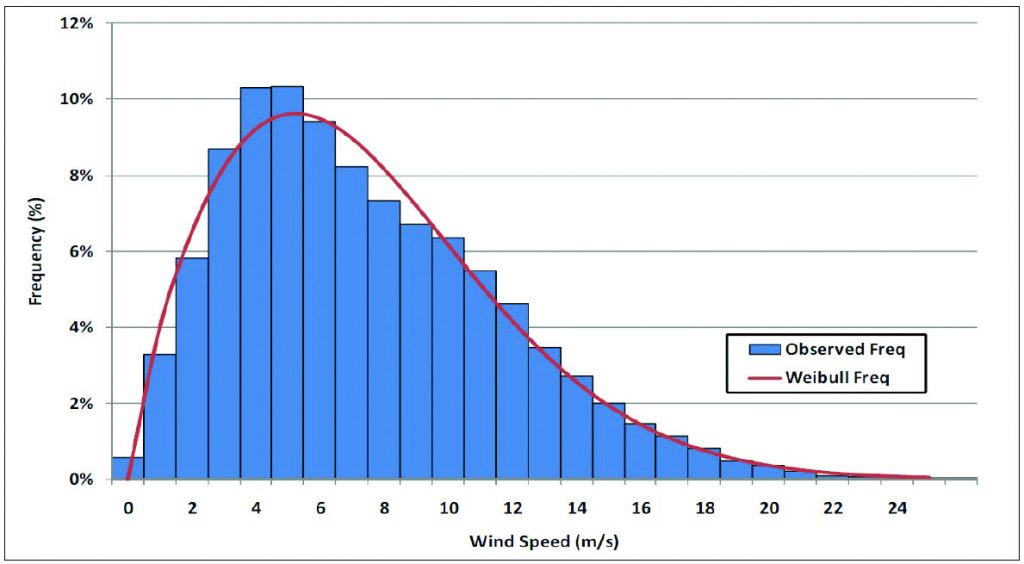

Although there may be a prevailing wind direction, it is not the only wind direction. Both direction and speed are highly variable with geographical location, season, height above the surface, and time of day. Understanding this variability is key to siting wind-power generation, because higher wind speeds mean higher duty cycles (i.e., longer periods of active power generation). It is necessary to measure the characteristics of the wind in great detail, including how often winds of certain speeds occur (see Figure 1) and how the surrounding terrain affects the stability of air flow.

A stable flow with a consistent speed is important for both generating efficiency and structural integrity. Variability leads to wind shear and wake forces. Wind shear is a function of wind speed, which increases with height above the surface. Thus, the shear forces on the rotor blade are greater when it is in the top position.

Equations for Wind Turbines: Wind Shear

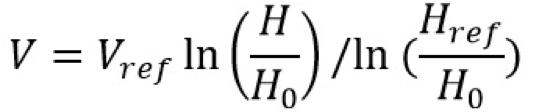

An important consideration for turbine siting and operation is wind shear when the blade is at the top position. Wind shear is calculated as:

V — Wind speed at height H above ground level.

Vref — Reference speed.

Href — Reference height.

H — Height above ground level for the desired velocity, V.

H0 — Roughness length in the current wind direction.

Equations for Wind Turbines: Turbine Power

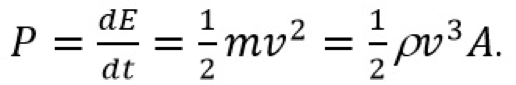

The energy contained in a mass, m, of moving air with velocity v is:

![]()

The mass flow rate of moving air with a density ρ through a cross-section area A is:

![]()

The power contained in a flowing mass of air through area A is:

The power extracted by blades of diameter d is:

![]()

where the power coefficient cp has a theoretical limit of approximately 0.6; this is referred to as the Betz limit, which defines the maximum amount of wind kinetic energy that can be converted to kinetic energy.

Wake forces are created because the wind slows down and becomes turbulent as it passes the turbine blades. This is why turbines are widely spaced, usually five to nine rotor diameters in the direction of the prevailing wind and three to five rotor diameters in the perpendicular direction.

Wind speed also changes as a result of turbulence, which can be caused by nearby rough terrain, including trees and buildings; these can cause wind speed to vary greatly even within several hundred yards or meters. This effect, called turbulence, decreases efficiency and causes fatigue loading.

Wind Power Fundamentals

Energy is captured from wind through the phenomenon of lift — the same phenomenon that allows birds and airplanes to fly. (Turbine blades are, in essence, captive wings.) The lift generated as wind passes over the blade causes it to move, thereby rotating the main shaft. The rotation is transmitted through a gearbox to a generator, which converts it into electricity. The magnitudes of the lift and drag on the turbine blade are dependent on the angle of attack between the apparent wind direction and the chord line of the blade.

Several different factors influence the power output of a wind turbine. Among other factors, wind speed and rotor diameter are the two primary parameters (see Equations for wind turbines).

Turbine power increases with the square of blade length. For example, increasing the rotor diameter from 262 feet (80 meters) to 394 feet (120 meters) allows power to increase from 2 MW to 5 MW (a factor of 2.5).

Turbine power increases with the cube of wind velocity. For example, a turbine at a site with an average wind speed of 16 mph would produce 50 percent more electricity than the same turbine at a site with average wind speeds of 14 mph.

These two fundamental physical relationships are behind the drive to scale up the physical size of turbines. A larger rotor diameter allows a single turbine to generate more electricity, providing better return on installation cost. And because wind speed and consistency both increase with height, taller turbines produce a higher and more consistent supply of electricity.

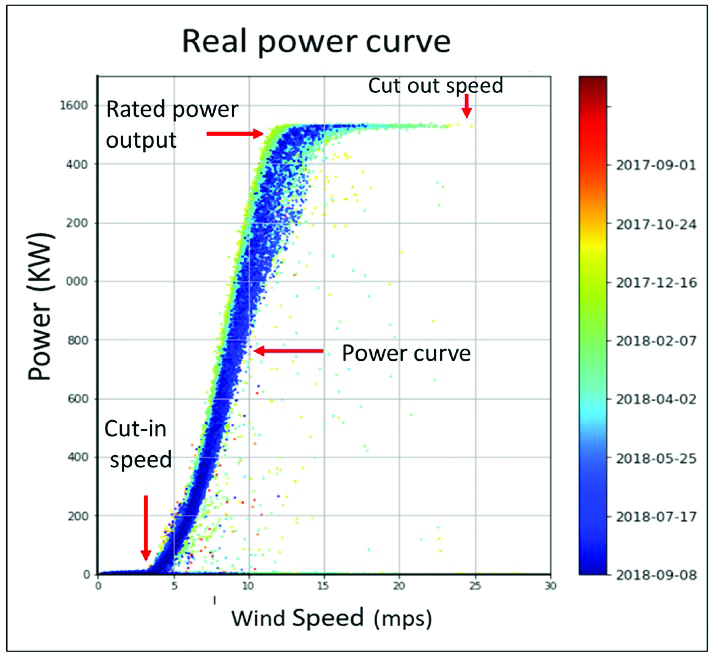

A given design operates with a range of wind speeds. Below the cut-in wind speed, the turbine cannot produce power because the wind does not transmit enough energy to overcome the friction in the drivetrain. At the rated output wind speed, the turbine produces its peak power (its rated power). At the cut-out wind speed, the turbine must be stopped to prevent damage. A typical power profile for wind speed is shown in Figure 2.

In addition to an operating range, an installed turbine has a capacity factor that reflects its actual power generation. The capacity factor is the annual average of power generated divided by the rated peak power. For example, if a turbine rated at 5 MW produces power at an average of 2 MW, then its capacity factor is 40 percent. In general, a higher capacity factor is preferred, although it may not be advantageous economically. For instance, in a windy location, it will be advantageous to use a large-size generator with the same rotor diameter. This would tend to lower the capacity factor, but it will lead to substantially larger annual production.

Wind-Turbine Technology

Turbines come in several general categories based on orientation and drivetrain type.

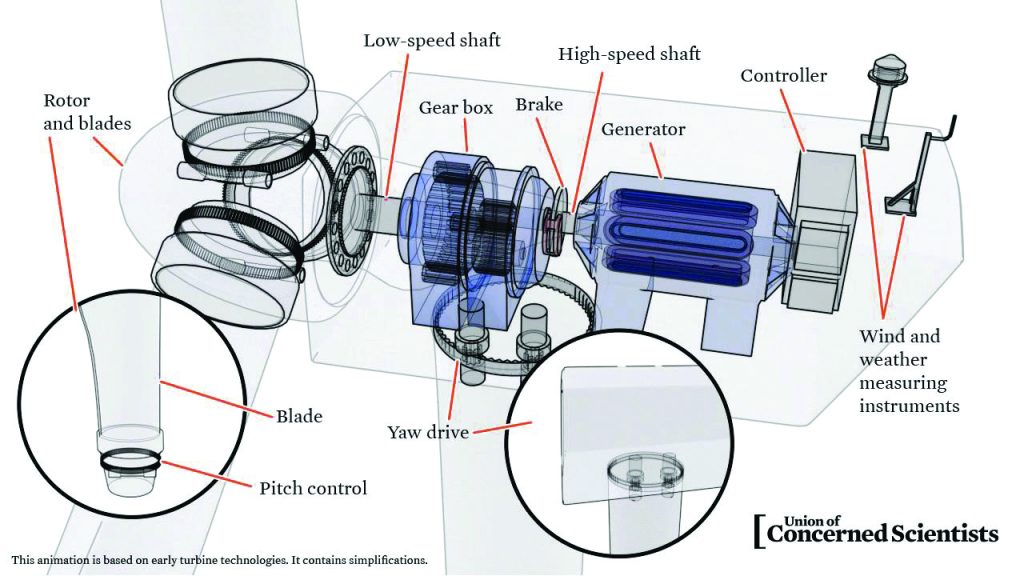

The turbine blades can be oriented around either a vertical or horizontal axis. An advantage of the vertical axis is that blades do not have to be mechanically reoriented when the wind direction changes. Horizontal-axis turbines also come in two general designs. In a downwind design, the blades face away from the incoming wind; in an upwind design, the blades face into the wind (see Figure 3). More than 90 percent of currently installed turbines are of the upwind type, as this design does not create wind shade behind the tower.

For the drivetrain, in a gearbox-drive design, a gearbox is used to increase the speed transmitted from the rotors to the generator. In a direct-drive design, the speed is transmitted directly to an annular generator. Aside from the gearbox, the components are generally similar; however, in a direct-drive turbine, the generator is much bigger because it must rotate at the same speed as the turbine blades.

The wind-turbine components that experience friction and wear and require lubrication are the following:

- Pitch bearing (grease).

- Main shaft bearing (grease).

- Gearbox if any (oil).

- Yaw drive (grease).

- Generator bearing (grease).

The pitch drive is used to adjust the angle of the blades. This adjustment is made for two reasons: 1) to capture maximum power from winds below the rated output wind speed or 2) to slow the blades for safe operation at winds above the rated speed. The yaw drive moves the blade and housing assembly (the nacelle) to the optimum direction in relation to the wind. An animation prepared by the Union of Concerned Scientists is helpful in visualizing the action of these drives [2].

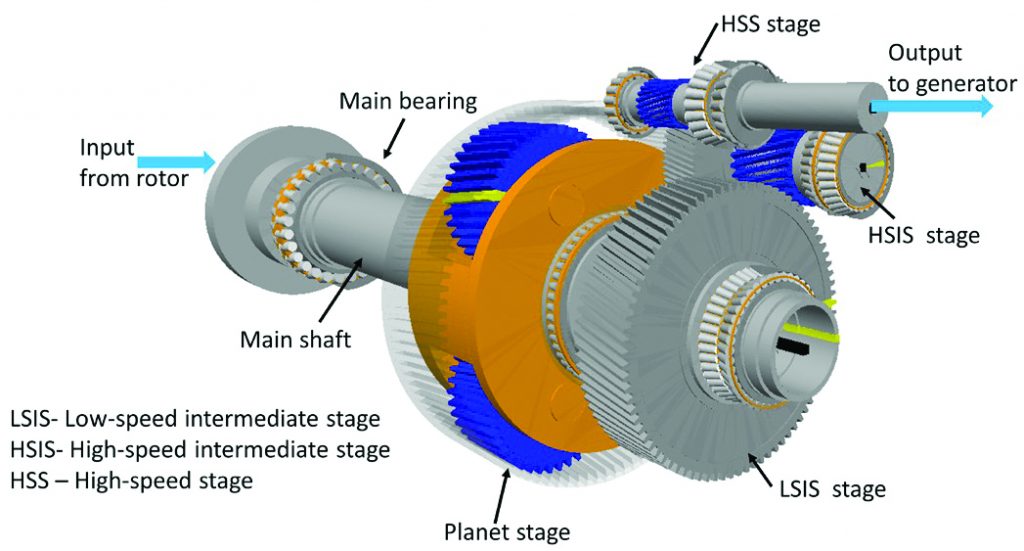

Figure 4 shows a typical three-stage wind turbine gearbox. A planetary stage (bottom left) transfers the torque first to a low-speed intermediate stage (bottom right) and then to a high-speed intermediate stage (middle), which drives a high-speed stage (top) that feeds the generator. Such a design might, for example, convert 14 rpm input from the rotors into 1,500 rpm to the generator; the exact conversion of course depends on the gear ratio. Different bearing types are used in these various components.

Some technical differences should be noted between land-based and offshore turbines. As noted previously, offshore installations account for more than 3 percent of global capacity. Offshore construction presents different challenges, the most obvious being how the structure is anchored. The strategy differs depending on the water depth. For depths less than about 100 feet (30 meters), monopile construction is used. For transitional waters (100-200 feet or 30-60 meters), a cross-braced “jacket” foundation is used. For deeper waters, prototype floating platforms are being tested. The transformer design also is different for different water depths, and in general, offshore installations are moving from gearbox to direct-drive designs.

Another significant difference is size. Without the need to limit noise or accommodate terrain-induced turbulence, designers can pursue truly giant scales. GE has built an offshore design rated at 12 MW, significantly higher than the 2017 average of about 2.3 MW. It is indeed a giant: The rotor diameter is on the scale of the towers of the Golden Gate Bridge, and the surface area of the blade sweep is equivalent to seven American football fields. In this design, the torque is transmitted directly to the generator. Why build such giants? In addition to raising power output, large turbine reduce installation cost. Installing one 12-MW turbine is cheaper than installing six 2-MW ones; thus the final cost per megawatt is lower. For these reasons, and because of the abundance of offshore wind resources, the industry is moving to an emphasis on offshore wind power.

Summary

Wind turbines are the fastest-growing renewable energy source, and wind energy is now cost-competitive with nonrenewable resources. Growth in generating capacity is concentrated in five to 10 states, notably Texas. Five companies lead in the installation market. The field of turbine manufacturers is crowded, but GE Renewable Energy and Vestas are clear leaders. Increasingly, capacity is being purchased by entities other than utilities, and offshore installations are becoming more attractive and viable.

In terms of technology, turbine design focuses on optimizing power output by focusing on two key parameters: blade length and average wind speed. The latter is affected by surface terrain and varies spatially, directionally and seasonally. The effectiveness of a particular installation is quantified by a capacity factor: the ratio of actual annual energy output to the theoretical maximum output. A number of basic designs are in use, but most commercial installations use a horizontal axis, upwind-facing design. Turbines are becoming ever larger, in both physical size and generating capacity, in order to capture more stable winds and to maximize return on installation costs.

Editor’s note

The article is based on a webinar by Dr. Harpal Singh. Dr. Singh is a senior scientist at Sentient Science where he is engaged in wind turbine and aerospace-related mechanical and materials science research involving tribology, materials characterization, and failure analysis. Dr. Singh has more than six years of experience in the field of tribology and metallic materials. He holds a patent, several peer-reviewed publications, and two best paper awards from STLE in the field of solid lubricants. He earned his doctorate in mechanical engineering from the University of Akron, Ohio. His research was focused on the mechanical, material, and tribological properties of materials and coatings used in wind, automotive, and aerospace applications. His expertise includes materials characterization, tribological testing, coatings, and failure analysis.

References

- Global Wind Report 2018, by Global Wind Energy Council. Available at https://gwec.net/global-wind-report-2018/.

- “How Wind Energy Works,” by the Union of Concerned Scientists. Available at www.ucsusa.org/clean-energy/renewable-energy/how-wind-energy-works.