Brüel & Kjær Vibro, one of the leading worldwide independent suppliers of condition monitoring solutions for rotating machinery, has launched the VIBROPORT 8000 (VP-8000) Portable Vibration Analyzer for rotating and reciprocating equipment.

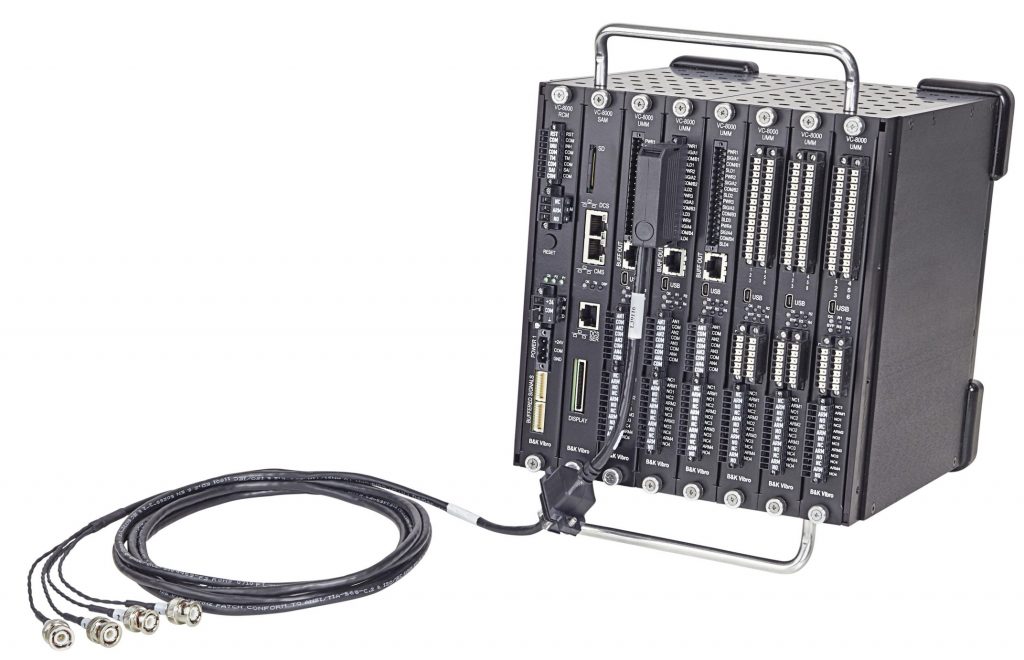

The new VP-8000 is a specially configured and packaged version of Brüel & Kjær Vibro’s VC-8000, which is an internationally renowned machinery protection system. The VP-8000 features the same universal measurement modules (UMMs) and the rugged and field-proven design as the VC-8000, but it is optimized for portable dynamic data collection and diagnostics.

There is a wide range of applications for VP-8000 for both plant operators and service providers. It is ideal for verifying the condition of machines after a turnaround and those repaired prior to service start-up. It is also used for steady-state and transient condition monitoring (i.e. during a run up and coast down) for observation and trending of machines following an event (e.g. operational process changes or machine fault detection). VP-8000 can also be used as a mobile platform for monitoring a number of machines within the plant that are not instrumented or that only have protection. VP-8000 can be used both as a portable data collector and as an analyzer. Advanced diagnostics offered by Brüel & Kjær Vibro’s best-in-class SETPOINT® condition monitoring software (CMS) include:

- Shaft/bearing: Orbits, full spectra, shaft centerline plots, Bode plots, polar plots, etc.

- Reciprocating compressor: PV plots, rod load, rod reversal, impact monitoring, etc.

- Two-plane balancing.

The VP-8000 connects to rotating machines and captures real-time vibration and process data for immediate monitoring and diagnosis of equipment health or via the VP-8000 flight recorder for storing data for remote analysis. The VP-8000 can be connected to the buffered outputs of most machine protection systems with BNC outputs, or it can be used with temporarily mounted sensors on machines where there is no monitoring system. Data can also be exported to the OSIsoft PI data historian.

“The VC-8000 is normally permanently installed and connected to one or several rotating or reciprocating machines, but customers found that the system’s ease of use, outstanding data acquisition capability, and robustness enabled use as a portable data acquisition system,” said Albert Vontz, head of business unit industrial, Brüel & Kjær Vibro. “In its portable form, the VP-8000 user enjoys multiple methods of data acquisition. They can connect to their existing machinery protection systems to immediately view, log, and share all data needed to understand machinery behaviors. The VP-8000 can be connected to machines for hours, days, or months and all the while it will collect valuable data — even without a computer connected to the rack. The system operates equally well in standalone modes, linked to a laptop, or to an OSIsoft PI historian.”

The VP-8000’s patented intelligent waveform capture ensures critical waveforms are never missed. It can rapidly capture and trend data at 80 ms and is versatile enough to scale from 1 hour to 1000-plus hours of data capture. With 24-channels, the VP-8000 features 32 GB removable SD storage, 256 GB internal SSD storage, resolution from 400 to 12,800 spectral lines, and sampling from 16 to 1,024 samples per second.

MORE INFO www.bkvibro.com