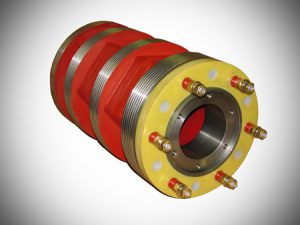

Morgan Advanced Materials Electrical Carbon business announces that its quality engineered slip rings, can reduce down time and improve the life of equipment whilst reducing maintenance time and costs. Made with the latest innovations in resin compounds Morgan’s molded slip rings encapsulate all current carrying components, inhibit harmful dust intrusion and contamination, and increase the dielectric strength. They can also be specially engineered to improve airflow, which reduces the amount of thermal build up.

These key benefits make them ideal for use in wind turbines as well as numerous other industrial, traction power and signal transmission applications. Slip rings are offered in a wide range of both standard and customized sizes and designs and can be manufactured in either molded or fabricated versions.

High quality slip ring transmitter systems are available in 1 to 8 rings from Morgan, with outside diameters ranging from 24 to 500 mm and feature high mechanical, thermal resistance and excellent dielectric properties.