An innovative carbon brush holder, set to reduce maintenance costs for doubly fed generators in wind turbines, will be introduced by Carbex at the AWEA WINDPOWER 2013 exhibition in Chicago, May 5 – 8 (booth no. 1011).

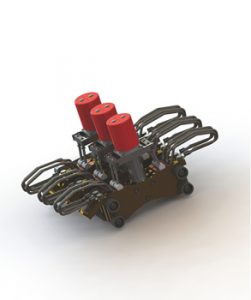

The Carbex V-type brush holder ensures that all the carbon brushes push against the slip ring with equal force, preventing uneven wear and premature brush replacement. This also reduces electrical and mechanical losses, lowering the temperature of the carbon brushes and improving their lubricating properties. In addition, remote monitoring is simplified, as only one switch per phase is required.

A traditional brush holder set-up includes a number of brushes that are fitted around the slip ring and adjusted individually. Brushes typically wear unevenly as each has different pressure against the slip ring.

The V-type holder eliminates these variations. The brushes are fitted and locked into position in single brush pockets. Through equal load on all carbon brushes, and lower temperature, the V-type holder gives longer life to the brushes, resulting in longer service intervals. This can mean substantial savings on maintenance, as visits to remote locations can be very costly, particularly in offshore applications.

The design of the V-type holder simplifies fitting and facilitates service, saving time while on site. The compact holder is located just inside the inspection hatch of the slip ring compartment for easy access. Only one adjustment is required for the holder. There is no need to adjust the angle and contact surface of the individual brushes.

The Carbex V-type holder is patent-pending in the U.S., EU and China. It is available for all common designs of doubly fed generators in the market. The design is modified for the requirements of each OEM to fit the existing bolt holes in the shield. For more information, visit www.carbex.eu.