The wind industry is undergoing a period of unprecedented growth as part of the nation’s efforts to fully decarbonize the U.S. energy system by 2035. Tens of thousands of wind turbines are expected to be installed over the next few years — and with this boost in numbers comes both an increase in expected frequency and greater public scrutiny over wind turbine fires.

Fire risk and wind turbines

Wind-turbine fires are relatively rare. While the exact statistics cannot be determined from publicly available data, the number of wind turbines estimated to catch fire per year varies between 1-in-2,000 to 1-in-15,000. However, as more turbines are installed and existing assets age, the frequency of wind-turbine fires is likely to increase.

While steps already are being taken to “design out” as much fire risk as possible for new turbines, older turbines are likely to retain features that could put the asset at risk.

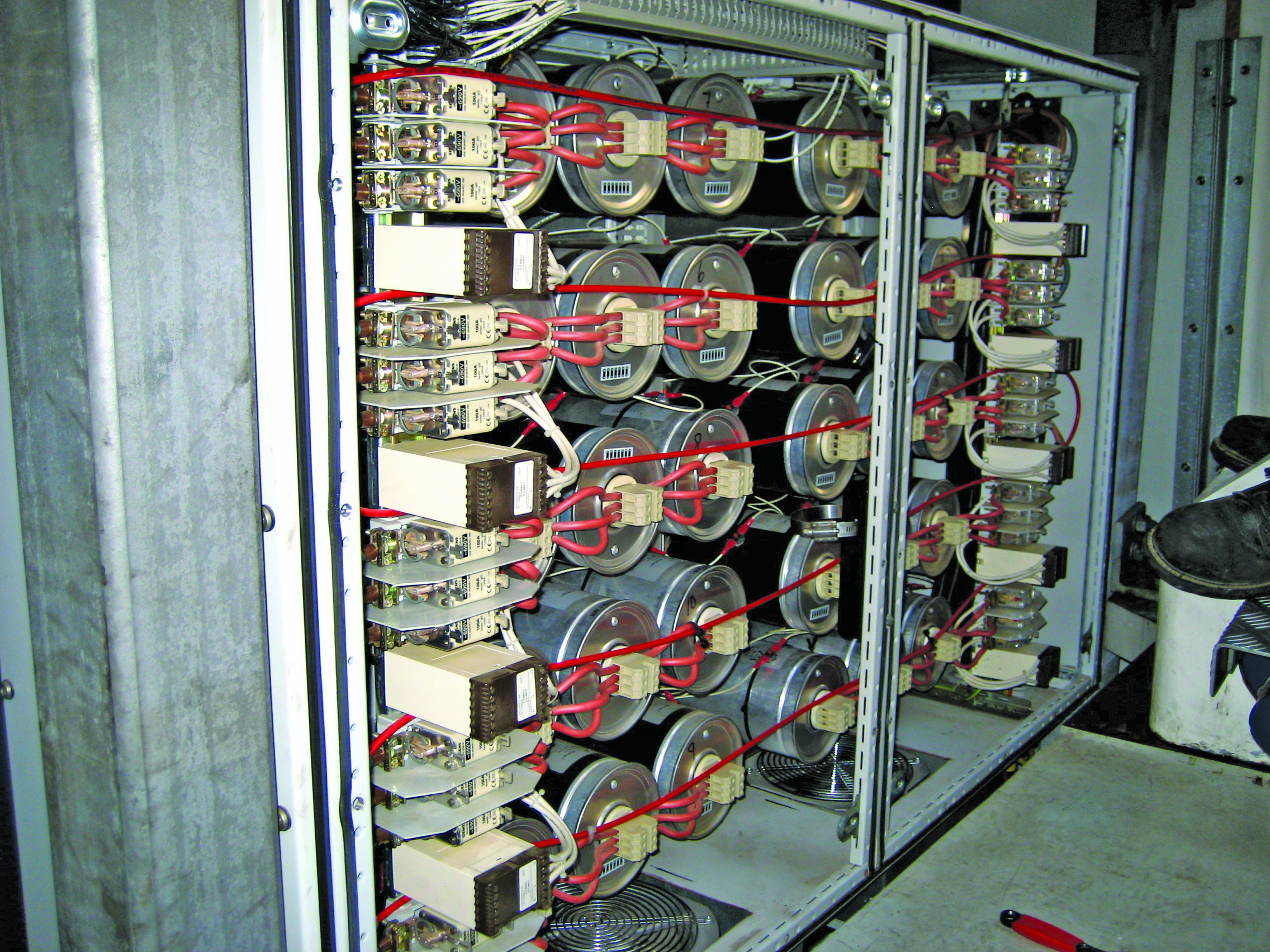

Additionally, while newer turbines have features such as lightning protection systems being installed during production, many high-risk features cannot be removed from the design without seriously affecting generation. For example, convertor and capacitor cabinets and transformers are two of the most common points of ignition for a wind turbine, as an electrical failure can result in the production of sparks and heat. However, these parts are vital for the turbine to convert wind energy into electricity.

As fire risk cannot be completely designed out, it stands to reason that wind-farm owner-operators should act to prevent their assets from catching fire once operational — or face serious consequences.

The cost of a wind-turbine fire

A wind-turbine fire can cost upwards of $8 million, according to insurance experts quoted in Firetrace’s recent report, “Reducing Fire Risk.” As most wind-turbine towers exceed 250 feet, they are often out-of-range for ground-based firefighting. Sending a team up to fight the fire presents a significant health and safety risk. Therefore, if no fire suppression system is in place, it will be left to burn out, irreparably damaging the turbine.

While insurance frequently covers fire damage, the cost of managing increasingly large claims is pushing the market into a “hard” state, wherein premiums are raised and policies become much stricter. Acting to reduce fire risk could enable insurers to offer more favorable policies without taking on excess risk — reducing overall costs for wind-farm owner-operators.

Fire risk is not only a concern for the wind farm’s balance sheet. A wind-turbine fire can spread to the surrounding environment, sparking wildfires and potentially spreading into nearby communities. As such, stakeholders at the government and community level are likely to push for regulatory changes to ensure any wind-turbine fires are suppressed before the flames can spread beyond the asset.

What are the regulations for fire prevention, detection, and suppression?

Currently, all power plants across the U.S. must comply with National Fire Protection Association (NFPA) standards in order to ensure their operations are sufficiently safe. Coal, gas, and nuclear are all regulated to ensure sufficient fire detection and suppression systems are installed in order to guarantee the safety of on-site personnel.

However, wind is not regulated to the same degree. In part, this is due to the relative “newness” of wind compared to other power-generation types. Coal- and gas-run generators have been used to produce electricity for centuries with nuclear in widescale use across the United States since the 1950s.

The wind industry also has a much safer record than coal, gas, or nuclear, which all have had historical fire incidents with multiple fatalities that prompted swift regulation.

As such, while NFPA 850, the code for fire safety in power generation, does provide a standard for wind-turbine fire safety, fire detection and suppression systems are only recommended and not required.

However, a growing number of both local and state governments in the U.S. are acknowledging that fire suppression in wind is a necessary step to safeguard wind projects and the surrounding environment and property in the event of a fire.

In New Hampshire, for example, a legal dispute was sparked between the fire marshal and a leading utility over whether a wind farm followed the state’s fire code. This dispute was resolved once the utility retrofitted fire suppression systems to the project.

Outside the U.S., a number of countries and regions are starting to mandate fire suppression for new projects. For example, German standards from the Vertrauen durch Sicherheit (VdS) and DNV GL both include fire protection and suppression in their renewables project certification guidelines.

In Canada’s Ontario province, fire suppression is not only mandated for installation in new energy projects but is also required to be retrofitted to existing sites.

It is only a matter of time before a similar level of scrutiny over fire protection is rolled out on a national scale in the U.S. The wind industry must ensure it is proactive in ensuring it is following best practice for preventing and suppressing fire.

Proactively managing fire risk doesn’t just enable owner-operators to prepare for upcoming regulations — it also can help maintain positive relations with local stakeholders and surrounding communities. By taking steps to prevent and suppress fires, owner-operators can avert damage to not only individual assets, but the wider industry’s reputation for safety and environmental protection.”