The wind sector continues to expand at pace, with tens of thousands of new turbines installed globally each year. In parallel, average (and maximum) blade sizes have increased significantly. The industry is witnessing widespread deployment of 7-MW to 15-MW machines onshore and offshore, with some developers installing turbines of up to 15-MW onshore and 25-MW offshore. At the extreme end of the scale, Chinese manufacturer Mingyang recently unveiled plans for a massive 50-MW floating wind turbine.

Larger blades generally translate into higher energy yields and increased revenue potential. However, they also introduce elevated operational risk, particularly in relation to blade maintenance, repair costs, catastrophic failures, and turbine — or entire fleet — downtime.

When blade damage escalates into full blade failure, the associated costs increase dramatically. Blade replacement costs can spiral to approximately $500,000 for onshore turbines and $1 million or more offshore, compared with a typical blade repair cost ranging between $30,000 and $100,000, respectively.

Beyond the immediate repair or replacement expenses, blade failures can also result in substantial indirect costs, including business interruption and long-term reputational damage for asset owners and operators.

Given the multifaceted value of these assets and the significant financial impact of unplanned downtime, it is unsurprising that wind-sector stakeholders are increasingly focused on preventative maintenance strategies. Proactive condition monitoring has become essential, since early intervention is substantially more effective and cost-efficient than reactive repairs or replacements.

Drone Deployment

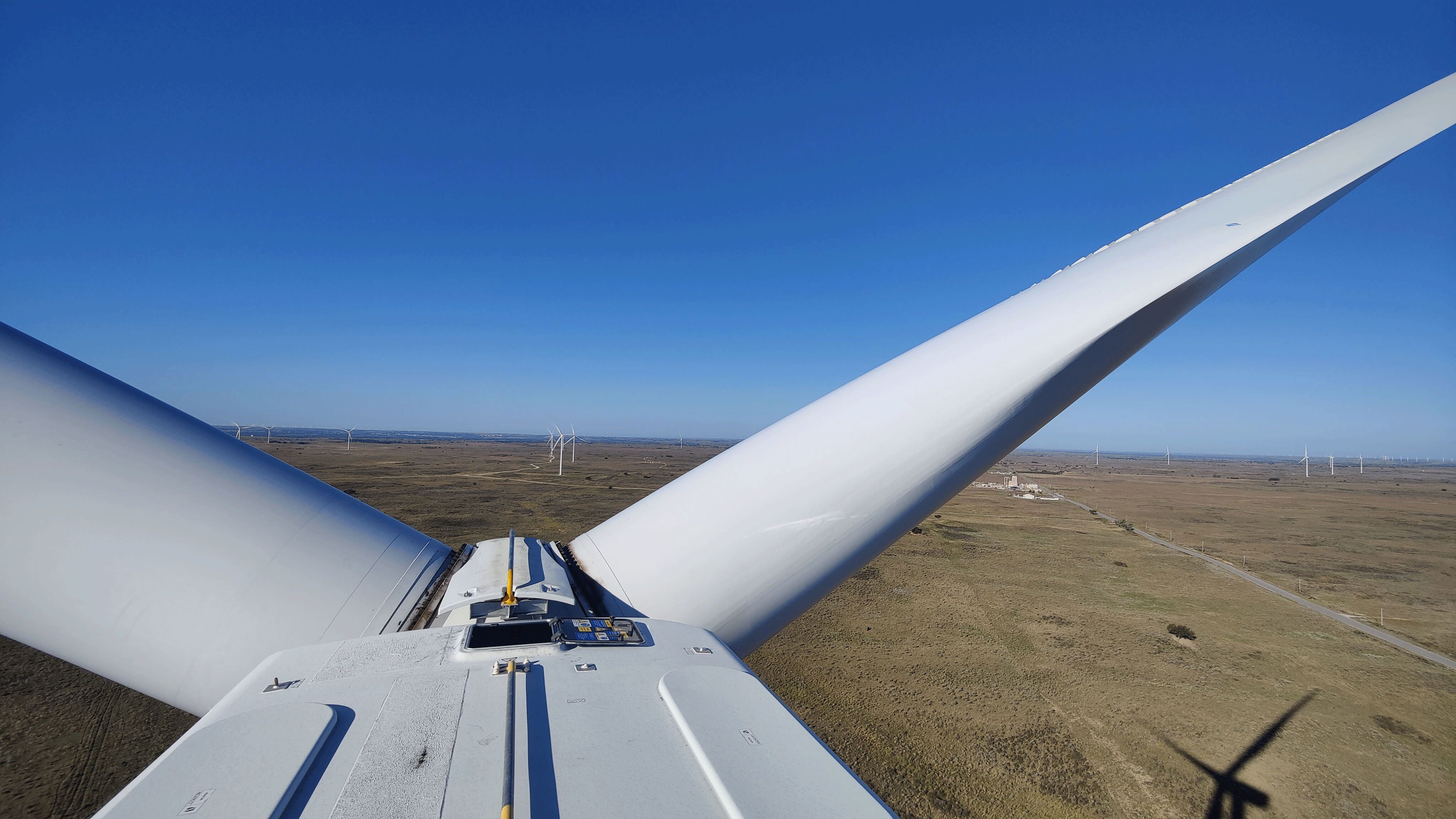

Drone inspections have become one of the most widely adopted blade condition monitoring methods and are typically conducted on an annual basis. Advances in drone technology have made these inspections effective at identifying clearly visible, slow-developing defects on the external surface of blades.

For asset managers, drones have delivered a solid return on investment, given their relatively low cost, and have helped identify damage that might otherwise remain undetected during ground-based inspections. However, despite widespread use, drone inspections have inherent limitations that must be acknowledged.

Drones are restricted to detecting a limited number of external failure modes and are unable to assess all areas of a blade’s exterior. More critically, they cannot identify internal defects at all, such as subsurface cracking, structural degradation, or issues within the pitch-bearing. These limitations mean that significant risks and damage routinely remain undetected.

In addition, drones do not capture changes in blade behavior over time — an important indicator of emerging issues. Such behavioral changes may result from environmental degradation, extreme weather exposure, manufacturing defects, or material fatigue associated with blade age. Over the medium- to long-term, these factors can lead to reduced turbine performance, increased mechanical stress on components such as the rotor and drivetrain, and ultimately, turbine failure.

While these constraints highlight the limitations of drone technology, they do not diminish its underlying value. Rather than replacing drones, the industry should view them as a single component within a broader blade condition monitoring strategy, complemented by systems capable of addressing what visual inspections cannot.

Combining with Blade CMS

Integrating drone inspections with blade condition monitoring systems (CMS) enables a far more comprehensive assessment of blade health. This combined approach enhances inspection accuracy and provides a more holistic and all-encompassing understanding of blade condition. Internal CMS technologies — such as vibration and displacement sensors installed within the blade — complement the strengths of drone-based inspections.

Vibration-based CMS, for example, monitors for anomalies that indicate blade imbalance, which may result from ice accumulation or physical damage. A key advantage of vibration monitoring is its ability to localize the source of an issue with high precision. This enables operators to implement targeted interventions, reducing repair time, downtime, and associated costs. Displacement-based CMS, meanwhile, supports the early detection of structural degradation by measuring minute internal movements between the blade and the hub. These movements are often imperceptible during visual inspections but can signal serious underlying issues. In many cases, displacement sensors can identify risks up to a year before they culminate in a problematic blade failure.

The Key: A Blended Approach

To date, the wind-power industry has not identified a single solution capable of detecting the full spectrum of blade-failure modes. Given the diversity of contributing factors — ranging from turbine model, environmental conditions and manufacturing defects to operational age — this is unsurprising.

The variety of geographies and climates in which turbines operate further compounds this challenge.

The good news is drones and blade CMS technologies, when deployed together, can provide highly robust and comprehensive coverage of both external and internal blade conditions.

Working in tandem, these technologies enable near real-time, end-to-end blade monitoring. This integrated approach offers owners, operators, and asset managers the clarity and confidence required to safeguard performance, reduce risk, and protect long-term asset value.