Energy solutions leader Aggreko has supported Jaeger Maritime Solutions in deploying a bubble curtain for an offshore wind-farm project situated off the coast of France. Before driving the turbine’s piles into the seabed, a bubble curtain was required to absorb and disperse sound, safeguarding surrounding marine ecosystems from harmful noise levels and fine particles produced by underwater construction.

This was when Jaeger Maritime contacted Aggreko to supply a compressed air solution capable of powering the bubble curtain for its vessel.“Throughout the construction of offshore wind farms, protecting marine life is a top priority. We required a partner with proven project management expertise, who could not only supply 100 percent oil-free air compressors, but also manage the logistics and performance monitoring offshore,” said David Baum, Jaeger Maritime Solutions managing director. “Aggreko delivered a solution that was both technically sound and environmentally conscious, with their team of expert engineers with us every step of the way.”

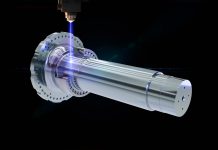

With both businesses committed to protecting marine life while supporting the transition to a more efficient, sustainable future, Aggreko leveraged its Greener Upgrades™ portfolio to supply a bespoke package of 18 stage V 100% oil-free air compressors, along with a 60 kVA Stage V generator to power the winch, positioned at the stern of the vessel, used to reel on the bubble curtain.

The compressors were connected to hoses that delivered the volume and pressure needed to form the bubble curtain, minimizing harmful emissions in the process. The Aggreko Remote Monitoring (ARM) service was also provided to enable real-time, offshore monitoring of the air compressor’s performance.

100 percent oil-free air compressors eliminate the need for airborne oil and prevent the risk of contamination during critical construction activities. Aggreko’s range of 100 percent oil-free air compressors meet the strict ISO 8573-1 Class 0 certification, ensuring the highest level of air purity required for sensitive applications like bubble curtains. “This project was a great example of environmentally responsible offshore construction, and we remain committed to contributing to the continued development of renewable energy infrastructure in Europe,” said Michel Maaskant, renewable energy specialist at Aggreko.

More info www.aggreko.com