Artificial intelligence (AI) has been receiving a lot of attention in recent years, and for good reason; this technology has the potential to revolutionize nearly every industry. The renewable-energy sector is no exception. In 2021, the World Economic Forum published a paper discussing how AI could be harnessed to accelerate the transition to renewable energy, covering aspects as diverse as governance, design, and risk management.

Less than two years later, AI use cases are already being employed effectively in many aspects of wind energy production — with promising results.

Wind energy is one of the most efficient and sustainable forms of renewable energy — and currently the fastest-growing source of electricity in the world. However, this swift expansion leaves the wind sector facing significant challenges in terms of efficiency, scaling, and costs.

Artificial intelligence can help the wind-energy sector address these challenges, offering immediate improvements on several fronts. And as the industry matures and advances, exploration of new applications for AI-driven technologies are likely to offer additional pathways for wind-power innovation.

In this article, we’ll explore some of the most exciting ways AI-driven tools are being used within the wind-energy sector, why this technology is likely to become even more integral to the industry in the coming years, and how AI technology can keep projects on time and on budget.

Weather Forecasting and Wind Analysis

Artificial intelligence enables constant, consistent, and near-instantaneous analysis of vast amounts of environmental data — empowering accurate prediction and real-time adjustment to current weather and wind conditions. This leads to improved planning and operational efficiency, eliminates unnecessary shutdowns due to weather or environmental hazards, and reduces equipment malfunction and damage caused by atmospheric conditions.

Maintenance Optimization

Some wind-energy providers are already using AI to predict maintenance needs and optimize turbine performance. By monitoring wind conditions and cross-referencing environmental data with records of past maintenance, AI can identify patterns that may indicate a need for future maintenance or repair. This information can then be used to create an optimized schedule, identifying exactly when (and how often) maintenance should be performed.

Turbine Monitoring and Inspection

Inspection of wind turbines is a critical task to ensure their safe and efficient operation. AI-driven tools can be used to monitor the performance of turbines in real-time, as well as to automate turbine inspection. When combined with powerful computer vision or cutting-edge robotics, these tools often reveal defects that are easily overlooked by human inspectors, identifying potential problems while providing powerful insights that boost operational efficiency.

AI-driven tools not only enhance the safety of turbine operations, but their use also mitigates exposure to risks caused by failed equipment — avoiding costly downtime, while ensuring that turbines are operating at peak efficiency.

Wind Systems Production Optimization

Because generation of electricity from wind power is intermittent, increased integration of wind systems into existing power grids poses challenges to flexibility, safety, and stability of current power systems. Large-scale expansion of wind-power generation hinges on optimized control and operation of wind turbines and power systems — which, in turn, hinges on crucially accurate analysis and forecasting of weather, wind speed, and their subsequent effects on wind power generation.

As use of renewable power continues to evolve and expand (both in literal terms, and as a share of the global power supply), more accurate predictions for solar and wind power generation become ever more critical for forecasting power demand, improving production uptime, and boosting energy system and storage capacities.

Wind-Power Use Forecasting and Scheduling

AI definitely has a role to play in effective energy dispatch and usage scheduling. Demand forecasting is a complex endeavor; when poorly executed, it can trigger power blackouts, brownout scheduling, and/or result in renewable curtailment.

AI is good at detecting complex usage patterns and flagging potential concerns. Through analysis of historic consumption and usage data, today’s machine learning tools can also predict consumer demand at both the individual and aggregate level.

According to recent studies, artificial intelligence accurately predicts wind-power generation, energy production, and power and usage demand, enabling smart grids to store and transmit power more safely, efficiently, and sustainably. Improved accuracy of forecasting models supported by artificial intelligence and machine learning tools empowers operators to methodically balance supply and demand on the electricity grid — significantly reducing the cost of renewable energy provision.

Remote and Offshore Operations

Offshore wind farms are an important source of renewable energy, and their efficient operation is critical for reaching global climate goals. AI can play a key role in remote monitoring of both onshore and offshore wind farms, ensuring that hard-to-access locations are running smoothly.

When leveraged for the purposes described above, AI reduces the need for onsite monitoring or staffing for remote locations — significantly reducing the cost of operation for offshore wind farms. Improved logistic and production efficiency further maximizes site output, increases profit margins for offshore wind production, and improves site monitoring logistics and operational feasibility — qualities critical to continued growth and sustainability of global wind energy adoption.

One of the less-considered ways in which AI can benefit the wind-energy sector is in the process of scaling physical growth.

The cost of constructing wind-energy systems and wind farms has been a major historic barrier to the widespread adoption of renewable energy. Location and geographic challenges abound — with onshore and offshore sites presenting their own sets of logistical hurdles and variations. The approach to installation of building-integrated wind turbines deviates drastically from best practices for installation of free-standing turbines — and each project also arrives with a host of construction and engineering complexities unique to its specific structure and site location.

Add to all of this the need for intense spatial and physics calculations, environmental and aesthetic analysis, use and installation of specialized equipment, and the unique governmental and regulatory considerations that accompany the construction of large-scale utility infrastructures — and the complexities involved in construction of wind-energy systems begin to add up to their accompanying cost.

The powerful processing capabilities of artificial intelligence make it possible to address these complexities quickly and efficiently — while minimizing project expenses, across several cost silos.

Site Selection and Environmental Analysis

Turbine placement and siting of wind-harvesting farms have a major impact on the generation and storage capacity of these renewable power systems. Because of its innate ability to assess and analyze massive amounts of relevant geographical and environmental data, many companies are already leveraging AI to identify sites with the most favorable wind resources and conditions — as well as to secure land and spaces with the best access to existing grid infrastructure, for future development.

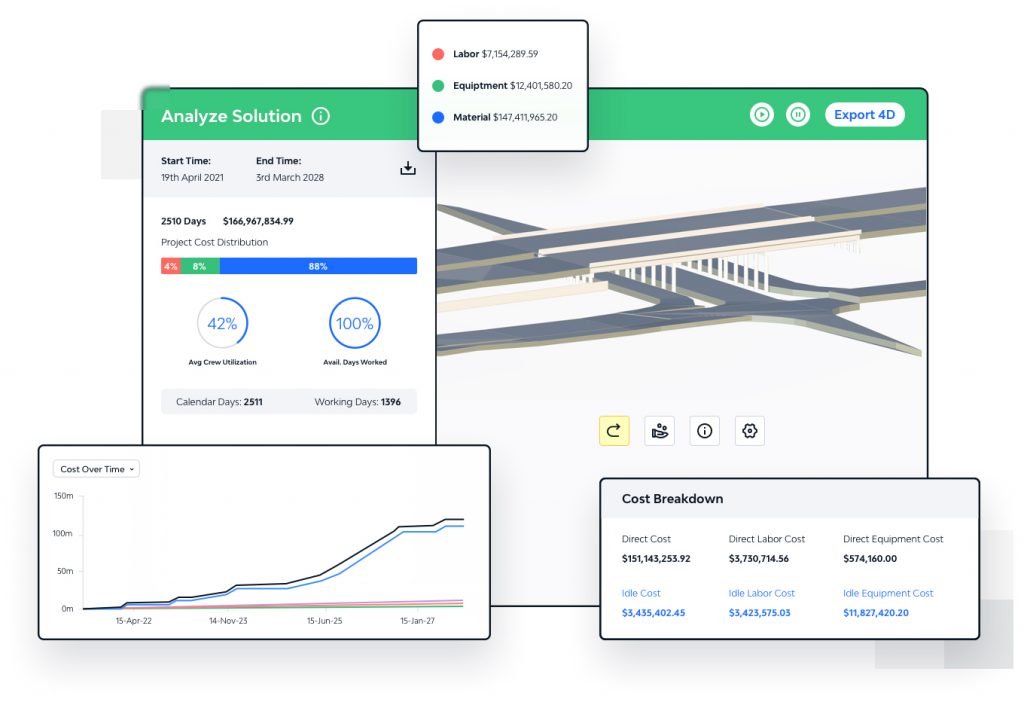

Generative Design and Preconstruction Planning

AI-driven iterative and 4D design can help providers innovate, generating detailed construction plans, schedules, and “digital twin” site models and equipment designs — all tailored to site-specific conditions and restrictions — before ever breaking ground.

Virtual models of proposed wind farms can be used to identify potential issues and optimize turbine layout and efficiencies in the pre-construction phase. This saves time and money, eliminating potential delays and costly adjustments to the project plan and scope of work. AI-driven planning also reduces the need for on-site customization and adjustment, post-construction — at a drastic reduction in cost.

Wind Systems Construction Optimization

Recent advances in artificial intelligence have introduced solutions that can reduce the cost of major infrastructure construction significantly; for many large-scale and complex projects, by as much as 30 percent.

In the wind-energy sector specifically, AI presents more efficient methods for optimization of design, construction, and installation of wind-turbine systems. For example, GE recently announced their use of AI-based tools to analyze installation logistics resulted in a 10 percent reduction of expenses for wind turbine installation — a global cost savings totaling a potential $25 billion over the next 10 years.

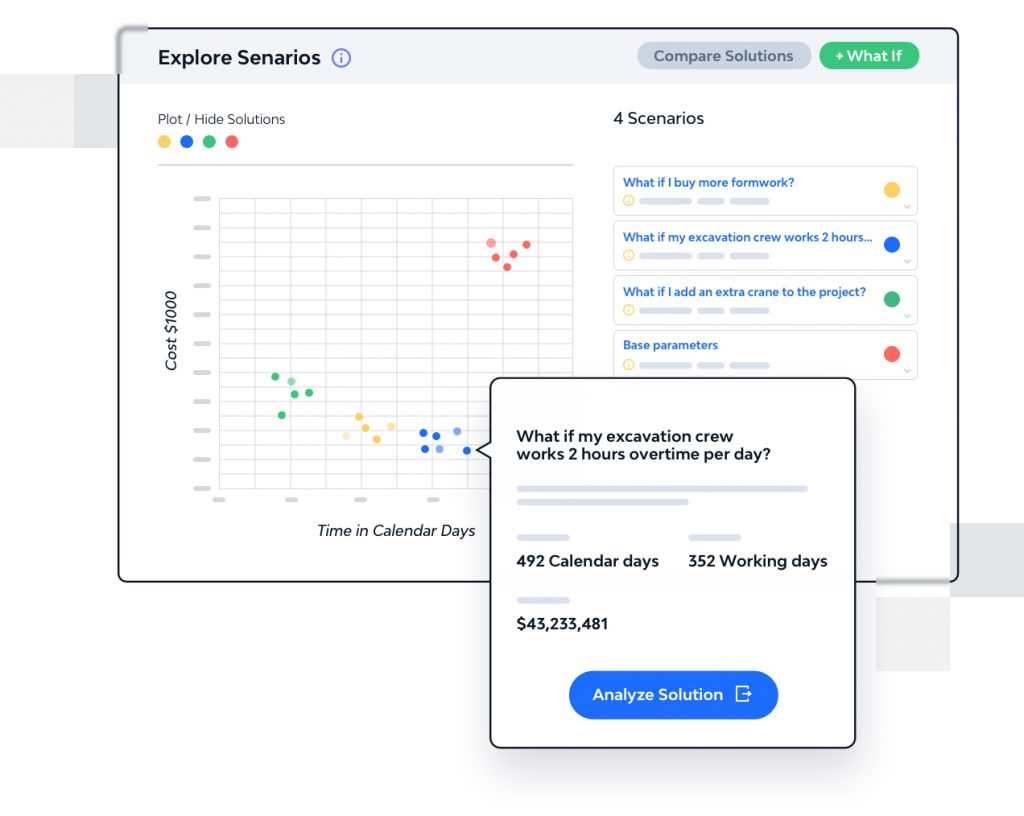

Project Build and Installation Recovery

When construction of wind-energy infrastructure or turbine installation goes sideways, resulting delays can cost millions of dollars per day. AI-driven tools for construction optimization can reallocate valuable resources to circumvent spiraling delays — suggesting options for task, equipment, or labor resequencing that keep a major project moving forward. With so much at stake, and so many moving parts, maintaining progression is critical — making on-the-go scheduling adjustments and speedy project recovery backed by AI an invaluable asset.

By using AI tools like ALICE Technologies for project recovery and construction optimization, wind-energy providers can eliminate delays, minimize build cost, and improve project time-to-completion when the unforeseen occurs. They’ll also boost overall performance throughout the entire project lifecycle — maximizing wind-energy output, while minimizing operational expense and risk.

To succeed at the global goal of achieving net-zero by 2050, the renewable energy sector needs to eliminate emissions completely. Bloomberg NEF’s New Energy Outlook 2020 emphasized that by 2050, solar and wind could provide 56 percent of global power — with wind clocking a massive 4.6 TW. PNAS determined wind could feasibly provide 5.75 TW — a whopping half of the world’s all-purpose power — in a 2030 clean-energy scenario. These scenarios are possible under regulatory policies and guidance currently in play — with no further policy support. This is a solid testament to the fact that the economics of renewable energy storage and systems have evolved to be significant drivers of global power sustainability and decarbonization efforts — even without robust carbon pricing or unified net-zero targets.

Overall, AI holds great promise for reducing the cost of constructing wind-energy systems and wind farms, helping get projects back on track and keeping them there, and supporting the industry as it expands its global reach in sustainable energy production. As these technologies continue to develop, additional innovation can be expected — introducing further improvements beneficial to the wind-energy sector, and its continued evolution toward a sustainable future.

About the author

Dr. René Morkos is an adjunct professor at Stanford University and CEO of ALICE Technologies. Inventor of the world’s first Generative Construction Simulator and Optimizer, Morkos obtained his Ph.D. in artificial intelligence for construction as a Charles H. Leavell Fellow at Stanford University, where he teaches in the Civil and Environmental Engineering department. He is a second-generation civil engineer, with more than 23 years of experience in construction. He has worked as a project manager on reconstruction efforts in Afghanistan, automation of a $350 million gas refinery expansion in Abu Dhabi, construction of an underwater pipeline, implementation of ERP systems, and various virtual design and construction projects. Morkos founded ALICE technologies in 2015; its mission is to improve standards of living by reducing the cost of construction and infrastructure development by at least 25 percent worldwide.