As the wind-energy industry continues to grow, the need for qualified technicians will be of paramount importance.

Where most technician training programs are 12 weeks or more, Siemens Gamesa has been able to cut that training time by a fourth at its Wind Academy training facility in Orlando, Florida.

“The facility is what Siemens Gamesa uses to train all of its technicians, from new hires with limited to no experience in the industry, all the way up to our highly advanced technical skills,” said Kyle DeWitt, director of training for North America. “We run the gamut of training competency here in the center.”

Training for All

For the past two years, the Wind Academy by Siemens Gamesa has extended that training to whoever wants to become a wind technician, according to DeWitt. Before Wind Academy, a future technician would spend months in a program and still need further training before they would see the inside of a turbine, either with Siemens Gamesa or some other OEM.

“The idea behind Wind Academy was to offer a program to individuals, with limited to no experience in the industry, an opportunity for them to — in an accelerated fashion — break into the industry,” he said. “With Wind Academy, you come out of this program, and you are essentially, with maybe a small exception for some nuanced classes from individual OEMs or customers, ready to get to work.”

The three-week program offered by Wind Academy teaches the core of what a technician needs, according to DeWitt.

“We don’t add anything extra, but we haven’t cut anything out that’s necessary,” he said. “The backbone to our program is GWO — all of the Global Wind Organization training certificates. And, what you won’t see at other training programs is the duration, and that’s another huge value proposition.

We can bring a technician in, and within three weeks, you graduate. And, you graduate ready to go to a wind farm.”

Intense Training

Needless to say, compacting all that needed training into a three-week window makes for a busy itinerary, according to DeWitt.

“The days are full, but the feedback we get from our technicians is that the program is intense, but it’s not so intense that you’re not able to retain what you’re learning,” he said. “You don’t come out of here with a certification that you don’t absolutely need.”

Newly minted technicians will leave the program with the basics, although they may need some additional training once they are hired, according to DeWitt.

“Each OEM or each customer might have some nuanced training that they require,” he said. “You can graduate from Wind Academy and then, to get into a Siemens Gamesa wind farm, you may need a couple of extra little things, but they’re very small and minor. But you’re getting the core that will be applicable to any of the OEMs, generally speaking, and most of our customers.”

Cementing a Global Leader Role

The addition of the Wind Academy continues Siemens Gamesa’s vision to be a global leader in renewable energy, according to DeWitt.

“Wind Academy’s philosophy is the same, but focused on technician training,” he said. “We’re trying to be a leader and to lead the industry and the training industry within wind to do what we’re doing. (Before Wind Academy), people who want to be technicians take classes and courses that aren’t critical to getting themselves to work.”

And even though a technician might choose to not work for Siemens Gamesa, that technician is still instilled with the Siemens Gamesa mindset, according to DeWitt.

“That mindset is a safety-first, zero-harm culture, as well as a focus on quality, that we as an OEM want to see in all technicians,” he said.

The Wind Academy’s program is focused mostly on all the GWO basic safety and technical modules, and as part of that partnership with GWO, the course content is constantly being updated and improved, according to DeWitt.

“Together with GWO, Siemens Gamesa — not necessarily Wind Academy — but Siemens Gamesa with Wind Academy reviews what’s being taught, changes in the industry, changes in the regulations that the industry operates under, and we are constantly updating course materials as needed to meet those needs,” he said.

Universal Requirements

And that brings up a challenge that is constantly being debated within the industry: Just what is really required? DeWitt pointed out there is no set of official rules on what classes or certificates are needed in order to work at a certain location.

“What we’re trying to do, again with the overall company’s vision of being a leader and with Wind Academy following suit, we’re trying to define those,” he said. “We, as an OEM, are saying, ‘If you take this list, you are essentially qualified to be on a wind farm.’ To summarize, the challenge of the industry is that there are 1,000 different ways to put a basic qualification package together. We’re trying to define that as an OEM, teach that as Wind Academy, and then urge the industry to follow suit.”

The goal of a universal set of rules may be a challenging one, but DeWitt said he feels the industry is moving in that direction.

“Siemens Gamesa is very much aligned with GWO, and we do see the rest of the industry moving in that direction — not that we’re not all there yet,” he said. “Again, there are a lot of different opinions on what’s necessary and what’s not. Here at Wind Academy and Siemens Gamesa, we’ve really found that right balance between how much coursework you need to take vs. what’s unnecessary. So, I do see the industry moving that way, but it’s obviously a big process.”

Offshore Growth

And as offshore wind grows in North America, it will become even more necessary for the proper training to be offered as more technicians are required. The good news is the certifications for offshore are very similar to onshore, according to DeWitt.

“The only difference is some of the safety training that’s required for offshore, because you’re working on the ocean,” he said. “There are ocean survival-type classes that we are in development on making offerings for. Again, there is no blanket industry standard, but essentially for us, for offshore, Wind Academy would get you almost all the way there. And then, there would have to be some extra survival-type training.”

In the short two years Wind Academy has been available, DeWitt said that about 40 students have gone through the training, and he added that he and the Wind Academy make a point to keep in touch with the students who graduate.

“We genuinely want to know where they get to work,” he said. “That’s the best, when you get the phone call and they say, ‘Thanks, I got my job. I love it.’ And then, when you hear from them a year later, ‘Hey, I’m successful. I’ve moved up into a maintenance-tech level.’ Just watching these students do what they wanted to do, and then knowing that Wind Academy was the on-ramp for them into the industry, is exciting.”

Comprehensive Facility

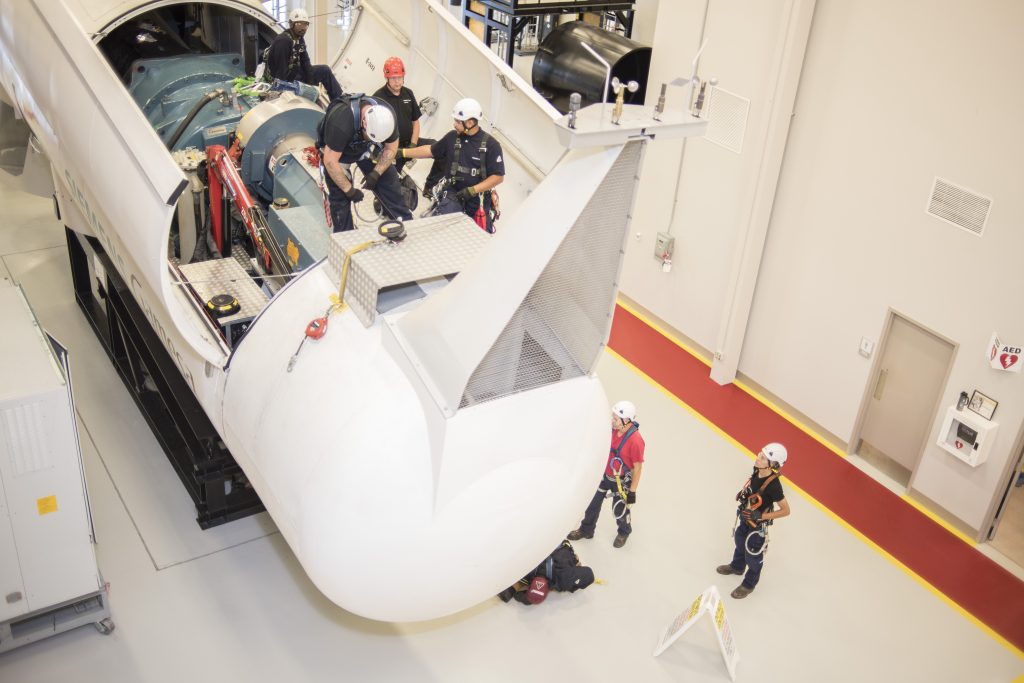

The facility in Orlando, about a mile from the Orlando International Airport, offers some impressive amenities, according to Dewitt. It’s a 40,000 square-foot facility with a section of eight classrooms that can hold 24 people each with one classroom with a capacity of 120. The training bay houses two full-size nacelles — a Siemens direct drive and a Siemens geared — used for technical and safety training.

“We also have three 30-foot-tall climbing towers that we do all of our safety and practical exercises on,” he said. “And then, finally, in the facility, we have two hydraulic and electromechanical labs — which is essentially a wind turbine broken down into pieces that technicians can come practice how to troubleshoot faults, familiarize themselves with the equipment, and learn all the technical details of the job.”

And although there are other facilities dedicated to training wind technicians, DeWitt boasted that Wind Academy is unique.

“The feedback we constantly get is, ‘This place is amazing,’” he said. “It’s really a world-class facility.”

Being Prepared

The “world-class facility” is prepared to be at the ready as the industry continues to grow, according to DeWitt.

“All indication is that the industry is going to continue to expand; the rate of that expansion is maybe up for debate, but I don’t think there’s any question that it’s going to grow,” he said. “And everyone who works in the industry must attend training, whether before you interview to get into the industry, or you get hired and then have to take the training. So, this facility, in general, and Wind Academy as a part of that, are going to be crucial in getting that workforce ramped up. We’re going to have to get creative with capacity, such as how many technicians can we move through here without sacrificing any of the quality of the training.”

Currently, DeWitt said Wind Academy is still building a student base with class sizes consisting of no more than six students.

“Sometimes we have all six seats taken, sometimes we don’t,” he said. “We are actively recruiting and trying to get students enrolled.”

And although there is a cost involved with enrolling at Wind Academy, the main advantage over other training programs boils down to time, according to DeWitt.

“A competitor is going to have you sit in a course or a track for 12 or more weeks, where we’re going to have you out of here in three weeks with all of your internationally recognized certifications, ready to go to a wind farm,” he said. “That difference in time, where you could be on a wind farm working and getting your OJT and earning your paycheck, is where we really try and drive our value proposition.”

More info www.windacademyusa.com