Doubly fed induction generators (DFIGs) are still the most popular generator configuration seen in the wind-energy sector. They offer higher efficiency in variable wind conditions, but an extra component is needed to accomplish this task: the slip ring assembly. This is one extra machine part that has its own maintenance issues, and, therefore, it has to be monitored like the rest of the generator, like the rest of the drive train, and other wind-turbine components.

This case study shows how early detection of slip ring defects can result in a fast, inexpensive repair. If, on the other hand, a slip ring fault is not corrected at an early stage of development, this could lead to a catastrophic failure of the generator.

DFIG Generator Slip Ring Assembly

- The DFIG offers higher performance than previous generations of generators:

- Higher efficiency: It is synchronized to grid with variable wind-turbine speed.

- Better power factor control: Imports and exports reactive power.

- Reduced converter cost: Only 25-30 percent of power passes through the convertor.

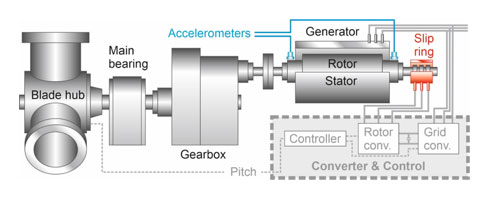

This extra performance is made possible by connecting the rotor windings to the grid via a multi-phase slip ring unit and a voltage converter. The slip ring unit consists of a set of spring-loaded brushes that ride on slip rings mounted on the rotor, for each phase, as shown in Figure 1. If the connection between the slip ring unit and the rotor circuit is defect, this will result in high levels of vibration at both ends of the generator, and could even result in a stator/rotor rub.

Condition Monitoring Strategy

Condition monitoring of wind-turbine generators is performed based on vibration data collected from accelerometers mounted in the load zone of drive end (DE) and non-drive end (NDE) bearings of the generator. A number of generator faults can be detected by these accelerometers, including faults with the slip ring assembly.

Observation and Diagnostics

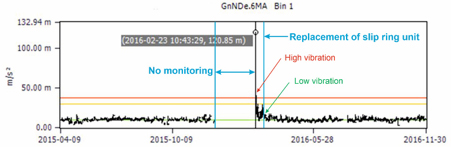

A multi-MW wind turbine in a wind park was operating at full production when the condition monitoring system was temporarily disconnected for approximately two months due to customer related maintenance issues. When the monitoring system went back online, the customer immediately notified the Brüel & Kjær Vibro Surveillance and Diagnostics Service Centre and requested the initial data to be analyzed.

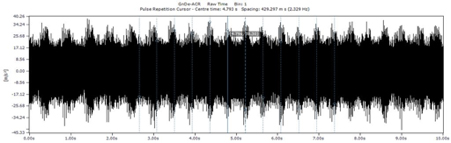

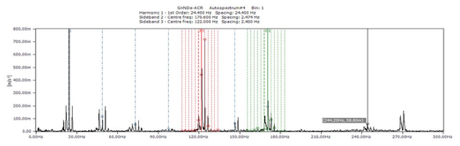

A detailed time waveform and frequency spectrum were looked at shortly after start-up, as shown in Figures 2-3. The increased vibration levels related to generator rotor dynamics indicated a potential problem with generator slip ring unit.

An alarm report was issued immediately followed by a phone conversation with the site manager, explaining the problem. Below are some extractions from the recommendation section of the report on the assessment of maintenance needs:

- Generator inspection is recommended within 1-2 weeks.

- It is recommended to perform an up-tower generator test run with particular focus on the slip ring unit. Check the height of the slip ring brushes to be within the acceptable limits, inspect the condition of the cooling groves, insulation ring, and the current clamps.

- Provide feedback after the maintenance work has been carried out.

Results/Feedback

The customer did a site inspection one day after the report was issued.

After confirming that the slip ring unit and brushes were damaged, these were quickly replaced, and the wind turbine was put back into operation. As seen in Figure 5, the vibration on the generator bearings were lower.

Benefits/Cost Savings Estimation

There are clear benefits in detecting a slip ring fault early. The actual cost and downtime in replacing the slip ring unit is relatively small in relation to the maintenance and downtime associated with a catastrophic failure of the generator.

- Slip ring unit replacement: Approximately 4,000 euros plus a few hours downtime (500-1,000 euros).

- Generator replacement: Approximately 100,000 euros(includes crane) plus downtime (four weeks at 2,000 euros per day), with a total of 156,000 euros.

By avoiding a catastrophic failure of the generator, this gives a savings of 151,000 euros, which does not include labor.

Conclusion

The early fault detection and accurate diagnosis of a rotor circuit malfunction is of crucial importance in regard to applying the proper corrective measures and keeping the generator healthy. This case study shows how, in time, detection of slip ring defects could result in fast and non-expensive repairs. In this way, the total loss of the generator, which often leads to substantial costs, could be avoided.

About the author

Mike Hastings is a senior application engineer with Brüel & Kjær Vibro, where he has been working for the past 32 years. He is currently working with strategic market development, analysis and communications. He is also convener for an ISO work group for creating standards for condition monitoring and diagnostics of machines.