“We are gearbox guys and gearboxes are all we do,” said Bruce Neumiller, CEO of Gearbox Express.

Opened in 2010, Gearbox Express is an independent company that focuses on gearboxes and proactive gearbox life-cycle management with an eye toward speed, quality and customer service.

“Nearly 40 percent of all failures are mainly due to components’ failure with the gearbox contributing the most. The industry is still in its infancy and we are only now learning about the volume of gearboxes that will fail before they reach their anticipated 20 years of useful life,” Neumiller said. “Many customers will need multiple gearboxes during the life of their turbines.”

Targeting a very narrow section of the market was an intentional plan based on research and experience. Neumiller, and his two founding partners, Brian Halverson, COO, and Brian Hastings, CFO, all have solid backgrounds in gearboxes, including work with major global gearbox manufacturers.

“We truly are gearbox guys,” he said. “We focus only on down-tower services, but we can provide technical advice and field support. We don’t compete with any channel partners, including O&M Providers. We are completely independent in the market and we know that repairing gearboxes will become a necessity for OEMs and operators.”

Gearbox Express chose a business model that would support and complement other repair services. “We don’t perform up-tower work on the installed wind turbine, so we are free to work with the operations and maintenance companies, and we don’t manufacture gearboxes, so we have good relationships with most gearbox OEMs and turbine owners. Many owners have multiple makes of gearboxes in their fleet, and with Gearbox Express, they can have one supplier for all of them.”

Along these lines, Gearbox Express saw a need for aftermarket infrastructure, stocking new and used gearboxes from major OEMs such as Gamesa, Vestas, and GE.

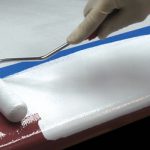

“I don’t know of anyone but us who has an extensive gearbox exchange pool. Some owners have spares, but they usually are not well maintained,” he said. “Gearboxes need to be properly maintained to prevent dust and moisture from entering the assembly. That’s why our 43,000-square-foot facility is clean and climate-controlled with segregated clean and dirty areas. We keep a stock of load-tested wind turbine gearboxes and mainshaft assemblies ready to go in our GBXchange to eliminate downtime.”

The 43,000-square-foot facility offers 40- to 50-ton lifting capacity along with offices, a training center for technicians and customers, and a 3.1-MW regenerative test stand, which was designed to test a variety of gearboxes with real-life variable conditions. The lobby is dedicated to different failure modes, offering a visual message to visitors that this business is all about gears.

Each gearbox is inspected and tested to stringent standards to ensure customers obtain the maximum life from each gearbox that leaves the Wisconsin plant.

The custom-designed test stand allows for varying torque throughout the test to induce spike loads to more accurately simulate the operating conditions within a Turbine.

“With the design of our test stand, we are able to far more accurately replicate the conditions that a gearbox may see compared to using a traditional load test stand,” he said.

Providing gearboxes for the wind industry is different from providing remanufactured gearboxes to other industries, according to Neumiller, who says wind gearboxes have much tighter tolerances and higher quality standards.

“Using original equipment gearing when possible, along with our sophisticated test stand is the reason the three year warranty we offer is possible. It’s unique in the industry,” he said. “With traditional rebuilds, many people are using reverse-engineered gears. If you aren’t aware of the heat treat tolerances or material specifications, then you don’t know how a gear will operate so you may have premature component failure,” he said.

“By using original equipment when possible, every component we replace in the gearbox is done to OEM specifications which gives our customers a better product in the end,” he said. “We make a variety of upgrades to gearboxes to address infant mortality. We install coated bearings to alleviate cracking and we also address filters and water removal systems. We take what’s already a good product and make it better.”

“Turbines are just now starting to come out of warranty,” he said. “We have entered a specialized niche as the only truly independent, high quality, third-party remanufacturer of gearboxes in the United States. That was by design. We are entering an area where many people don’t yet know they need our services,” he said. “As the industry reaches maturity, there will be a rude awakening as to the volume of gearboxes that will fail. We are ready for that day.”

For more information:

Call 262-378-4303 or go to www.gearboxexpress.com.