The development of a successful wind-farm project depends on the developers’ knowledge of how much energy can be produced in the potential development area. Location-specific information regarding the wind speed, meteorological patterns, terrain, and other factors advise the siting and design of a new wind-power project. But as turbines grow taller, it is important to accurately collect valuable wind data at the heights necessary to minimize uncertainty and ensure bankability.

In the past, meteorological masts served as the primary measurement technology for wind applications, but these instruments are struggling to keep pace with wind-energy innovation. Enter Lidar as a viable tool for accurately measuring the wind for even the tallest turbines, onshore and offshore and across a variety of climates and terrain types.

Gathering the Right Data with the Right Tools

Wind resource assessment (WRA) is a crucial stage in wind-energy development. The make-or-break point for any onshore or offshore wind farm project, WRA is imperative to collecting accurate data before construction can begin and is essential for securing financial investment.

While it is obvious that wind farms work most efficiently in locations with the most substantial wind-power generation potential, knowing where and how to optimize a site is paramount to production. Predicting how much power will be produced by atmospheric conditions at a given site, however, is only possible with the correct measurements. Since each wind farm is unique and presents distinct challenges, accurately quantifying the wind resources at a given site is critical to determining its financial and practical viability.

A met mast has been traditionally installed when measuring the behavior of the wind at a particular site because it creates a trackable data set, which can help investors feel more at ease when deciding if a project is worth funding. Even though met masts are typically reliable, their height makes them dangerous to work on.

Complicating the issue further, these free-standing towers equipped with meteorological instruments are prone to mechanical error because of extreme weather conditions and vandalism. Finding and waiting on replacement parts can be difficult enough for wind-energy decision-makers, but global supply chain issues brought on by the pandemic have exacerbated these problems, causing repair times to skyrocket.

There are also limitations to a met mast’s ability to effectively gather data at the hub heights of modern turbines. Shorter met masts rely on vertical extrapolation techniques that typically introduce error and uncertainty.

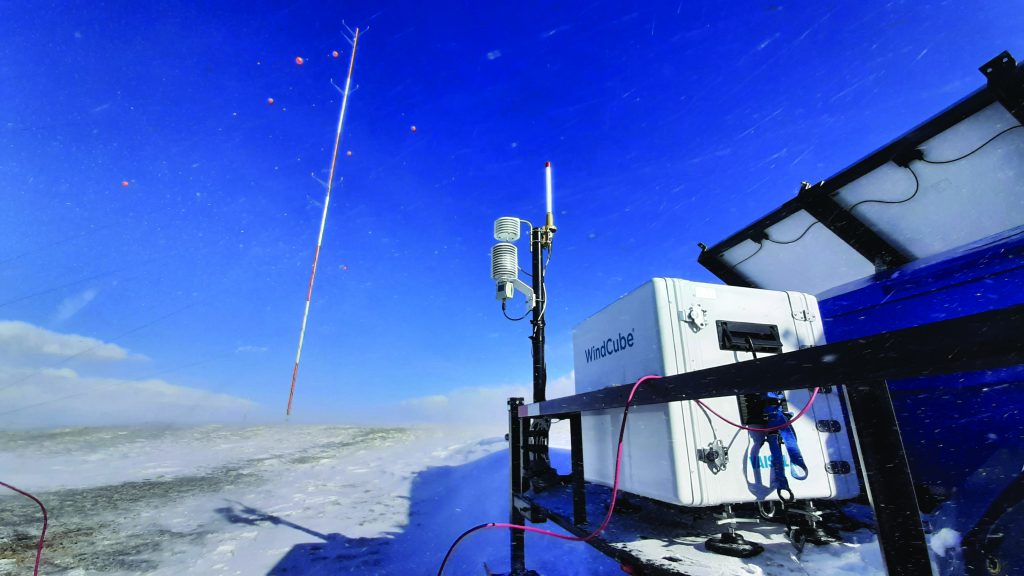

Additionally, installing a met tower is expensive and requires significant time and a lengthy permitting process. For offshore wind development, using met masts is impractical due to the construction requirement of a multimillion-dollar foundation out in the ocean. However, innovations have allowed companies to collect data about wind sites safely, quickly, and at unprecedented heights using Lidars, like Vaisala’s WindCube.

It is no wonder that Lidars have almost completely replaced the met mast offshore. In fact, IEA Task 52, also called the “wind Lidar” task, expects Lidar technology to fully supplant traditional met masts, with Lidar already accounting for at least 10 percent of onshore WRA campaigns and permanent wind monitoring.

The Next Step Forward in WRA Data Collection

In an industry where massive wind farms spring up regularly, light detection and ranging (aka Lidar) sensors can give developers an edge over their competition.

Lidar measures wind speed and wind direction by illuminating pulsed laser light and measuring the time for the reflected light to return. This advancing technology is changing how we map and measure the world and is increasingly used for hazard assessment, river surveys, atmospheric studies, wind profiling, and many other applications.

As the capacity and development of wind energy continue to increase, Lidar is quickly gaining in popularity among wind-energy industry stakeholders as a more cost-effective and accurate means for measuring wind output at every stage of a wind-farm project, whether it’s a WRA campaign, power performance testing, turbine prototype testing, or permanent wind monitoring.

With wind data collected by Lidar at multiple user-defined heights, wind developers can more accurately assess wind resources at a given site and decrease uncertainties in the annual energy production (AEP) calculations. Not only does Lidar technology allow developers to more accurately assess the success of their projects at an early stage, but it also streamlines regulatory approval, as regulators can access more accurate information about the project.

Recent research and real-world deployments reveal a WRA based on a standalone Lidar has almost the same uncertainty as one based on a hub height wind measurement with a met mast. Several Lidar types can be used for wind measurements. In offshore, vertical profiling and scanning Lidars can either be mounted on existing offshore platforms or placed onshore at the coastline. Lidar can also be integrated into a floating Lidar system (FLS), increasingly leveraged for offshore wind-measurement campaigns.

In onshore, several vertical profilers can be used in a measurement campaign: one as a fixed point of measurement while the others are moved around the site to decrease horizontal measurement uncertainty. By providing both the spatial resolution to analyze bigger areas and direct wind assessment to reduce vertical uncertainty, scanning and vertical profiling Lidar equipment decreases uncertainty and improves project bankability.

The advantage of using Lidar over more traditional technology is that it provides detailed measurements of the wind field at multiple heights above the ground, which can help determine wind speed and direction over large areas and deliver crucial environmental data quickly and safely.

In addition to the more accurate measurements at various heights, Lidar also delivers advantages such as speed and ease of deployment, flexibility, mobility, and reusability. At the same time, WindCube Lidars have been continuously validated and verified by independent third-party consultants to ensure data accuracy and project bankability.

These advantages over met masts help ensure the technology can be used across many types of terrain and in all climates. To better account for sitewide spatial variation and reduce wind-flow modeling uncertainty in complex terrain, modeling technologies exist to account for nonhomogeneous wind flow, correcting Lidar data so it is accurate, reliable, and bankable.

These advantages are increasing confidence and acceptability, motivating the trend away from met masts and toward Lidar as a standalone measurement system for WRA and the ensuing stages of a wind-energy project. Lidar is becoming standard for WRA, and the technology is only improving as the wind-energy industry seeks increased data accuracy, reliability, and safety measures beyond traditional met masts.

With Lidar, the Future is Now

As wind-energy generation costs continue to fall, its potential for contributing to a country’s electricity production is only becoming more relevant. This renewable resource is often challenging to assess because wind varies in time and space, resulting in complex measurements required for efficient operations. New technological strides are making this process easier and more fine-tuned, increasing investor confidence in the wind-energy industry.

As wind-energy developments continue, the demand for Lidar in WRA will also increase. At the same time, significant technological advancements are improving efficiencies and making Lidar a more viable option for projects of all scales. If you’re in the wind-energy industry, you’ll want to use Lidar, period. No other technology comes close to delivering the same kind of actionable wind energy information across each development project stage as lidar.

Today, the wind-energy industry has the necessary guidelines and standards that create global confidence, knowledge sharing, and standardization of Lidar as an essential and expected part of most standard wind-energy processes. As Lidar technology advances and the wind-energy industry continues progressing into an increasingly tech-driven space, decision makers can expect that, within the next two decades, met towers will be replaced by Lidars to a large extent — if not exchanged entirely — for wind measurements in the wind industry.

When your entire project depends on the initial wind resource assessment, gaining the complete picture of the wind’s behavior at a given location is only possible with modern Lidar solutions.

About the author

Elvira Aliverdieva is a product and marketing specialist at Vaisala, a global leader in weather, environmental and industrial measurements specializing in the evolution of the company’s onshore and offshore wind-product strategy with a primary focus on the booming offshore market.