Wind energy is a sustainable, safe, and impactful way to combat climate change and protect the future of the planet. However, most of the wind-turbine market is either involved in selling small (less than 150 kW power) or very large (greater than 1.5 MW). The small turbines are used in distributed energy on farms or small companies. The larger wind turbines are used almost entirely in large wind-farm operations with more than 50 wind turbines. There is a rising need for midsized wind turbines in distributed energy applications with data centers being the most talked about now.

What this article is focused on is encouraging and bringing awareness to the very small practice of installing midsized rebuilt wind turbines in these many potential distributed energy applications. The current U.S. federal tax code and the much lower cost of rebuilding and reusing midsized, decommissioned wind turbines provides for a very rapid return on investment using these tax incentives (there are even cash payment options to not-for-profits by the IRS in lieu of tax credits) and rebuilt midscale wind turbines. So, instead of buying power from a big utility company or an anonymous mega wind farm (and paying transmission and distribution charges), why not invest in rebuilt modernized wind turbines and enjoy both the economic and social marketing benefits of having an onsite refurbished wind turbine(s) producing much of the needed electricity with wind turbines that take very little space on the property?

Relying on a turbine’s strengths

The U.S. is reaching a critical juncture for increasing electricity, reducing fossil-fuel consumption, and doing so in a way that maximizes green energy production to reduce climate change and doing so economically — and do this with U.S. workers and small companies. Use of wind turbines in distributed energy application needs to be a big part of that due to the wind turbine’s ability to produce power locally — reducing reliance on grid delivery of power to users — on a year-round basis (which solar is not well suited for in the northern portion of the U.S.). The question becomes: where to acquire the mid-sized wind turbines that work well in behind-the-meter applications, yet produce between 500 kW and 1 MW of power, which is what most commercial and industrial users need, and it’s especially needed to support the huge projected increase in data-center construction and use. Recycling, modernizing, and reusing older wind turbines being decommissioned because of repowering has been used in Europe for years and needs to be done in the U.S. to satisfy this market need.

The Distributed Wind Energy Futures Study, released in May 2022 by NREL, determined substantial economic potential for distributed wind (defined as a project with a positive rate of return). The 2022 baseline scenario economic potential was 919 GW (equal to 919,000 1MW wind turbines) for behind-the-meter installations and 474 GW for front-of-the-meter installations (McCabe et al. 2022). So, there is a huge economically viable need for distributed wind energy.

The U.S. has 73,000 utility scale wind turbines, representing almost 3 trillion tons of steel and fiberglass that will be scrapped, without this recycling /reuse life extension technology. In the worst case of zero percent recycling and 100 percent landfill of fiberglass, greenhouse gas (“GHG”) emissions would increase by 2.8 trillion kg CO2, which would need to be removed by new turbines. Recycling even half of the 70,000 wind turbines in the U.S. would clearly lead to more than a 50 percent drop in steel and fiberglass scrapping and avoid the huge use of energy to create replacement wind turbines.

Additionally, gearboxes, generators, and other drivetrain parts are badly needed for spares, so that means almost another 50 percent of decommissioned turbine drivetrains can be rebuilt, which would further increase recycled rare-earth elements by reusing decommissioned drivetrains. In addition, as fiberglass blades of the size used in these decommissioned wind turbines are not being made anymore, even with the turbines not entirely being recycled, the salvaging of the blades to be available as spares would further reduce the scrap blade problems. Recycling and reuse of wind turbines has been shown by Rockwind to provide much better pricing (about 50 percent of the purchase cost of new turbines — if they can be found) for mid-sized wind turbines compared to new similar-sized turbines, and as technology develops, even the larger wind turbines will be available for reuse.

Refurbishing turbines

Rockwind has perfected this technology over the past 10 years by refurbishing older decommissioned wind turbines and reusing them in distributed energy applications. Rockwind has accomplished this for three mid-sized wind turbines in the Midwest (see Figures 1 and 2) using an existing supply chain of smaller Midwest manufacturing and construction related companies. In evaluating the major suppliers of on-site distributed wind installations in the U.S. in recent years, almost all of them have used new wind turbines imported from China or Europe. Unfortunately, many of those turbine suppliers have gone out of business or simply don’t make mid-sized wind turbines that are most readily used in onsite locations, as the current crop of turbines are way too big to get community approval due their size (with heights as tall as 30- to 60-story buildings) which can overwhelm the neighborhood landscape. The use of mid-sized rebuilt wind turbines solves three major problems in onsite distributed energy:

- It provides high quality turbines of a size that fits with community size scale.

- It allows them to be purchased at a price that provides rapid payback.

- Turbines can provide much more annual power than new small (less than 200 kW) wind turbines, which are inadequate to fulfill the typical daily power needs of businesses, data centers, truck stops, schools, etc. These small turbines, to their credit, are largely made in the U.S.

Following Europe’s example

For 20 years, Europe has encouraged the reuse of entire wind turbines (minus foundation) by taking the decommissioned turbines down carefully, and refurbishing and reselling them to developing countries. Europe has done this to keep wind turbines out of the waste stream. European rules forbid the disposal of used wind turbines in landfills and are implementing rules to forbid most of the nacelle components from being destructively disposed. This is not being done in the United States; as in current practice, wind turbines are now required by owners to be torn down and scrapped.

As to the stock of rebuildable wind turbines, the DOE distributed wind-turbine database shows that in the U.S., there are more than 2,000 turbines of less than the 1,000 kW size installed, which are likely to be scrapped in the next few years, with thousands more of the 1-plus MW size now beginning to be repowered and destroyed in the next 10 years. There is also a major cost savings in refurbishing U.S. wind turbines, as shipping European wind turbines to the U.S. adds $250,000-plus in shipping costs. Finally, U.S. electricity runs on 60 Hz service, as is true for most of the Western hemisphere. European electricity runs at 50 Hz, meaning there is a significant extra cost of converting 50 Hz wind turbines to 60 Hz operation. This means that rebuilt U.S. 60 Hz wind turbines have that extra value all over the Western Hemisphere.

Business benefit to the wind turbine purchaser

Under current IRS rules, these rebuilt wind turbines will qualify for investment tax credits (ITC) for the purchaser for as much as 60 percent of the purchase price, including installation, making these rebuilt wind turbines a very good value. These rules are set to last until at least 2032. So, as a reminder to owners of less than 1-MW wind turbines, that old turbine sitting there has a value to rebuilders of more than the cost of taking the wind turbine down (decommissioning ) and cleaning up the site — which then can be used to install bigger new or used rebuilt wind turbines to keep the income stream going for another 20 to 30 years, with minimal disruption or damage to property. Also, the reuse and careful documentation of that should allow a restart of a new batch of ITCs using fewer new replacement machines. The DOE database indicates that hundreds of these smaller older wind turbines are being used in small wind farms with less than 10 wind turbines, which are now likely to be 30 years old or more, but rebuilders can remove these smaller quantities of older wind turbines cost effectively, which means the small operators can repower at less net new costs. Larger turbines, of course, can also be decommissioned, rebuilt, and resold and even sold in small numbers to the small operators at excellent installed costs.

Positive results

Rockwind has demonstrated this recycling/reuse strategy by rebuilding and modernizing (using an extensive supply chain of existing U.S.-based wind turbine spare parts builders) midsized wind turbines used in distributed energy applications, with less than 10-year payback. Rockwind has rebuilt these midsize wind turbines (two 600 kW and one 250 kW machines) using the latest aerospace technology. One 600 kW turbine has been running for 11 years at the Method Soap factory in Pullman, Illinois; the other 600 kW unit has been running now for more than four years at an Aldi Distribution Center (producing over 2.2 GW/h of power to date). And the rebuilding and installation was done in the U.S. using well-paid U.S. labor.

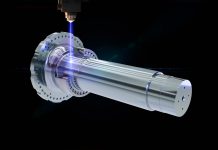

This market requires very high-quality rebuilt wind turbines. It is much cheaper to rebuild wind-turbine components on the ground than in the air and by offering customers two-year warranties, it requires the turbines be perfect. Gearboxes are rebuilt in the U.S. using newer technologies such as “superfinishing” and the highest quality materials. Generators are similarly rebuilt by U.S. subcontractors who specialize in rebuilding wind-turbine generators, and these generators are thoroughly tested.

Turbine SCADA controls are updated to the latest solid state controller technology including condition monitoring systems, where possible. Turbines have for 30 years been capable of being run remotely, but using newer, smarter controls, which can manage a wider variety of operating conditions and events.

(As part of an experiment, a 600-kW wind turbine from the Falkland Islands was able to be controlled from more than 6,000 miles from the turbine location.) Communication is offered both via fiber optic cable into adjacent buildings and by 4G cellular service. Advanced technologies used in the rebuilding of these wind turbines are now commercially available (however, from only a few vendors in the supply chain) for parts rebuilding. These technologies were not used in older turbines, or in many cases, even in today’s new turbines, due to their higher first costs.