In the wind power industry, the sheer diversity in the design and size of wind turbines represents a challenge for the growing number of service companies offering maintenance and repair. Individual turbine power has increased as well as the number of wind turbine installations. Wind turbines are normally designed for an operational life of 20 years, but reality has shown that the survivability of major subsystems such as gearboxes falls short. This has brought a higher demand for service operations on gearboxes. Wind farm operators and utilities face the same challenge of how to maintain availability and reduce downtime, and especially when gearbox repairs are required on short notice.

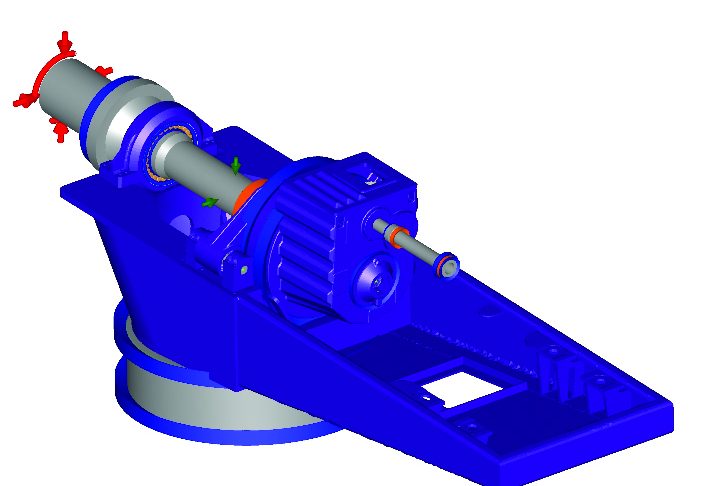

Kit Concept

Kits from SKF have the potential to make gearbox bearing replacement a more straightforward task for the most common gearboxes in use. Initially SKF has developed kits based on the most popular wind turbine gearbox types. The goal is to cover the majority of the common types on the market. The new bearing kits combine SKF’s strong industry knowledge with manufacturing capabilities and distribution expertise. SKF can determine the components needed for refurbishment and deliver a complete kit specific to different gearbox types.

For the service provider and the wind turbine operators, the kits offer a number of practical and potentially time- and cost-saving benefits. Since SKF holds the kits in stock, they can offer swift delivery from a dedicated source, which can help reduce downtime and lost productivity. Holding of a stock by the workshop is eliminated because the kits provide the requirements of each individual repair job so inventory and warehousing costs for the service company are significantly reduced. Having the bearings available as kits will make it easier for the wind farm owner or the service provider, avoiding the time spent searching and simplifying the sourcing of multiple parts. All this is supported by the worldwide availability of SKF distributors and a well-developed logistics network.

Solutions Required

Wind power is booming. In 2009 the world’s wind power capacity grew by almost a third, bringing total installations up to 157.9GW. Although that’s only 2 percent of the world’s total electrical energy generation capability, growth continues at a high level. This brings challenges not only from the perspectives of design, manufacture, and installation, but also from the perspective of the operational and maintenance requirements of an ever-larger asset base. All that machinery needs maintenance, particularly key components such as the gearbox. Repairs and refurbishment become ever more pressing issues as turbine systems become older through the years.

According to the publication Wind Energy—the Facts, produced under an EU-funded program, operation and maintenance costs for a new turbine may easily make up 20 to 25 percent of the total average cost per kWh produced over the lifetime of the turbine. While gearboxes have around a 10 percent annual chance of failure, the consequence of that failure can be disproportionately costly. The loss of productivity when the gearbox is in a workshop while waiting for spare parts can add up to thousands of dollars a month through reduced generation capacity. Bearing availability can be a problem, starting with getting to know which types of bearings are actually in the gearbox. SKF wind gearbox kits are designed to offer faster, easier maintenance when bearing replacement is required.”

SKF believes the kits will be especially helpful to the emerging third-party service industry supporting wind farm operations, concerning turbines in their post-warranty phase. Whether these service companies are associated with the original equipment makers or based in-house with the power-producing company itself or operating as independent companies, all share the goal of keeping the turbines up and running.

Expanding Services

SKF has focused on applying reliability-centered maintenance technology to wind turbines for many years and has extensive knowledge and experience in providing remote condition monitoring service, asset management service and spare parts management services. By providing wind farm operators and utilities with fast, single-source access to the right parts for the right application, SKF wind gearbox bearing kits simplify the process of identifying and ordering components. Available for rapid delivery for a range of gearboxes, the kits help wind farms reduce short-notice repair times and can also serve as a proactive maintenance upgrade to boost gearbox performance.