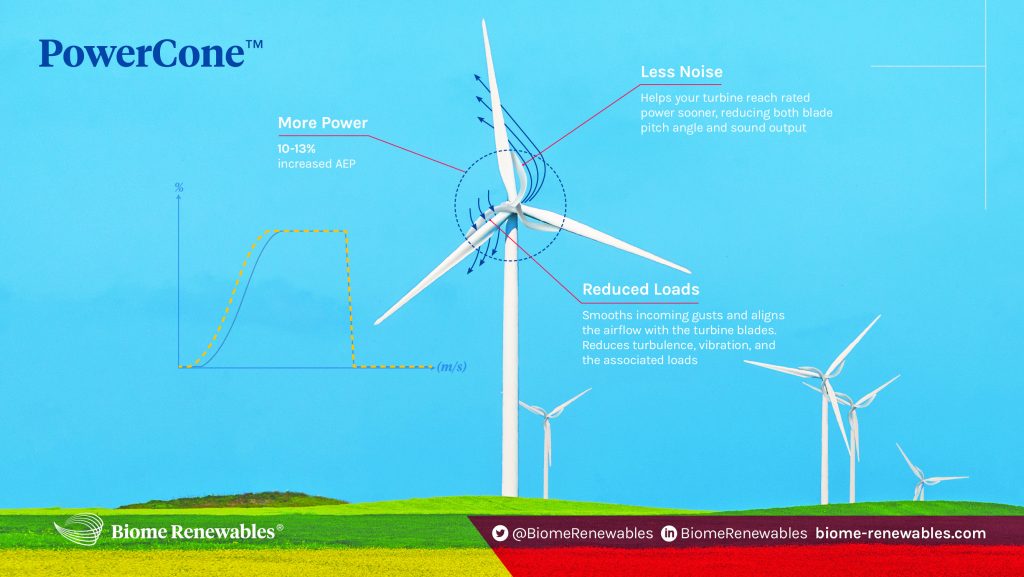

When it comes to the annual energy production (AEP) for a wind turbine, the industry says that gains of more than 1 to 2 percent aren’t possible. And that’s been the assumption for many years.

But the minds behind Biome Renewables say they have the means to increase that AEP by 10 to 13 percent with the company’s innovative PowerCone technology.

“We’re redefining the expectation for wind because that expectation, for a very, very long time, has been getting 1 to 2 percent more AEP; it’s been that way for decades now,” said Ryan Church, founder, CEO, and CTO of Biome Renewables. “So, for someone to come along and say, ‘I can do 10,’ that’s such a meaningful shift, and a lot of people are skeptical and rightly so. Because, every expectation is that 1 to 2 percent is the only thing that’s possible. And it’s really because no one is seeing and effectively tackling the biggest problem in wind.”

That problem, according to Church, is at the center the turbine.

“It’s really at the center where you can make the biggest impact,” he said. “It’s non-intuitive, but on a physics basis, it actually makes sense. I decided that’s where the innovations would start.”

Looking to nature

Biome’s central tenant is to look to nature for solutions to industrial challenges, and a serendipitous moment while watching a falling maple seed ended up being the virtual seed behind Church’s invention: the PowerCone.

“We have a family cabin up in BC, and there’s a maple tree next to the deck, and I saw a maple seed fall onto the deck,” Church said. “I’d seen maple seeds fall many times before that, of course, but for whatever reason, this time around it just seemed to be falling slower than I thought it should be.”

The aerodynamics of the maple seed caught Church’s attention.

“I ran a quick thought experiment in my mind, trying to ascertain what might be happening there aerodynamically,” he said. “I looked into it a bit and realized that’s a very efficient structure, and I actually went back to the problem of root leakage, which is an area of low pressure around the hub, and thought for a second: well, hang on, we can sort of use the principles of what the maple seed is doing and apply that to a PowerCone-like structure for the turbine.”

With that inspiration, Church built a crude wind tunnel in his living room to test various turbine configurations with structures made from plasticine and modeling clay and soon enough, sculpted a design that made meaningful gains.

“That was the first time that I realized that, hey, I might actually have something here, even at that crude level,” he said. “More research followed in the same kind of vein, and I filed a provisional patent.”

Knowing that he always wanted to start his own venture, Church understood that this was his opportunity, and seized the moment with this new biomimetic design.

Once the patent was filed, came investments, incorporation and a first wind-tunnel test at TU Delft, according to Church.

Positive feedback

The initial response to the PowerCone technology has been positive and encouraging, Church said, and that’s due to the statistical gains in performance that show up with the PowerCone.

“We want to see PowerCones on as many turbines globally as possible,” he said. “We want to help customers achieve the lowest cost of energy that they can, which may not be happening today, just due to maintenance issues and the fact that turbines are not operating as they should. That goes to the fact that, it’s not just power production, but it’s lifetime asset management. We’re giving the customer more power, but we’re also helping them on the loads front.”

“When you improve the aerodynamics, you also improve the loads,” he said. “They go a little bit hand-in-hand. Understanding the design-driving loads behind turbine design is very important to us, so we’ve learned a lot about that, leveraging partners like DNV.”

When the aerodynamics of a structure are improved, that means less drag, less flow separation, and less turbulence, according to Church.

Even though Biome launched in 2015, the technology that helped birth the company is definitely on the fast track, Church said.

“We have been getting multiple validation points of the technology working in different environments and at different scales,” he said. “Engineering a product of this scale is no simple feat. I mean, it has to be one of the largest R&D projects happening in wind in the last five or 10 years. It’s a huge undertaking that normally no private company outside of an OEM attempts. At least, I haven’t seen one. So, it’s an exciting thing to do to be blazing a trail of innovation and to be doing things that no one else has done before.”

Biome has received a number of awards, most recently named as one of the world’s top 100 clean-tech innovators from the World Energy Council.

It’s all about physics

To put it matter-of-factly, the industry would love to see a boost in AEP and wants it to happen, according to Church.

“We are excited about the customer reaction and industry reaction, and it makes us keep going and keep pushing,” he said. “The PowerCone does that on its own. It’s making a claim that has not been made before. It’s solving a problem that has not been solved before. From early research we really found that the wind industry was playing at the edges. Whereas, we’re coming in and seeing the problem and solving it.”

That speaks volumes as to how Biome approached this challenge, according to Church.

“At Biome, at least on the R&D and engineering side, we actually strip it back to the math and physics first,” he said. “You use the physics-first principle of looking at this problem.

And it started with Betz’s law — that’s a hundred-year-old theory, which started with a number of assumptions, some of which are no longer true. We peeled that back, and we looked at the physics that are actually happening, and we looked at how turbines have been designed today, and there’s a gap. And that gap is filled through innovation.”

That’s the thrust of what Biome does; the company relies heavily on design, engineering, and innovation.

Biomimicry: the core of design

“Biomimicry helps us innovate in ways that other companies just can’t or don’t,” he said. “It’s the multiple iteration loops that we go through — from talking to customers on the one hand and co-creating something with them, asking them what their problems are, and then on the other hand, we are looking at the math and the physics of it. And we’re pulling at it from multiple angles. And then nature comes in with the biomimicry piece, because nature is very good at solving problems.”

To that end, that’s what makes the wind industry and Biome such a good fit, according to Church.

“This is what the wind industry is; it’s fluid dynamics at the end of the day,” he said. “So, when you look at nature and fluids to get a sense of how nature would solve that problem, you start off with what is a near maximally efficient solution. That has to be changed and adapted, of course, to fit engineering requirements and different situations, but you’re starting off so much farther ahead than any company in the innovation chain, because you’re looking to nature pretty early on for clues of how to solve this huge problem. That is no easy feat, so the complexity keeps most other companies away. I think we’re unique globally, in that everything we design is biomimetic — even our corporate structure and business model is influenced by natural processes.”

Growing with the industry

With the wind industry growing by leaps and bounds, Church expects the PowerCone to help the industry grow even more than expectations.

“OEMs are making engineering leaps to make larger and larger blades and larger and larger towers for generators, but they’re not taking enough time and turbines are growing too quickly,” he said. “When that happens, down the line you end up with O&M issues.”

The PowerCone can help the industry grow in a more sustainable fashion, according to Church.

“You’ll be able to get the sort of normalized cost in energy drops that the industry is looking for without having to make a longer and longer blade,” he said. “Blade length determines just about everything. It kind of ripples through the whole engineering process of how you’d think about designing and building a turbine. All the different loads and all the characteristics of all the components, it all has a cascading effect. So, I think we can help the wind industry. We can help it grow obviously, but we can help it grow in a more sustainable way, and in a way that drops the levelized cost of energy both onshore and offshore. Both markets benefit from that.”