Although wind-turbine oil could last for 10 years or more, it can start degrading long before that. Given this and because oil is the lifeblood of turbines, regular testing is important.

While monthly oil analysis delivers a basic view of the oil’s condition, there are additional tests that should be performed annually to monitor key performance characteristics of the oil and help prevent unplanned downtime. Annual monitoring will assess physical and chemical properties and detect common contaminants such as water and solid particles.

This thorough analysis is also recommended for new oils that must meet rigorous performance specifications prior to selection and introduction.

TURBINE OIL — PURPOSE, COMPOSITION, PROPERTIES

Lubricating oil for wind turbines is specifically engineered to meet the demanding conditions of turbine gearboxes and bearings, especially in remote or harsh environments. These oils are typically composed of synthetic base oils, which exhibit superior stability, long service life, and the capacity to perform under extreme temperatures.

PURPOSE

The primary function of lubricating oil in wind turbines is to reduce friction and wear between moving parts, especially under high-load, variable-speed conditions. It also serves to dissipate heat generated during operation, prevent corrosion from environmental exposure, and keep internal components clean by suspending contaminants and preventing sludge or varnish formation.

Oils for use in wind turbines are formulated to support long service intervals, which is critical for minimizing maintenance. The goal is to ensure long-term protection, improve operational efficiency, and extend the lifespan of vital components in some of the most challenging environments.

COMPOSITION

To enhance their performance, the (usually synthetic) base oils are combined with additive packages that include anti-wear agents, extreme pressure additives, oxidation and corrosion inhibitors, foam suppressants, demulsifiers to separate water, and viscosity index improvers to stabilize viscosity across a range of temperatures.

PROPERTIES

The properties of wind turbine lubricating oils are specifically formulated to meet the operational demands of the equipment. These oils must have a high load-carrying capacity to manage the heavy torque and shock loads typical in wind-turbine gearboxes. They need excellent oxidation stability to enable long service intervals. The oil must also perform across a wide temperature range, particularly in cold climates where turbines are exposed to subzero conditions. Additionally, the oil should have a low tendency to foam, be resistant to water contamination, and maintain viscosity under mechanical stress. It also needs to be compatible with seals and materials within the turbine.

WHY AN ANNUAL TURBINE ANALYSIS?

The annual analysis is essential for maintaining equipment reliability, controlling costs and ensuring safety. One of the primary benefits is the early detection of wear and damage. By identifying metal wear particles in the oil, maintenance teams can catch developing issues in gearboxes, bearings, and other internal components before they escalate into major, costly downtime.

Regular oil analysis also helps monitor the condition of the lubricant itself. Over time, oil degrades due to oxidation, thermal stress, and contamination. Analysis reveals changes in key properties that directly impact lubricant performance. This is especially important for wind turbines exposed to extreme weather conditions. Oil testing can identify resulting contaminants, prompting corrective actions such as filtration or oil replacement.

Annual oil analysis also tracks long-term trends. In addition to establishing a maintenance record, it demonstrates compliance with environmental standards and warranty requirements [1]. An annual oil analysis is a powerful tool for protecting wind-turbine assets, optimizing performance, and supporting sustainable, cost-effective operations.

TYPICAL ANNUAL TURBINE ANALYSIS TEST SLATE

The standard test slate for an annual turbine oil analysis will vary slightly among labs; however, the following tests and methods should be included in an annual turbine analysis:

- Acid Number; ASTM D974: Acid Number (AN) is an indicator of oil serviceability. It is useful in monitoring acid buildup in oils due to depletion of antioxidants. Oil oxidation causes acidic byproducts to form. High acid levels can indicate excessive oil oxidation or depletion of the oil additives and can lead to corrosion of the internal components. By monitoring the acid level, the oil can be changed before any damage occurs.

- Color; ASTM D1500: The ASTM D 1500 color scale is used for contamination monitoring. If the fluid’s color is off specification, this can indicate contamination.

- Demulsibility; ASTM D1401: Demulsibility measures an oil’s ability to release water. Water shedding characteristics are important to lube oil systems that have potential to have direct contact with water. Demulsibility can be compromised by excessive water contamination or the presence of polar contaminants and impurities.

- Foam; ASTM D892: The tendency of oils to foam can be a serious problem in systems such as high-speed gearing, high-volume pumping, and splash lubrication. Inadequate lubrication, cavitation, and loss of lubricant due to overflow can lead to mechanical failure.

- FTIR; JOAP method: Every compound has a unique infrared signature. FTIR spectroscopy monitors key signature points of a specific lubricant in the spectrum. These signatures are usually common contaminants and degradation byproducts unique for a particular lubricant. Molecular analysis of lubricants and hydraulic fluids by FTIR spectroscopy produces direct information on molecular species of interest, including additives, fluid breakdown products, and external contamination. It compares infrared spectra of used oil to a baseline spectrum.

- Karl Fischer Water; ASTM D 6304 procedure C: Low levels of water (0.5%) are typically the result of condensation. Higher levels can indicate a source of water ingress. Water can enter a system through seals, breathers, hatches, and fill caps. Internal leaks from heat exchangers and water jackets are other potential sources. When free water (non-emulsified) is present in oil, it poses a serious threat to the equipment. Water is a very poor lubricant and promotes rust and corrosion in the components. Water in any form will cause accelerated wear, increased friction, and high operating temperatures. Non-emulsified water poses a serious threat to the equipment, leading to rust and corrosion. Emulsified water will promote oil oxidation and reduce its load-handling ability.

- Membrane Patch Colorimetry; ASTM D7843: The Membrane Patch Colorimetry test is used to measure the color bodies of insoluble contaminants in lubricants. By monitoring the level of insolubles present in the lube oil, informed decisions can be made regarding the implementation of varnish mitigation technology.

- Particle Count; ISO 4406: Using the Pore Blockage method, the sample is passed through a calibrated screen. As particles collect on the screen, the amount of flow decreases. This decrease in flow is measured, and the particle count result is obtained. Higher levels of particulates in the sample may indicate machine health issues, a high rate of external particulate ingression, or filter inefficiency. High levels of particulates can lead to accelerated machine wear due to abrasive conditions. Maintaining lower levels of particulates can increase the operational life of lubricated equipment.

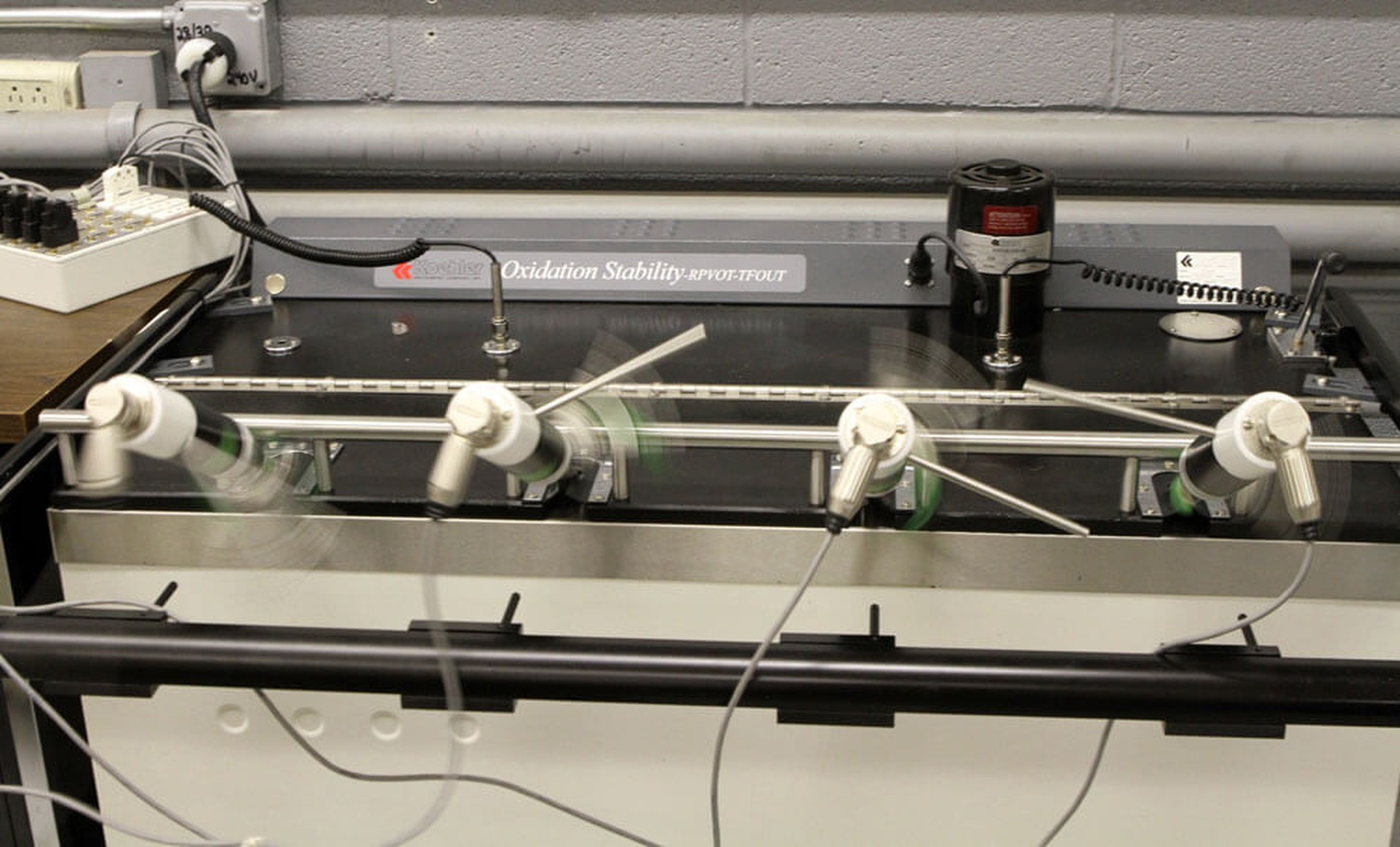

- Rotating Pressure Oxidation; ASTM D2272: The Rotating Pressure Vessel Oxidation Test (RPVOT) determines the oxidation stability of an oil by measuring the actual resistance to oil oxidation; whereas the other tests detect oxidation already present in the oil. Oxidation is a critical mode of lubricant degradation. As oil oxidizes, it forms acids and insoluble oxidation products, which can lead to formation of sludge or varnish. These degradation products can coat bearing and oil cooler surfaces, preventing adequate cooling of the bearings. Areas with tight tolerances such as hydraulic control valves can also become coated causing operational issues.

- Ruler; ASTM D6971: Linear sweep voltammetry, more commonly referred to as the Remaining Useful Life Evaluation Routine (RULER) test, measures hindered phenolic and aromatic amine antioxidant content. This test quantitatively analyzes the relative concentrations of antioxidants in new and used oils in order to monitor the depletion rate of the antioxidant protection package. Hindered phenols and aromatic amines are primary antioxidants used in many zinc-free turbine oil applications. By measuring the depletion and available reactivity of these antioxidant compounds while conducting other routine performance tests, the service life of used lubricants can be effectively monitored to determine remaining useful life.

- Rust A; ASTM D665 procedure A: The Rust Preventing Characteristics Test (ASTM D665) is designed to measure the ability of industrial oils to prevent rusting under conditions of water contamination. The test can be performed with either distilled water or synthetic seawater. The test consists of stirring a mixture of 300 milliliters of the oil being tested with 30 milliliters of water, either distilled or sea water, at 140°F (60°C) for four hours. A special cylindrical steel test specimen made of #1018 cold-finished carbon steel is polished and then completely immersed in the test fluid. At the end of the four-hour test period, the specimen is removed, washed with solvent, and rated for rust. A lubricant’s ability to prevent rust is crucial for systems, such as wind turbines, which have significant risk of water contamination.

- Spectroscopic Analysis; ASTM D5185: The Elemental Spectroscopy test uses a spectrometer to measure the levels of specific chemical elements present in an oil. Monitoring the concentration of metallic elements can provide important information regarding machine and lubricant condition. By monitoring wear metals such as iron, copper, tin, and lead, the rate of wear can be observed and abnormal wear modes can be detected.

Many contaminants have metallic components that can be monitored as well. Increases in contaminant metals such as silicon, aluminum, and potassium can indicate ingression of dirt, coolant, or process contaminants. Some additives also have metallic components. Monitoring additive metals can help indicate when a system has been topped off with the incorrect lubricant.

- Viscosity; ASTM D445: The single most important property of a lubricant is its viscosity. It is the measure of the oil’s resistance to flow (shear stress) under certain conditions. It is an important criterion in the selection of a fluid. At low temperature, excessive viscosity may result in poor mechanical efficiency, difficulty in starting, and wear.

As oil temperature increases, viscosity decreases, resulting in lower volumetric efficiency, overheating, and wear. Selection of the optimum fluid viscosity grade will provide the most efficient turbine performance at standard operating temperatures.

Critical indicators commonly uncovered during an annual turbine analysis include a failing foam test, a failing demulsibility test, low RPVOT, and high-varnish potential. The resulting report should be a complete rundown of each of the tests performed, along with a detailed explanation of each test result. The report should also contain a summary of findings, as well as recommended actions specified by analysts [2].

Inherent in the wind industry are distinct fluid challenges that ultimately decide the operational reliability of turbines. Maintenance requires lab expertise to determine the condition of the turbine’s fluid and overall health. No turbine can perform optimally with degraded oil. With regular testing, that’s one issue off everyone’s plate.

References

- Some turbine manufacturers and insurers mandate regular oil testing.

- Monthly oil analysis may also be recommended. It delivers a basic view of the oil’s condition. The test slate might include Acid Number, Spectroscopic Analysis, Fourier Transform Infrared Spectroscopy (FTIR), Viscosity, Particle Count and Karl Fischer Water.