Failures in wind-turbine main shaft assemblies (MSA) are an increasing concern in the industry, both for their frequency and the downtime they cause [1, 2]. The rising power density of turbines, driven by competitiveness, has led to higher MSA failure rates and the appearance of defect types not seen in smaller units. This trend is prompting a reconsideration of MSA design and calculation methodologies [3, 4].

Conventional repairs that restore MSAs to their original design may not be sufficient to extend service life. Surface coating techniques, increasingly applied in recent years, offer a viable alternative by enabling shaft restoration and avoiding scrapping. Compared with full shaft replacement, these methods can provide cost savings and shorter lead times, while also creating opportunities to improve shaft performance and reduce MSA failure rates.

Main Shaft Failures and Repair Strategies

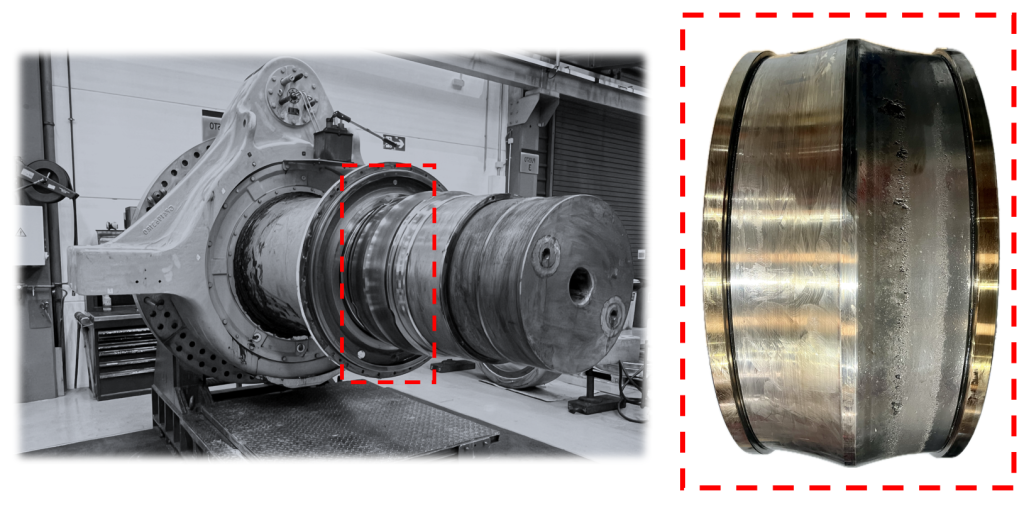

Wind-turbine main shaft failures (MSA) are increasingly common. Causes include inadequate bearing design, manufacturing or assembly issues, insufficient maintenance, shaft cracking [5], or current-induced failures [6]. Low rotational speeds complicate early detection through standard temperature or vibration monitoring [7]. See Figure 1.

Repair strategies often focus on selecting a replacement bearing — ideally with greater capacity than the original — to reduce the failure rate of repaired units [8]. Equally critical is ensuring the integrity of the shaft and housing so that bearings perform correctly.

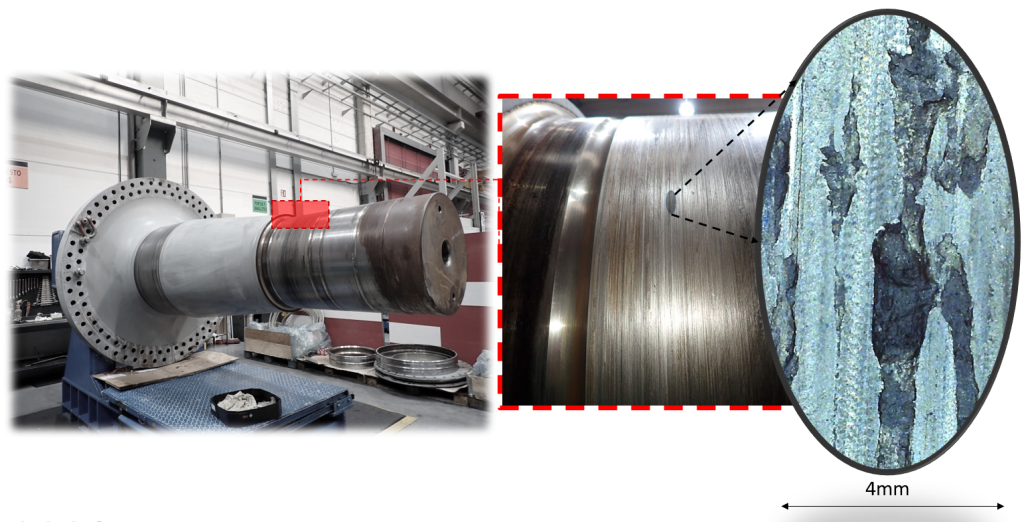

A recurring issue in MSAs is fretting wear on the bearing seat, caused by the hardness mismatch between bearing and shaft (≈60 HRC vs. <35 HRC). Fretting is localized surface wear caused by micromotions under load, directly affecting bearing performance and potentially initiating cracks in the shaft (Figure 2).

Reusing shafts offers cost and lead time advantages in MSA repair. Restoration may involve dimensional recovery via additive processes (coatings), or the use of oversized bearings to compensate for wear-related material loss.

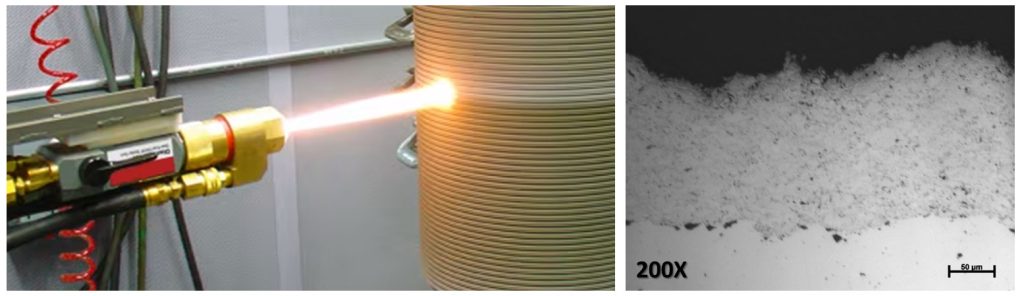

Although several additive techniques are available, their adoption remains debated. These processes are relatively unfamiliar, difficult to evaluate analytically, and sensitive to process control. Among the most widely applied and reliable methods are laser cladding and thermal spray (e.g., EAWS and HVOF).

This study presents laboratory tests comparing the wear and fatigue behavior of baseline shaft material with shafts recovered using laser cladding or thermal spray coatings.

Tribology Testing

Fretting wear is a primary degradation mechanism in shafts, driven by micromotions during operation and the hardness mismatch between shaft and bearing.

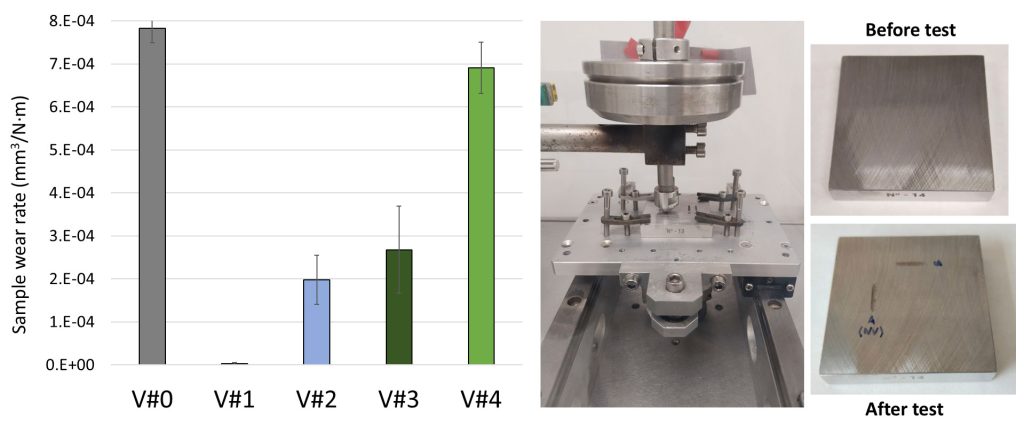

Wear tests followed ASTM G99 and included five groups of test samples (variants):

- V#0: Main shaft base material.

- V#1: HVOF.

- V#2: EAWS.

- V#3: AISI cladding.

- V#4: Inconel cladding.

The counterpart was a 6 mm diameter AISI 440C ball, with certified hardness consistent with bearing surface hardness.

Figure 4 summarizes the test setup and results.

Samples V#1, V#2, and V#3 showed significantly lower wear rates than the baseline (V#0). V#4 did not show meaningful improvement.

HVOF (V#1) delivered the best performance, with significantly the lowest wear rate of all variants.

Rotating Bending Fatigue Testing

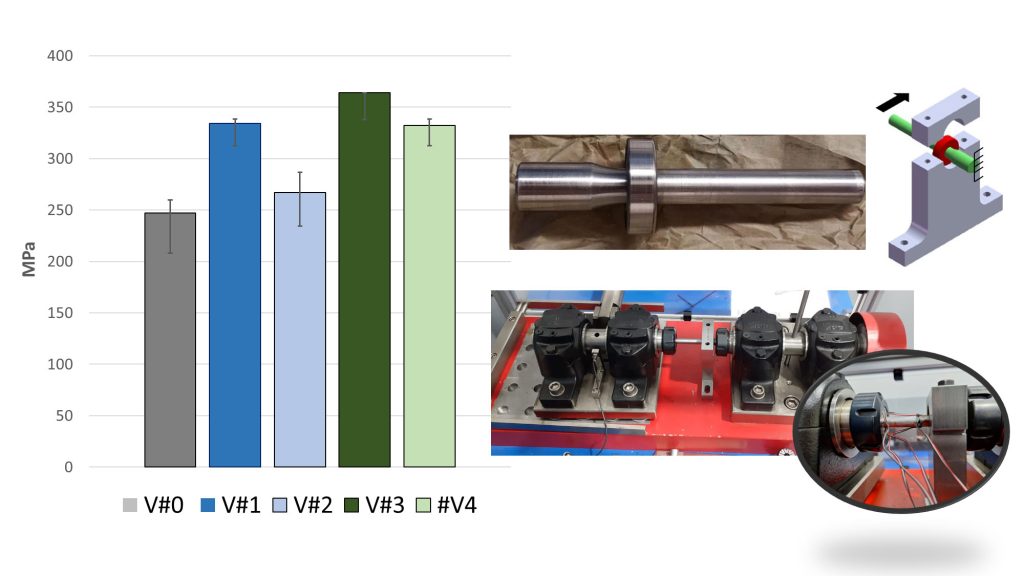

This test compared fatigue performance of baseline shaft material against shafts recovered by laser or thermal spray coatings.

Standard ISO 1143 rotating bending fatigue tests were modified by adding an intermediate bearing support where the coating was applied, to better simulate MSA wind operating real conditions under the bearing shaft surface.

Figure 5 summarizes the test setup and results.

All coated specimens performed better than the baseline (V#0). Although these results may appear inconsistent with prior studies [9, 10], the difference lies in the modified test boundary conditions, designed to replicate real MSA operational conditions, and not just to evaluate the difference between baseline material and coated mechanical properties. The configuration of this test, including bearing support, allowed evaluation of the fatigue effect of coatings under realistic conditions, where the previously described improvement in wear resistance played a significant role in crack nucleation.

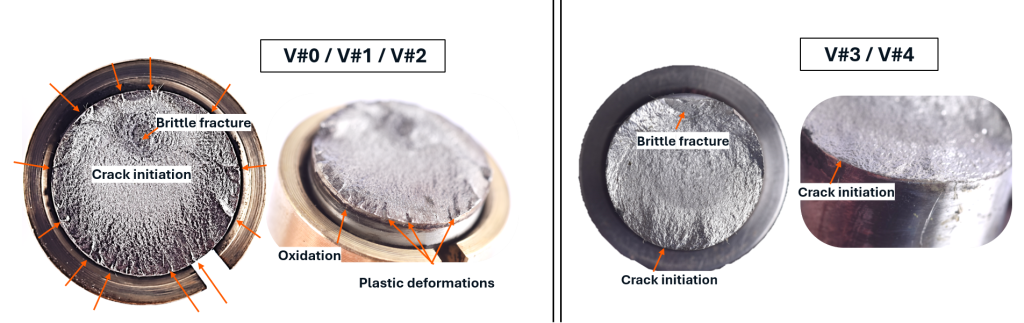

Failure morphology varies by coating type. In uncoated and thermal-spray-coated specimens (V#0, V#1, V#2), fractures originated at the surface. In contrast, in laser-cladded specimens (V#3, V#4), failures initiated below the surface within the heat-affected zone (Figure 6).

For uncoated specimens (V#0) and those with metal spray (V#1, V#2), fractures were located at the bearing interface. The origin was linked to fretting, with localized oxidation and plastic deformation generating oblique micro-cracks from which fatigue cracks propagated. These nucleation points appeared around the full specimen circumference. After nucleation, cracks propagated with smooth textures and beach marks, and the final rupture occurred through brittle overload, visible as a rough and shiny surface.

In laser-cladded specimens (V#3, V#4), fractures originated 2-4 mm beneath the surface, likely in the heat-affected zone. Crack initiation was concentrated in a region opposite the brittle overload fracture zone. Fatigue cracks then propagated until final brittle overload failure occurred.

Conclusions

Laboratory tests confirm that both thermal spray and laser cladding significantly improve wear and operational bending fatigue resistance compared to the baseline main shaft material.

These coating methods therefore offer strong potential to enhance the performance of (refurbished) main shafts, provided that additive process parameters are rigorously validated and controlled. Special attention must be given to risks such as adhesion failures in sprayed coatings or crack formation in the transition zones of laser cladding.

References

- Keller, Jonathan, Shawn Sheng, Yi Guo, Benjamin Gould, and Aaron Greco. 2021. Wind Turbine Drivetrain Reliability and Wind Plant Operations and Maintenance. Research and Development Opportunities. NREL/TP-5000-80195. https://nrel.gov/docs/fy21osti/80195.pdf.

- Hart, Edward, Kaiya Raby, Jonathan Keller, Shawn Sheng, Hui Long, James Carroll, James Brasseur, and Fraser Tough. 2023. Main Bearing Replacement and Damage − A Field Data on 15 Gigawatts of Wind Energy Capacity. NREL/TP-5000-86228. https://www.nrel.gov/docs/fy23osti/86228.pdf.

- Wind Turbine Main Bearing Reliability Analysis, Operations, and Maintenance Considerations. EPRI. https://www.epri.com/research/products/000000003002029874.

- Kenworthy J, Hart E, Stirling J, et al. Wind turbine main bearing rating lives as determined by IEC 61400-1 and ISO 281: A critical review and exploratory case study. Wind Energy. https://doi.org/10.1002/we.2883.

- Wang R, Han T, Wang W, Xue Y, Fu D. Fracture analysis and improvement of the main shaft of wind turbine based on finite element method. Advances in Mechanical Engineering. 2018. Doi: 10.1177/1687814018769003.

- Zhao, J., Xu, X., and Carlson, O.: Electrostatic discharge impacts on the main shaft bearings of wind turbines, Wind Energ. Sci., 8. https://doi.org/10.5194/wes-8-1809-2023.

- Jason Shapiro. Data-Driven Main Bearing Maintenance Strategies to Reduce Unplanned Maintenance Costs. WindSystems magazine, 2016. https://www.windsystemsmag.com/data-driven-main-bearing-maintenance-strategies-to-reduce-unplanned-maintenance-costs.

- Samuel M. Gbashi, Obafemi O. Olatunji, Paul A. Adedeji, Nkosinathi Madushele. From academic to industrial research: A comparative review of advances in rolling element bearings for wind turbine main shaft. Engineering Failure Analysis, 2024. https://doi.org/10.1016/j.engfailanal.2024.108510.

- Marcelino P Nascimento, Renato C Souza, Ivancy M Miguel, Walter L Pigatin, Herman J.C Voorwald. Effects of tungsten carbide thermal spray coating by HP/HVOF and hard chromium electroplating on AISI 4340 high strength steel. Surface and Coatings Technology, 2001. https://doi.org/10.1016/S0257-8972(00)01148-8.

- Halmi, M. A. M. and Harimon, M. A. and Tobi, L. Mohd and Mahmod, M. F., Fatigue Performance of Thermal Spray Coatings on Carbon Steel: A Review (September 13, 2019). International Journal of Mechanical Engineering and Technology. https://ssrn.com/abstract=3453020.