The power distribution grid is undergoing unprecedented levels of change. The traditional one-way model of voltage regulation presumed voltages dropping predictably along feeders from substation to customers.

However, the growth of distributed wind-energy systems is rendering traditional models and regulation techniques incapable of maintaining delivered voltages within ANSI C84.1 guidelines.

According to the U.S. Department of Energy’s Office of Energy Efficiency and Renewable Energy (EERE) website, (www.energy.gov/eere/wind/distributed-wind) the Wind Energy Technologies Office defines distributed wind in terms of technology application, based on a wind plant’s location relative to end-use and power distribution infrastructure, rather than technology or project size.

The growth potential of distributed wind-energy systems is enormous.

“An analysis of behind-the-meter distributed wind potential in the United States found that distributed wind systems are technically feasible for approximately 49.5 million residential, commercial, or industrial sites, or about 44 percent of all U.S. buildings,” the EERE website said.

This is spurring new approaches in grid measurement, monitoring, and control that provide real time measurements that enable distribution management applications to better manage voltages and maintain high power quality.

Voltage Fluctuation from Distributed Wind

Voltage Fluctuation from Distributed Wind

The traditional power delivery model pushes electricity from a centralized power generation plant through distribution feeders to the point of consumption. Power is consumed along the line with utilities using tap changers, voltage regulators, and capacitor banks to regulate voltage to ensure delivery remains within an ANSI guideline range of ±5 percent all the way to the end of the line. Historically, the key concern was ensuring voltages did not fall below or above these standards.

Enter distributed wind-energy systems. These are commonly installed on, but are not limited to, residential, agricultural, commercial, industrial, and community sites, and can range in size from a 5-kilowatt turbine at a home to multi-megawatt turbines at a manufacturing facility or connected to a local distribution system, according to the EERE website.

These points of power generation inject power along the distribution feeder, which may increase or decrease voltage levels outside ANSI guidelines. In other words, increasing integration of renewables means variable load and generation fluctuations that work against the constant voltage profile model.

In addition, distributed wind is, by nature, intermittent. Managing unpredictable intermittency without measurement, monitoring, and control is even more difficult and may result in oscillatory voltages in the system. Voltage rises at injection points may also create reverse systemic power flow.

As a result, utilities require more advanced power monitoring and control systems that can precisely and quickly measure voltage to enable their distribution management systems (DMS) to respond and regulate the voltage on their feeder lines. But this means DER integration needs real-time data to implement their control strategies.

“The issue goes beyond simply burnt toast in a home,” said Ray Wright, VP Product Management, Power Products at NovaTech. “What we are concerned about with unpredictable voltage delivery is the disruption of service to household, commercial, and industrial customers all along the feeder, including damage to motors and equipment and interruption of service.”

More Precise Monitoring and Control

The challenge of effectively controlling unpredictable, variable and potentially bi-directional voltage flow starts with measurement. The only way to control this kind of variability is to have measurements along distribution feeder lines that are accurate and that can communicate data to control systems fast enough to modulate the voltage and keep it under control — essentially in real-time.

Voltage delivery monitoring and control can be the domain of DMS. These systems have evolved over the years with advanced DMS models now in use that use volt/var optimization (VVO) where capacitor banks, voltage regulators, and solid-state systems are switched on and off to maintain acceptable levels of power factor and voltage. More recently, distributed energy resource management systems (DERMS) have emerged in response to the increasing amount of renewables-based distributed energy resources. These are complex control systems for monitoring and controlling sources of energy.

“DERMS requires accurate, real-time measurement of voltages, loads, reactive power, fault data, and even weather data,” Wright said. “A key consideration has been how to design and install these monitoring systems in a way that is cost-effective for utilities. This has called into question the traditional approach of grid monitoring with conventional magnetic current transformer (CT) and potential transformer (PT). The installed cost of CTs and PTs is expensive and time-consuming, plus the feeder must be powered down for their installation.”

An alternative lower-cost approach is to employ low voltage (0-10V AC) sensor technology for all voltage and current measurements. These sensors are safe, accurate for all required measurements, and can be installed without taking an outage.

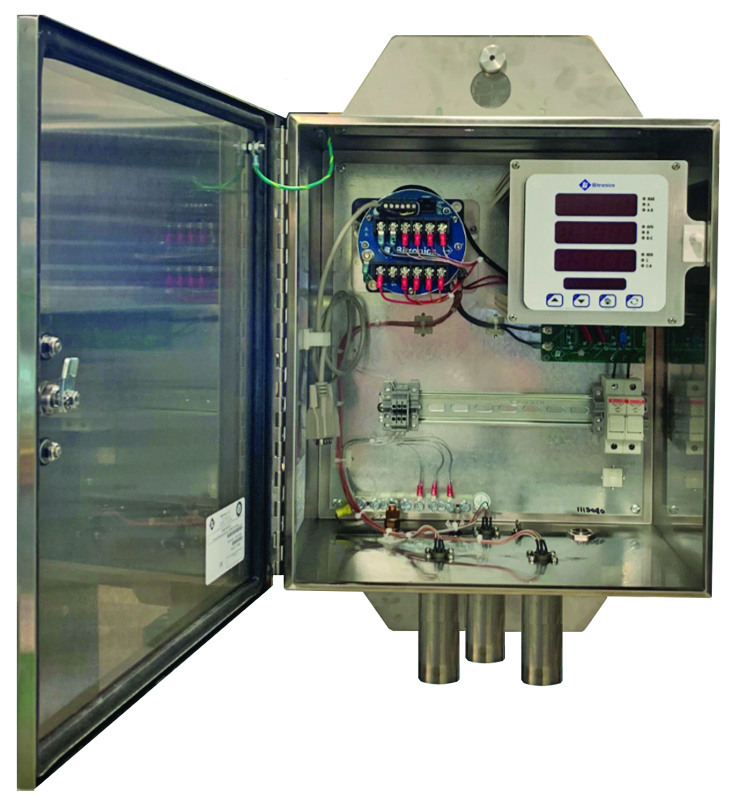

Three raw voltages and currents can be wired to a Bitronics distribution grid monitor (DGM), a pole-top measurement system, and dozens of useful measurements made including voltages to better than 0.5 percent, loads, power factor, real, and reactive power. An ANSI 51 overcurrent element enables reporting of fault pickup and peak fault currents. All these measurements are reported to DMS and DERMS through DNP3 over radio.

“Initial DGM deployment at a New England utility drove further DGM enhancements,” Wright said. “This includes new measurements for ‘normalized voltage’ to accommodate sensor readings instead of PTs and CTs, additional surge suppression, and ‘safety shields’ to prevent tampering of cable connectors. This major project was driven by a utility commission mandate to accurately measure and report end-of-line voltages.”

Given that the trends indicate distributed wind-energy system integration will increase significantly each year, so too will the need to maintain voltages, power factor, and frequency within desired limits. New grid measurement and monitoring technologies are essential to keep these factors under control.