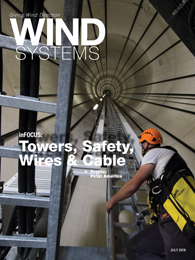

Safety plays a key role every day as a wind technician in the field, whether in the nacelle or on the ground. As turbines get taller and production starts to move offshore as well, what are the training aspects of safety that keep the technicians safe?

It starts with the interview process, where questions are asked to find out just how safety conscious you really are. Are you willing to put yourself in danger for the sake of the job? The clear answer is no. We want to instill a culture that safety comes first: Safety for ourselves and the safety of others. With a background as a site manager and EHS manager, I was involved with all aspects of site safety and certified in the conduction and reporting processes as OSHA began to set rules and regulations for the wind industry. But most turbine owners and manufacturers have set their own guidelines to surpass those being implemented by OSHA.

Range of training

The majority of wind companies and owners have implemented a wide range of safety training for the industry. Along with GWO (Global Wind Organisation), this training assures standardized climb and rescue training on an international scale. It also establishes protocols and contingency plans that are executed and exercised on a regular basic.

No technician is allowed to climb on site until he or she has been proven and certified by an instructor as a competent climber. Levels of training start from the basics of self-rescue and first aid to more advanced rescues. The more advanced rescues scenarios include evacuating an unconscious tech from a blade or pulling a person from beneath a gearbox.

At EcoTech, we use the same industry standards to train our students for these situations daily. This is where you want them to make the potential mistakes, not for the first time on the ladder in a real emergency. One-on-one instruction on the ladders gives the instructors the insight to each student’s level of proficiency and the time to refine their skills. Safety begins in the classroom and progresses as the students/technicians advance in their level of training and proficiency. Training daily in the processes of LOTO and extending the lessons with climb and rescue training, enhanced with different possible scenarios gives the feel of real life emergencies without the loss of life in the process.

As a technician, you can expect to use your knowledge of safety daily, with the numerous forms that are needed prior to starting your climb to the top, including JSAs, JHAs, PPE, Tailboards, etc. Only those properly trained for a procedure can perform said procedures. This protects man and machine alike, with personnel knowing how to respond in any unsafe situation. Upon course completion, students also receive their OSHA 30-hour card to present to their new employer showing they fully understand the hazards involved and how to mitigate them.

Safety 101

We teach the students Safety 101 from scratch, using industry standards and focusing on established safe practice methods. Students learn the proper use of LOTO identification and the energies we should safeguard against. With 3-phase 690-volt production, electrical energy is what we think of first when performing LOTO. But we teach them to look further into the process, such as what other types of energy we might need to safeguard ourselves against, including pressurized and stored energy, as well as gravitational forces that might come into play.

This also includes not only using the right tools for testing, but knowing you have the correct tool for the job. As the students’ progress through the courses, the level of safety training increases in its complexity. Ladder rescue and self-rescue training adds another element of real life to the exercises, and students compete on proficiency and time in the rescue scenarios. They learn team work most of all; being able to work with others is an important part of being a great technician.

In the field, safety is built into everything we do, from driving the site roads to shipping hazardous materials. As site EHS manager, you are responsible for all aspects of safety on site, such as how and where to store grease and oils and proper disposal of hazardous materials, to name a few. Overseeing that tools are calibrated and PPE is inspected and in the books is another small part of the job.

Safe working environment

The most important part of the job is making sure everyone has a safe working environment. This involves making sure all technicians have their training up to date and scheduling those in need of additional or refresher training.

Every technician hired undergoes a minimum of two to three weeks of training prior to climbing a tower; this includes basic LOTO and first aid, along with climb rescue training. At that point, the technician is set on task with their first crew and assignments. With a lead technician heading the crew, the new technicians are allowed to perform minor functions while shadowed by a seasoned technician. Then, when the technician has been evaluated according to the training, the decision to progress the worker to the next level of training is evaluated and/or scheduled.

Additional training is ongoing, approximately two times a year with most wind-farm owners and operators. This would consist of refresher first aid and LOTO advancements, as well as platform-specific training. Advancing technicians learn special rescue techniques that include rescuing personnel from beneath a gearbox or an unconscious victim in the blade. At EcoTech, we try to focus on the early stages of rescue, the self-rescue, two-man pick, and over the side.

Without proper schooling and training, this would be the technician’s first time working on a ladder. Here we get to work with the students to refine the skills that will get them ahead in the industry. We try to condition them to keep a cool head under pressure and follow the steps they’ve learned in class and climbing lab. Having the climbing tower and platform make it easier for the student to observe each other’s techniques. We also use video like the pros to point out what went right as well as what could have been done better.

New challenges

Safety in the wind industry is always expanding, and with turbines reaching unheard of heights, what new challenges lay ahead for the industry? Offshore is quickly becoming popular in the U.S., and this is new ground in the sense of safety training. We currently have an industry shortage of technicians to work onshore; how do we retrain them to fill the new need for offshore technicians?

Those who are in the industry are working with one another to set the safety guideline for what’s to come. Until then, we will continue to train our technicians to focus on best safety practices including know-how and when to use safety devices and what situation calls for what measures. Our students learn to follow directions and to never skip a process. That one missed step could end up your last without proper training. Most of the fatalities in the wind industry are by undertrained subcontractors; subcontractors who are unfamiliar with wind-safety guidelines are usually the subject of unfortunate events.

The key is to properly train your employees for any possible emergency scenario, so if the need arises, they know what to do in that situation. As an instructor, we have a duty to protect our students and to make sure they can identify and isolate power in the systems.

This is where LOTO is introduced and the numerous devices for our protection. The how and when to use certain devices add to the skillset ingrained into the future technicians. We focus on giving the student the edge in the job market and add valuable skill they retain for a lifetime.

Face it, at the end of the day we all want to go home to our loved ones in one piece. If we can teach safety the right way and early enough, everyone gets to go home at the end of the night. Safety is more than a word; it’s a culture and lifestyle worth living.