Proper wind-turbine inspection can mean the difference between a fully functioning asset producing power at optimum efficiency and that asset shutting down completely.

To that end, inspection is crucial, but it’s often not treated that way.

CICNDT has worked to make inspection an affordable part of a wind farm’s toolbox for 10 years, although the company’s founder has been doing NDT for almost 30 years.

“We work with our customers at different levels to bring a capable inspection solution,” said Jeremy Heinks, founder and president of CICNDT. “We try and keep it a little bit on the more affordable side because, unfortunately, NDT or any quality-related process is usually the first to go when there are cuts. We want to make sure that doesn’t happen.”

CICNDT offers inspection services which includes Ultrasonic (PAUT/Array/Laser), Thermography, Laser Shearography, Bond Testing, Eddy Current, along with Robotic CT — in addition to equipment sales and application support, according to Heinks.

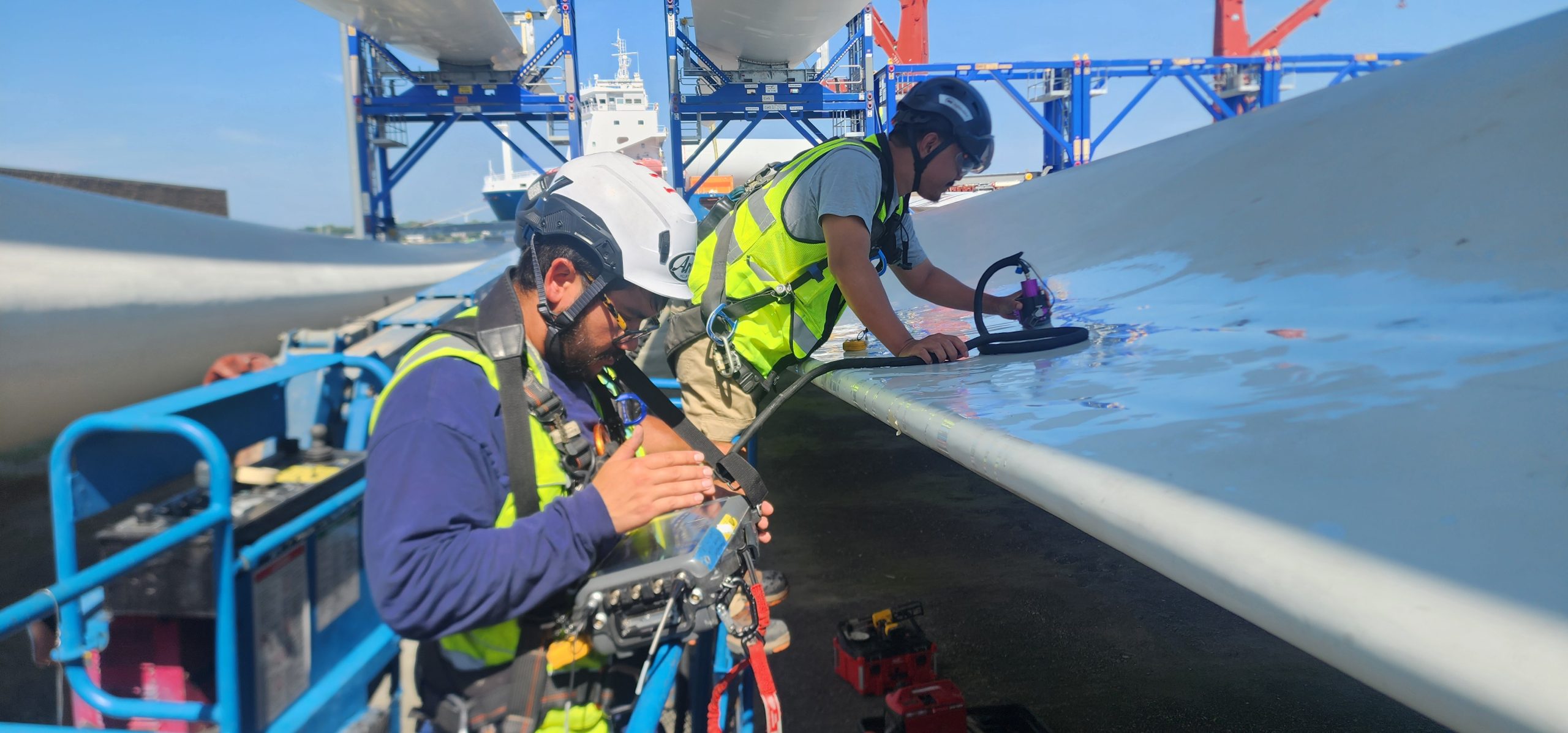

“We’re global; we bounce around all over the place,” he said. “Wherever the work’s at, wherever the problems exist, we are able to get to them. We do up-turbine inspections, and we do rope inspections. We do a lot of engineering type tasks where we work with blade engineers to figure out what we need, whether we need inspection or monitoring or if the turbine should be shut down for safety.”

Heinks said CICNDT is also working on robotic systems that will be ideally suited for offshore wind.

“We’ve got a partnership with Sandia National Laboratory for a robotic crawler, so we can bring that out,” he said. “That’s going to do really well in offshore where accessibility is a big issue or with these large blades that are 100-plus meters.”

Network of engineers

CICNDT’s approach to inspection challenges is to have a valuable network of available engineers who can get to work immediately on a client’s needs, according to Heinks.

“We’re starting to get more internal capabilities on the engineering side, but, I’ve got a network of really knowledgeable blade engineers, and I reach out to them and work with them,” he said. “I am of the belief that there’s enough work for everybody. There’s a ton of work out there when it comes to wind, and we’ve got to keep these different groups fed and alive to be able to do this stuff, and it’s good practice to spread the love, spread the wealth.” Working with third-party companies has only served to enhance CICNDT’s expertise and efficiency, according to Heinks.

“As a manager of NDT groups, I have always worked with third parties because, a lot of times, as a manager from a company, you didn’t have the bandwidth or you didn’t have the right training or expertise, so you’re always looking to bring that on if you don’t have it inside the company itself,” he said.

Equipment sales

As far as equipment sales goes, Heinks said it includes “a little bit of everything.”

“Let’s say we have a customer come to us, and they really want to internalize an inspection,” he said. “They might have the staff, or we might have to train their staff, but the larger groups will want to make this their own. We’ll build a system — whether it’s ultrasonic or infrared or laser — with a bunch of different methods we use, and we’ll sell that to them. We’ve got good relationships with a lot of suppliers, so we’re pretty flexible when it comes to method cost-effectiveness. A lot goes into making those decisions. It’s not just a, ‘Hey, this is the best thing ever.’ Because, if it’s the best thing ever, and your company can’t afford it, then it’s not the best thing for you. We try and focus on what’s affordable and what’s actually practical.”

That often boils down to offering customers the most practical solution, according to Heinks.

“We want a robust solution, and we want an effective solution,” he said. “It goes back to: You can have the greatest thing ever, but if nobody in your company can use it because it’s too complicated or it’s too fragile for the field, then it’s going to sit on a shelf. You look at the big guys in the industry. They’ve bought million-dollar machines that are sitting on a shelf because they just don’t know how to use them anymore, or it might’ve looked good in a lab, but once it got in the field, it just wasn’t something that anybody could use. It wasn’t practical. Our focus when it comes to anything is to make sure that, whatever we bring, it’s going to be actually used and survive the environment it’s put in because, up-tower in those conditions, it’s some of the roughest conditions you can get into with this type of equipment.”

Servicing the end user

This philosophy has served CICNDT well over the years, according to Heinks, in that developing inspection solutions for end users and insurance companies has become an appreciated part of CICNDT’s work.

“With an end user or insurance company, we’re out there, and we’re trying to save a turbine or sometimes a whole farm depending on how widespread the defects are in the blade types,” he said. “We’ve evolved to transfer over to supporting the end users more. The other thing is, early on, you try to push faster, fancier high speed inspection options, but a lot of times it’s just going back to the basics and sticking with what works. That’s what we lead with now. Those are pretty manual inspections, but they’re more cost-effective.”

Part of that cost effectiveness is making sure the right questions are asked before a job begins, according to Heinks.

“First off, we try and get as much information from the customer as possible about the material, the blade type, what they’re seeing, and their expectations,” he said. “A lot of times it’s like calling the fire department or 911: They want the solution now. And, more often than not, we can show up fairly quickly, but when we get there and we don’t have any information, we’re going to waste a lot of time trying to figure out what we’re actually looking at. We’ve progressed at trying to ask the right questions. We put together a questionnaire, and we get that out right away to the customer, and that forces them to think about their problem a little bit more. This gets everybody on the same page as far as expectations go and what can actually be done about the issue.”

Connecting to others in the sector

Heinks is quite proud of how his company has been able to connect with and work with groups that CICNDT has trained and brought into the inspection side of the industry.

“We have a facility in Ogden, Utah, and we’re going to be putting together a training group out of there in the near future and, hopefully, partner with Sandia on that as well,” he said. “I’m most proud of the partnerships and the people we’ve been able to work with. When I was the NDT manager for LM Windpower for four years, by the time I left, I had 200 inspectors in eight countries. And in a lot of those countries, when you get into the NDT field, you’re basically at an engineer level at that point, and that pay differential between general worker bee and engineer in places like India and China is massive. That’s changing your whole family. We’ve done similar things. I’ve done a lot of training like that with some of the other OEMs. That’s probably one of the proudest things CICNDT has done is being able to spread that knowledge and skillset.”

Aerospace

CICNDT’s inspection services are not limited to only wind, but to the aerospace sector as well, according to Heinks.

“There’s a flow of technology between space and aerospace and wind, but we do about 50/50,” he said. “Half of our business is wind service. The other half is space and aerospace. The cool thing about that is, right now, we’re working on a lot of really advanced stuff that eventually we’ll be able to trickle into wind. That’s a big focus, especially with our new AIMM Center of Excellence in Ogden. We’re going to try and bring those technologies that we have in-house and see what they can do for wind blade parts, materials, and robotic CT.”

Ultimately, being able to use methods developed for aerospace and adapt them for wind will make inspection even more efficient, according to Heinks.

“That’s something we’re trying to add to the industry because, up until now, you’d get a defect, and in order to do testing on it, you’d dissect it,” he said. “And, typically, when you dissect wind blade parts, you use a giant gas-powered saw, and that’ll destroy the sample as much as it gets to where you need to go.

But, with robotic CT, we can do much larger parts, and we can see everything going on without taking it apart. Hopefully, things like that will help us understand defects better in the future.”

More info www.cicndt.com