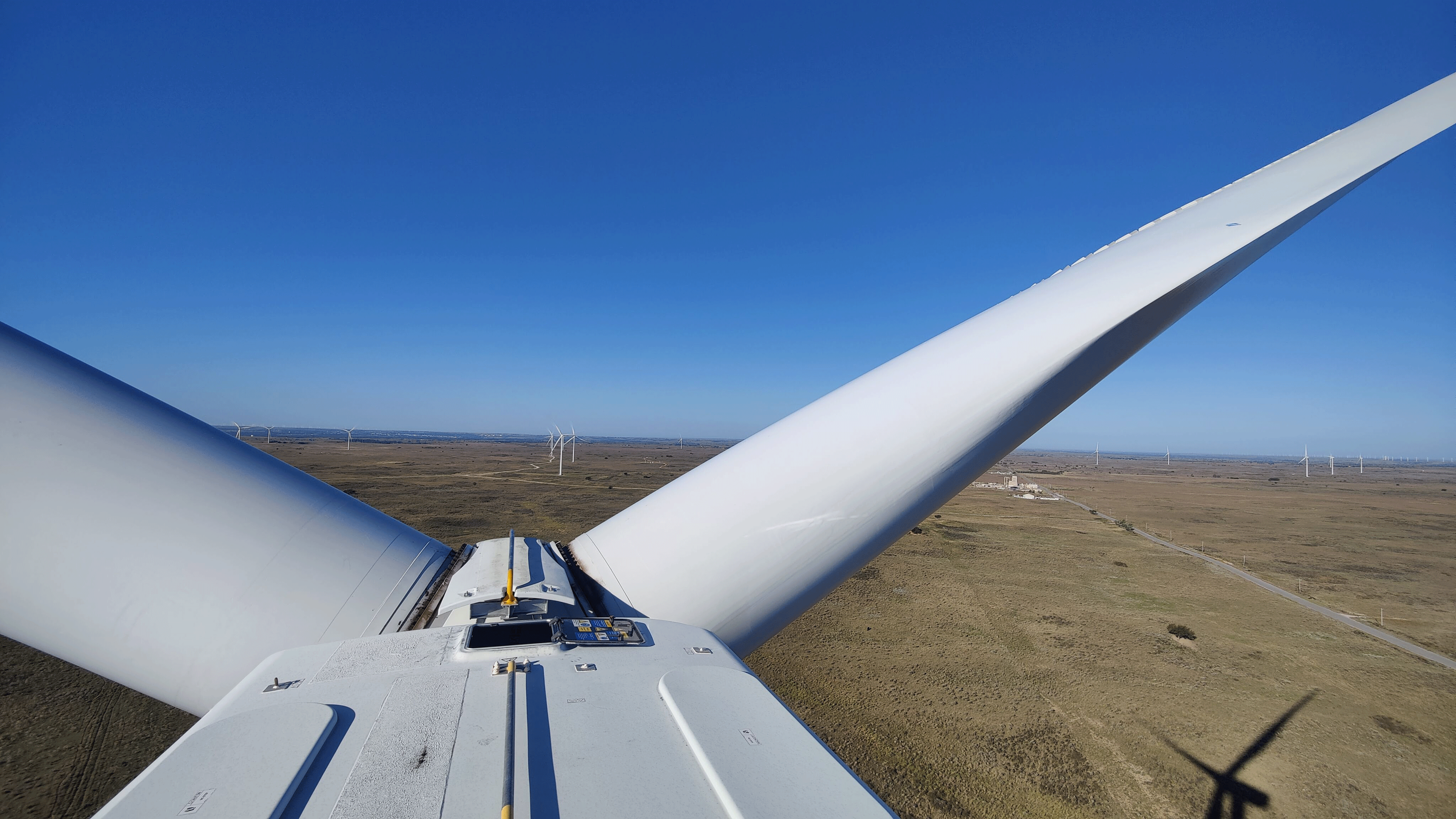

Predictive maintenance for wind turbines has become a cornerstone of what keeps those massive assets spinning efficiently and safely. A big part of the predictive maintenance toolbox is the condition monitoring system; however, until recently, there hasn’t been a reliable condition monitoring system that could keep an eye on a turbine’s blades and provide early detection of any potential threats.

Predictive maintenance specialist ONYX Insight recently acquired ELEVEN-I to help solve this industry challenge.

“ONYX focuses on providing holistic solutions to our customers, primarily owner-operators and OEMs, to equipment with the right hardware and software and analytics to reduce the downtime and reduce their OpEx throughout the lifecycle of their wind projects,” said Dr. Zhiwei Zhang, Chief Commercial Officer at ONYX Insight.

Monitoring the blades

ONYX’s acquisition of ELEVEN-I means the company can more closely and accurately monitor the health of the wind blades, arguably one of the most important components of a turbine, according to Zhang.

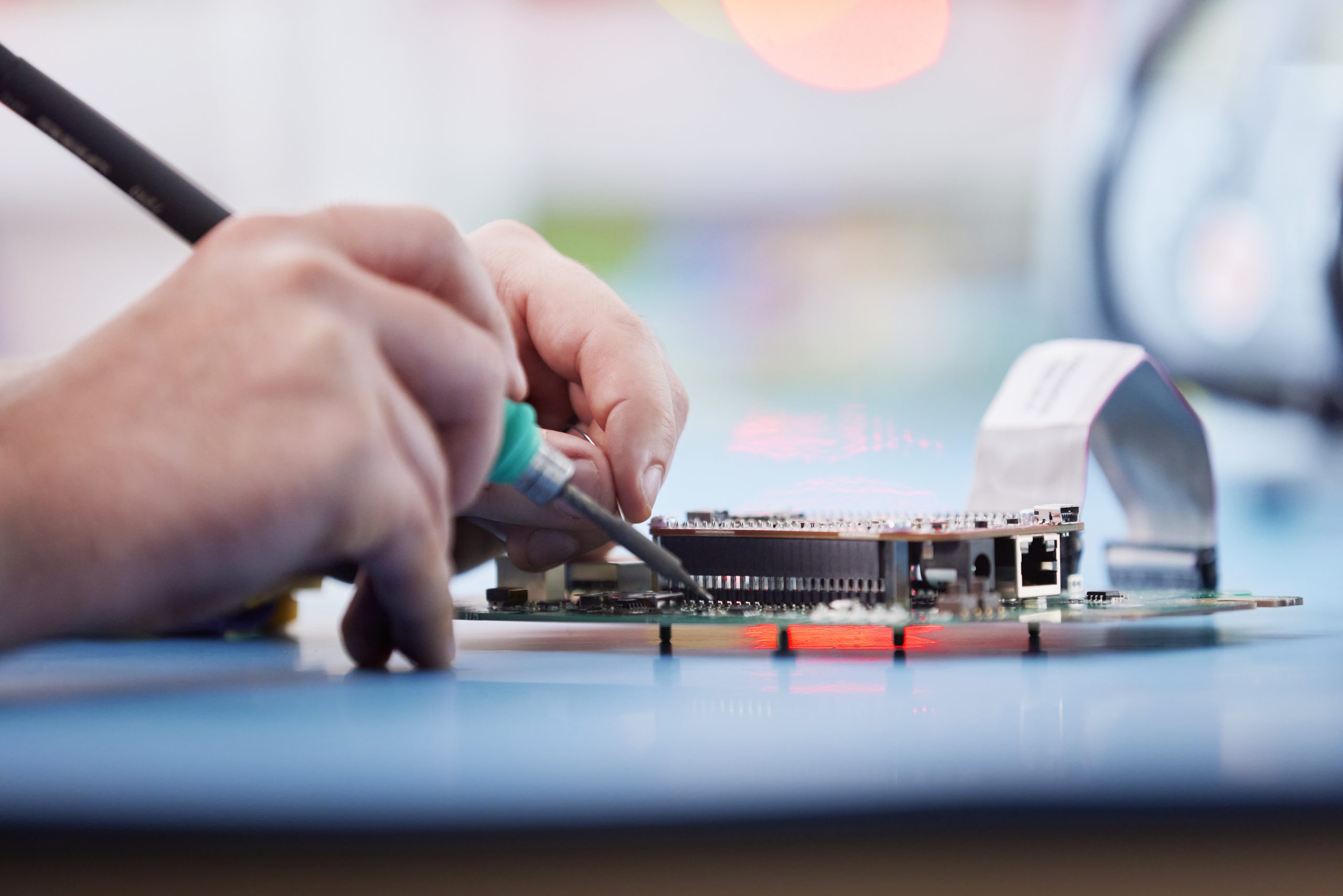

“Over the years, ELEVEN-I has developed a technology that has its own sensor, hardware, and analytics to monitor the blade health and blade dynamic behavior in the field and compare it with the design and the intention,” he said. “They use a mixture of physical-based models and advanced analytics based on field data, and they provide insight to the blade structural changes, damage accumulation, and any abnormal behavior from the field, helping the owner-operators to detect blade issues earlier and make better informed decisions during their maintenance.”

Zhang emphasized that ELEVEN-I’s mission meshed very well with ONYX’s, which focuses on providing a whole holistic solution for the entire turbine for owner-operators.

“It has always been our vision to cover all turbine systems to provide predictive maintenance to our customers where needed,” he said.

“We focused on drivetrains to start with about 15 years ago, and then on gearboxes and generators. Lately, we have been able to expand to other components of the wind-turbine systems like towers and foundations and the pitch bearing systems, the blade root interface.”

Adding to its portfolio

But with blade failure issues being a huge challenge in the industry today, ONYX was researching ways to add that crucial component to its portfolio, according to Zhang.

“They’re costing our customers a lot of money, and blade CMS — the blade condition monitoring system — is a relatively new emerging technology that is only starting to gain traction in the industry,” he said. “The timing was just perfect for ONYX to expand into blade monitoring. With the ELEVEN-I acquisition, we will be able to accelerate into this new area more quickly and capitalize on this once-in-a-lifetime opportunity.”

ELEVEN-I’s blade CMS system has had a proven track record after six-plus years of development and with research projects with major OEMs, according to Zhang, as well as acquiring an offshore research grant in the U.K. and elsewhere.

“We have seen some pretty convincing and successful field data from their installed base,” he said. “In the meantime, we have actually collaborated with ELEVEN-I in the past year or so on multiple customer projects, using them as a subcontractor. Our due diligence included ONYX-led installation with their systems for our customers and back-to-back blind tests of their analytics on a damaged blade in the U.K. And we had the opportunity in the past few months to demonstrate the system’s effectiveness in the field, and we’re convinced that this is a great fit to our product portfolio.”

Affecting the bottom line

Being able to monitor blades effectively can solve a lot of challenges for owner-operators that, until now, could severely affect a company’s bottom line.

As turbines grow in size and complexity, blades face higher loads and increasing challenges in manufacturing and transportation.

Early detection could convert blade replacements to blade repairs — a far less costly option. It would also supplement the need to rely on annual drone inspections.

Blade issues can escalate into catastrophic events, which could be anything from blade detachment to full turbine collapse.

Eliminating severe events can help minimize reputational damage and increased scrutiny from safety, insurance, and investment committees.

Those factors are just a few examples of what made ONYX take notice of ELEVEN-I’s growing expertise with blades, according to Zhang.

“We’re able to expand our PDM area from gearbox to drivetrain, and then blade gap, pitch bearing, and tower and foundation system; we’ve done a lot of research work and engineering work that went into the plate structure, which has been supported by some government funds in the past a few years, but it wasn’t going at the speed we wanted or needed it to,” he said.

“With Eleven-I’s specialty and what they have proven they could do in the blade health monitoring area, it just matches with what we do today really well.

It’s accelerated what we want to do on the blade health monitoring area perfectly.”

Making sense

And with a large portion of the O&M’s budget earmarked for blade and other major components of the turbine, being able to develop and offer early detection systems of potential threats made sense, according to Zhang.

“With ELEVEN-I’s condition monitoring system on the blade operators, customers will be able to get early detections on those issues, especially for those issues that happen in between the drone inspections that customers are probably doing, sometimes annually, and sometimes more often than that,” he said. “Basically, there’s a gap of visibility for our customers in between those inspections. With ELEVEN-I’s system, they will be able to get much better visibility and be better informed of any issues happening and make their plans either to do a one-off inspection with drones or to prepare for repair or replacement, to catch the issues earlier and plan more proactively.”

One-stop shop

Also, by adding blade condition monitoring systems to its arsenal, ONYX can even better be a one-stop shop for its customers, according to Zhang.

“In the whole turbine, there are a lot of subsystems, and not all of them need monitoring,” he said. “But, from all these years working in the wind industry and what we have learned from our customers is there are only some critical major components that need monitoring — for example, the drivetrain, the blades, and a few others. When the customer needs monitoring on all these major critical components, our understanding is the customer won’t want a few siloed condition monitoring systems that they need to keep adding — let’s add another CMS for the tower, let’s add another CMS for drivetrain, and then the blades.”

The more systems a company has to incorporate, the higher the cost, as well as the added complexity of learning multiple systems, according to Zhang.

“Our understanding is the customer would want one consolidated system that covers all the components that need monitoring, and then they can have a centralized dashboard and centralized database as well to keep learning from all these issues and repairs from their system and, later on, build a central repository of all this health data and issues from their major components,” he said. “That’s our vision.”

Expanding more quickly

ONYX has been doing research and trials on blade condition monitoring over the years with some of its customers, but by bringing ELEVEN-I under the ONYX predictive maintenance umbrella, it has allowed the company to broaden its expertise much more quickly, according to Zhang.

“With the ELEVEN-I acquisition, they have brought in a more mature and technical ready product to us, and we’ll be able to open this market segment more quickly, meaning that we’ll be able to resolve some of the problems for our customers more rapidly,” he said. “For example, I have got requests from customers to monitor certain blade platforms from certain turbine technologies, and they have known blade issues they want to monitor in addition to the joint inspection they’re already doing. With this acquisition, we will be able to provide a solution to market much more quickly than before.”

As the industry challenges grow, Zhang is confident that blade CMS is a significant step for ONYX to expand. “We have been a drivetrain expert for a long time, and we have our drivetrain monitoring solution that’s been established in the market from aftermarket, from owner-operators to OEMs, in the past 15 years or so,” he said. “For blades, this acquisition will be marked as a breakthrough for us in this area.”

And Zhang sees a natural evolution for blade CMS as well, where it becomes part of the initial blade construction process.

“I hope this marks a new phase for ONYX to enter not only blade CMS for aftermarket for retrofitting in the field, but also gets us into a factory-fitted solution for OEMs,” he said. “That means that this product can become so scalable, that not only wind farms will retrofit a post-warranty, but the OEMs will consider fitting this blade CMS solution into their factories and into their assembly lines, so that, eventually, every blade, every turbine, will come with a blade CMS in the future.”

More info onyxinsight.com