A team led by Professor Johann Kollegger at the Institute of Structural Engineering at Technische Universität (TU) Wien has developed a new tower construction method wherein double-wall elements are joined together on the ground to form large double-walled concrete rings. These rings are then lifted up with a crane, stacked one on top of the other, and filled with concrete. This technique results in a construction method for wind turbine towers that is faster and less expensive than traditional methods.

“In wind turbine construction, large precast concrete parts are usually delivered to the construction site,” Kollegger said. “These are then assembled into a tower and then fixed to one another. This method is fast, but the costs associated with the special transportation of large precast parts can often be very high.”

In addition, the tower construction method developed by TU Wien also features thinner walls and less reinforcing steel, which means that significantly fewer resources are being used compared to the familiar precast construction methods.

In addition, the tower construction method developed by TU Wien also features thinner walls and less reinforcing steel, which means that significantly fewer resources are being used compared to the familiar precast construction methods.

A double-walled structure filled with concrete

In recent years, Kollegger’s team has repeatedly created a stir with their new and creative concrete construction solutions, for instance, with a folding bridge or even a concrete dome, which can be formed by inflating an air cushion beneath the concrete. And now a new concrete tower construction method has been developed and successfully tested.

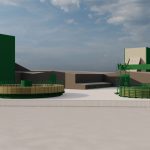

Instead of heavy, solid concrete rings, hollow, rectangular double-walled elements are transported to the construction site. These double-walled elements are erected and joined together in a circle, so that they form a polygonal segment with an outer and inner wall.

“The segments are then stacked on top of one another, retaining the hollow space between the two walls,” Kollegger said. “Only then is the inner space filled with concrete — one segment at a time. A monolithic concrete block is created, whereby the segments are joined together in an extremely stable way.”

The design of the double-walled segments is flexible

“The individual elements are joined together to form a regular nonagon,” said Ilja Fischer at TU Wien. “It is crucial to plan the segments in such a way that they remain stable throughout construction. Then, once they have been filled with concrete, stability is no longer a problem.”

“The individual elements are joined together to form a regular nonagon,” said Ilja Fischer at TU Wien. “It is crucial to plan the segments in such a way that they remain stable throughout construction. Then, once they have been filled with concrete, stability is no longer a problem.”

It is also important that the segments are packed closely together when the concrete is being poured in. Once they have been placed on top of one another using a crane and precisely aligned, the joints are sealed so that the concrete cannot flow out.

Presentation at the Hannover Messe Trade Fair

TU Wien’s tower construction method has already been successfully tested on a test site in Lower Austria.

“The new construction method is simple and fast,” Kollegger said. “The double-walled elements can be transported without any issues. Taking into account all of our experience to date, our new method is expected to be economical and capable of establishing itself compared with the previous construction methods. We believe that our patented process offers benefits for very high wind power stations in particular.”

Source: TU Wien

For more information, go to www.tuwien.ac.at.