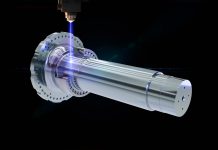

Installing and maintaining offshore wind farms when faced with intertidal areas or shallow water can provide an interesting challenge. However, there could be an answer using an air cushion solution. The heavy-lift Hoverbarge, which Hovertrans engineers have been manufacturing for over 30 years, is an amphibious marine barge capable of transporting a payload of hundreds of tons on a cushion of air.

The Hoverbarge system can be utilized to transport heavy equipment over shallow waters, mud flats, and sandbars unaffected by tidal ranges. The Hoverbarge could also eliminate the need for offshore jointing, transporting cable from the shore to deep water. The capability to move heavy equipment efficiently over such areas could reduce costs significantly because there is no need for dredging, constructing, or using quayside infrastructures. Hovertrans has seen an increase over the past month of interest from power and engineering companies looking to use the Hoverbarge system, potentially alongside traditional hovercraft for crew transfer.

The Hoverbarge has proven to minimize environmental impact. Dan Turner, managing and technical director of Hovertrans, says that “The Hoverbarge only exerts 1psi ground pressure compared to a human footprint of 8psi and can avoid the need for dredging. There appears to be great benefits from using a system that minimizes environmental impact when constructing wind farms.”

For more information call + 44 23 8030 2035, send e-mail to Stuart Turner, general manager, at stu@hovertrans.com, or go online to www.hovertrans.com

.