As the telecommunication industry matures, many existing towers are being structurally optimized to improve their load carrying potential for additional antennas. Public opposition and zoning restrictions have limited the number of towers that can be built, forcing tower owners and carriers to collocate new antennas on existing structures. Towers that were originally designed for one set of antennas are frequently being structurally upgraded to handle additional microwave dishes, radios, and other equipment to increase coverage to the growing population that uses cellular technology. Collocating this equipment significantly improves the revenue potential for the tower owner, providing further incentive to structurally modify a tower to handle new loadings. In certain environments towers are also susceptible to corrosion fatigue, which lowers the structural capacity and oftentimes creates safety concerns. Tower reinforcing options also exist to remedy corrosion and reinstate the structural integrity of the tower. To further optimize the towers’ value, owners also have the option of extending the tower height to improve cell coverage and increase the vertical real estate available for lease. This approach is very attractive to tower owners as an alternative to building a new site.

Just as the telecommunication industry has adopted these optimization practices, the wind tower industry is also facing similar challenges as the need to place larger turbines on existing structures surfaces and the towers degrade.

Structural Modifications

To modify a structure to carry additional loading or remedy a corrosion issue, many owners are reinforcing their towers with bolt-on structural steel members, welded reinforcements, clamp-on sleeves, or carbon fiber reinforcing. The added strength provided by the reinforcing enables the tower to support heavier loading or offset material losses from corrosion. Strengthening a structure can be challenging from design, fabrication, and installation standpoints:

• Design—Reinforcing challenges include accounting for correct tensile and buckling capacities in the proposed members, developing the loads in the end connections, and utilizing connections that can adequately transfer loads between the reinforcing elements and tower. Selection of proper reinforcing elements to expedite the installation and decrease equipment downtime is critical.

• Fabrication—Strict QA/QC procedures must be in place with the fabricator to ensure all products are fabricated to the correct design requirements. Galvanizing or other surface protection must be used to prevent long-term corrosion in the upgrade components.

• Field Constructability—Installing reinforcing elements in the field requires a competent climbing crew and strict attention to safety and quality. The reinforcing design and connection details contribute to the constructability, with bolted and adhered solutions preferred over welding to eliminate onsite fire hazards and quality control concerns. Welding may also damage galvanizing on interior pole surfaces in a way that is challenging to access and repair, accelerating future corrosion.

Reinforcing Types

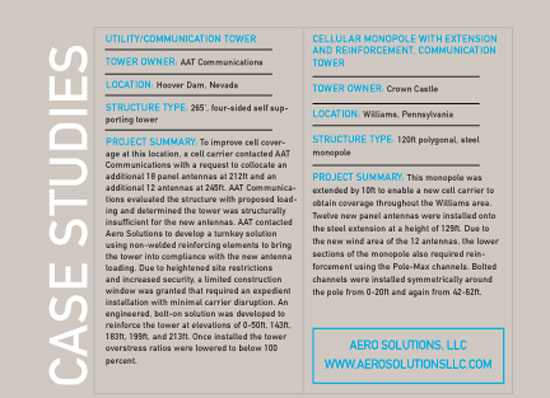

Towers can be classified into three different categories: monopoles, self-supporting towers, and guyed towers. Monopoles are generally used for cell sites located in urban areas and large wind turbines. The steel tubular structures are typically fabricated using customized geometry and high strength steel plate not readily available for aftermarket modifications. Common reinforcing systems for monopoles include both bolted and welded structural steel members connected to the exterior of the pole shaft. Flat plate, bent plate, and structural channels are common choices, with structural channel providing the best value due to higher structural efficiency than flat plat. Pole-MaxTM, a monopole reinforcing product line manufactured by Aero Solutions, is a high strength channel widely used in the telecom market for this purpose. The high strength, galvanized steel channels are bolted to the monopole shaft wall with shear transferring blind bolts. The high capacity blind bolts transfer shear from the reinforcing plates into the pole wall and develop the full load carrying capacity of the upgrade in the end connections. The blind bolts are installed from the outside of the structure and do not require access to the inside to facilitate installation. The bolted connections are recommended to minimize damage to the pole and reduce the risk of fire. Once installed the steel channels can provide a significant improvement in pole capacity, enabling the tower owner to install additional loading or compensate for wall loss as a result of corrosion.

Fig. 2

Self-supporting and guyed towers are lattice structures typically fabricated of solid round, tubular, or angular steel members. Self-supporting and guyed structures are more commonly used for small to medium wind applications, while it is uncommon to find these structures used in large wind applications. The towers have far more structural components than a monopole and require a different approach for reinforcing. Depending on the geometry of the tower, a bolted steel solution can be used to reinforce overstressed members, or carbon fiber composites to provide additional strength. Both solutions provide a safe alternative to welding.

Tower Extensions

Extensions enable owners to increase the revenue potential of their site while also preventing carriers from building a new tower. Extensions have become very popular in the telecom industry, specifically in densely populated areas where land is limited and permitting and zoning requirements are strict. To extend a tower the owner will be required to determine whether or not the structural capacity will allow for the new loading without requiring an upgrade. In some cases the addition of an extension will overstress the tower, requiring the owner to not only install the extension but also install a tower modification.

Extension designs exist for all three types of structures and can be developed to limit the equipment downtime and minimize the resultant loading on the existing structure. Extensions for guyed and self-supporting towers generally require a new tower section to be fabricated with a face width matching the existing tower. Common designs for monopoles extensions include the following:

• Flange to Flange Connection—A design typically requiring a new top flange to be installed on the existing structure to accept the proposed extension. The tower flange can be welded to the structure or connected with bolted brackets.

• Stilted Adapter—A design using bolted, high strength channels to extend the height of the structure.

• Mouse Hole Adapter—A variation of the flanged connection, using “mouse holes” in the new extension to bridge over existing equipment.

Relevance to Wind

As owners in the telecom industry continue to optimize their tower infrastructure, a need is evolving in the wind industry to maximize the revenue potential of existing wind turbines and ensure the continued operation of structures located in corrosive environments. The issues and opportunities faced by the cell industry over the past decade will likely be shared by the wind industry as the quantity of turbines continues to grow throughout the U.S. Steel corrosion, weld fatigue, and other long-term structural degradation will require owners to continually inspect their towers and be prepared for potential modifications.

Extending existing wind towers will enable owners to place larger, more-efficient turbines on preexisting structures. As wind turbine technology evolves, wind turbine owners can allow their tower portfolios to evolve in tandem by extending the structures when needed to allow for larger turbine loading and blade spans.

Note: The author is a member of the U.S. Wind Energy Structures Group, which is a recently formed consortium of the ASCE Wind Structures Committee, National Renewable Energy Lab, and the American Wind Energy Association (AWEA). Aero Solutions is also represented on the TIA (Telecommunications Industry Association) TR14.7 committee, a group that focuses on standards for telecommunication towers.