While the demand for cleaner energy and falling prices has increased the supply of wind power, the growth rate for new wind capacity is falling short of what’s needed to meet the world’s climate targets. One strategy to help bolster capacity is to enhance the operations of existing wind farms by extending turbine lifespan, enhancing performance, and reducing downtime.

The estimated life expectancy of wind turbines is roughly 20 years. Due to their remote locations and exposure to harsh conditions, wind turbines are often subject to extremely high and varying torque loads that result in fatigue wear on rotating equipment such as gearboxes or bearings. Even though these components are designed to withstand severe environments, as the turbines age, they will experience a sharp increase in operations and maintenance costs and their operational life will likely fall short of 20-years.

Unpredictable, variable conditions such as wind speed, wind direction, temperature, and humidity amplify the stress placed on turbine components, which can introduce premature component wear. If left undetected, misalignment, imbalance, looseness, cracks, or other mechanical wear problems can escalate and eventually cause significant equipment damage, machine failure, or even an unplanned outage.

The National Renewable Energy Laboratory’s (NREL) Gearbox Reliability Database (GRD) shows that 76 percent of wind-turbine gearboxes failed due to bearings, while 17 percent of failures were caused by gears. Additionally, a member of STLE notes bearing failures in wind turbines can be expensive due to lost production and costs associated with component replacement and maintenance.

The total cost of wind-turbine gearbox replacement varies depending on the turbine location, turbine type, gearbox type, etc.; however, gearbox failures on land-based turbines are assumed “to cost about $250,000 to $300,000 per failure event.”

Increase Reliability and Availability

Today, most new wind turbines are equipped with an integrated condition monitoring system, while many older turbines are still operating without a view into the health of the turbine components and related systems.

Implementing a retrofit strategy that includes software and technologies tailored to individual wind turbines, their location, surrounding environment, and how they are operated helps to extend lifespan, increase availability, enhance performance and reduce O&M costs. Including condition monitoring with vibration analysis as a key part of that strategy delivers those results by enabling faster, more informed decisions.

For many operators and owners, it’s difficult to predict upcoming maintenance needs because they lack newer control systems with condition-monitoring capability or their current monitoring system doesn’t use the entire dataset collected from the turbine.

Furthermore, they are operating with “black box” control or software systems that do not provide access to the detailed data needed to customize turbine-specific maintenance plans. Oftentimes, a reliability expert is needed to interpret the limited data that is available and recommend a course of action, which adds cost and prolongs fixing the problem.

State-of-the-art condition monitoring systems that cover all aspects of wind-turbine operations with a focus on vibration analysis can help to quickly pinpoint the root cause of an issue before it escalates. Modern reliability monitoring solutions are designed to simplify operations and maintenance actions by quickly providing recommendations that optimize operating and maintenance choices.

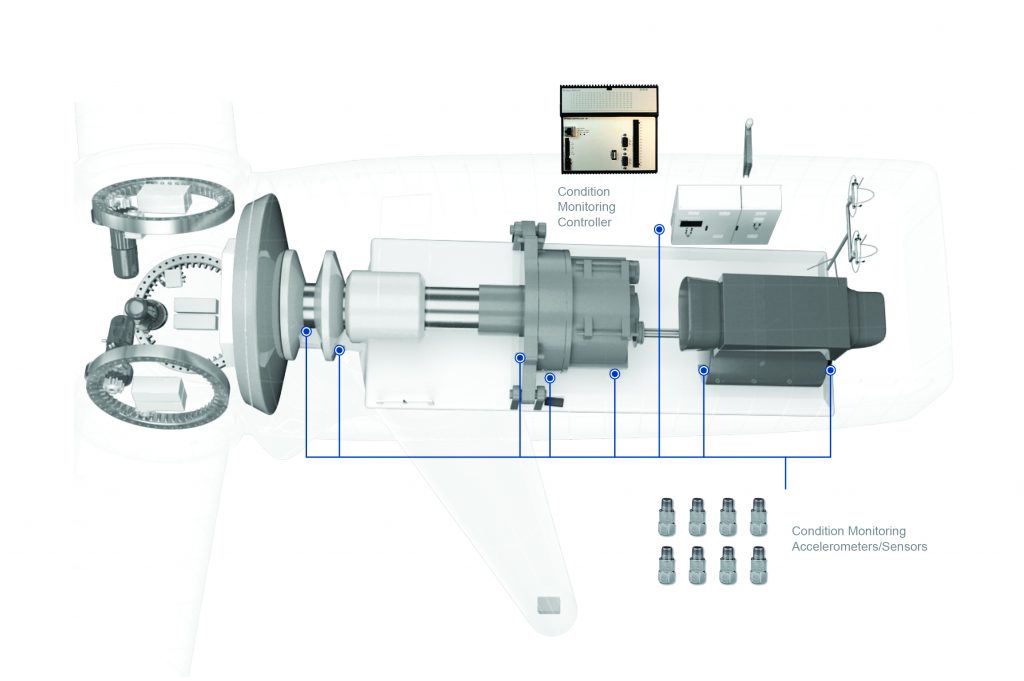

Condition monitoring upgrades should begin with a comprehensive wind-turbine survey to predetermine critical vibration levels and frequency ranges. Proven baseline values from the appropriate International Organization for Standardization (ISO) and The Association of German Engineers (VDI) standards should be used to monitor changes in turbine conditions, comparing key parameters against thresholds. Operational turbine data from the main controller enables accurate analysis of vibrations based on component loads and performance.

A few features and functions to consider when evaluating condition monitoring systems include:

- Strategically placed external sensors that provide accurate monitoring of tower and drivetrain components, including the gearbox, generator, and main bearings.

- Synchronous vibration data sampling for all connected sensors or modules.

- Real-time vibration signal processing based on accelerometer inputs.

- Advanced algorithms for signal processing and data analysis.

- A maintenance-free design without fans and replaceable batteries.

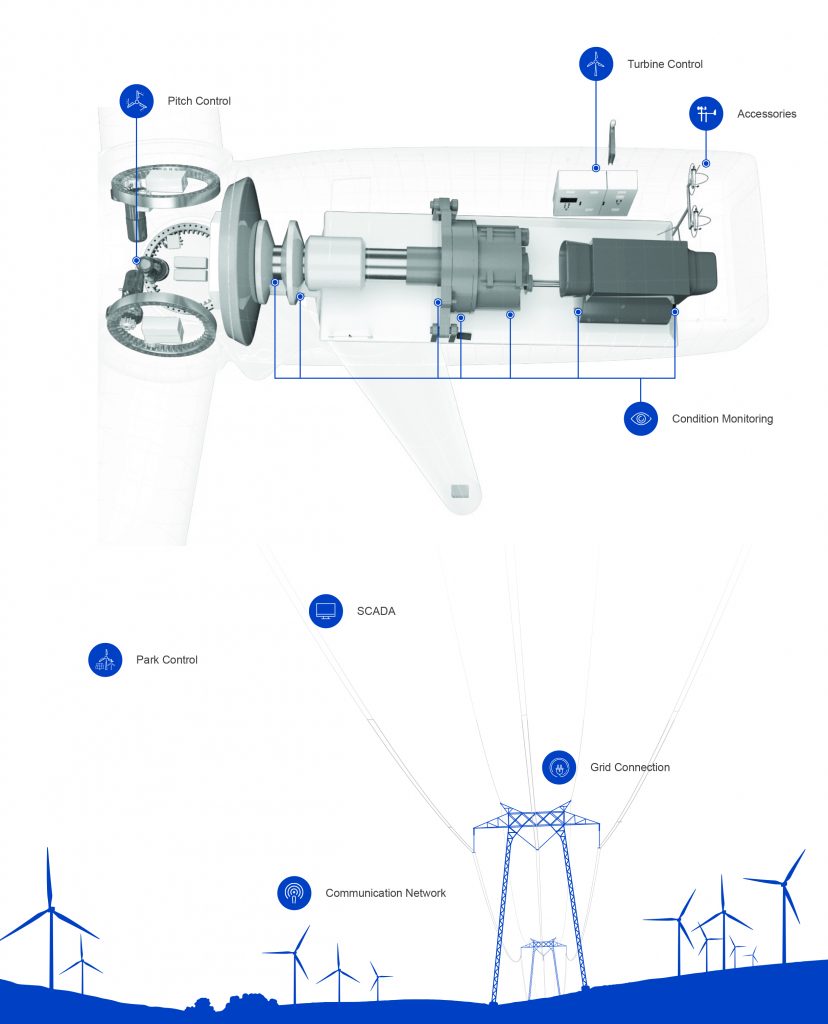

- Easy integration with turbine control and SCADA systems as well as turbine and farm networks.

- Secure data flow, storage, and multi-user access.

- Self-diagnostic capabilities with status indication.

- Scalable software and hardware architecture.

- Flexible configuration and installation options.

- Scheduled or event-based data acquisition.

- Web access to online and offline data.

Not all wind turbines or farms are the same, and no two starting points are exactly alike.

Therefore, the applied condition monitoring system must be adaptable and tailored to meet unique needs with a comprehensive strategy that can be applied to individual turbines or across a fleet of wind assets.

For wind farms comprised of multi-OEM turbines and turbine types, the use of high-performance, vendor-independent condition monitoring software that embraces open standards and protocols enables connectivity to a wide range of devices. Implementing a unified solution streamlines operations and reduces costs.

Focus with a Clear View of Operations

When evaluating condition monitoring solutions, it is important to consider flexible implementation options to meet schedule and budget constraints. These include:

- Installing a standalone system.

- Interfacing with existing turbine controls and SCADA systems.

- Including condition monitoring as part of a comprehensive wind turbine retrofit project.

- Tightly integrated condition monitoring and SCADA systems provide owners and operators with accurate, real-time data and actionable insights to help with decision-making.

As a natural extension of condition monitoring, an intuitive and common SCADA system applied across a wide variety of turbine models and control platforms provides a clear visual indication of turbine health. An intuitive dashboard displaying key production, availability, alarm, and weather-condition information enables users to rapidly identify and mitigate emerging issues, reducing run-to-failure incidents and associated unplanned outages.

Supplement Your Team with Expert Support

Installing and operating a modern condition monitoring solution addresses many wind-turbine health issues. But in today’s fast-moving, resource-constrained environment, owners and operators may not have the bandwidth to carefully monitor the increase in data generated by new software and technology.

Partnering with a trusted adviser who possesses extensive wind industry and certified vibration analysis expertise can supplement an organization’s current workforce, providing 24/7 visibility into the status of turbine operations. Implementing a thorough program of surveillance, alarm management, and diagnostic reporting services ensures optimal turbine drive train performance and operational longevity. Adding reliability consulting services to a condition monitoring or retrofit program can create a complete, proactive asset management strategy to reduce the frequency, duration, and impact of planned and unplanned events.

See, Save, and Produce More

Operating wind turbines with a condition monitoring solution equipped with the latest technologies and software enables non-visible existing and emerging faults to be identified earlier in the failure curve. Instead of reacting to the consequences of an accelerating issue, wind-farm owners and operators can proactively apply predictive maintenance strategies to extend the lifespan of their turbines.

Applying flexible deployment options, such as centralized remote operation center systems and cloud-based or mobile applications, provides the right information to the right person at the right time, regardless of location. Using real-time condition data from wind-turbine equipment, impending issues are recognized, diagnosed, and resolved more efficiently.

Automated, continuous extensive monitoring of rotating components reduces unplanned service, risk, and costs while increasing turbine availability and performance.

Investing in a wind-retrofit program with a holistic approach provides wind owners and operators with full visibility into their data and a vivid view of wind-turbine operations, regardless of OEM or equipment type. Adding modern condition monitoring solutions that provide greater insight into equipment health is a practical and cost-efficient way to anticipate maintenance needs before they become more costly, produce more renewable low-cost wind energy, and take an important step toward a more sustainable world.