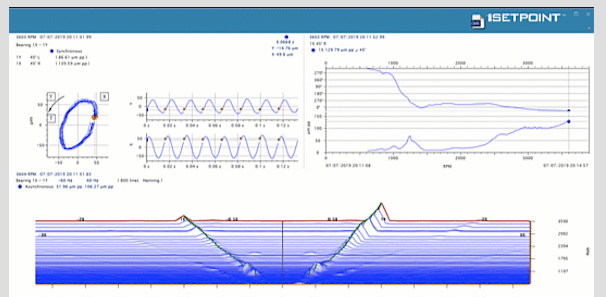

Brüel & Kjær Vibro (B&K Vibro), an independent supplier of condition-monitoring solutions for rotating machinery, has delivered a range of product enhancements for its VCM-3/Setpoint offerings to deliver a single, integrated Setpoint condition monitoring system (CMS) solution.

VCM-3 data can be integrated with VC-8000 data and fed directly into Setpoint CMS to create a plant-wide solution, encompassing machine protection and condition monitoring for both critical and Balance of Plant (BoP) machinery assets.

The new product enhancements will enable B&K Vibro to monitor every kind of asset, from critical (VC-8000) to BoP/auxiliary (VCM-3), integrating with Setpoint CMS and providing an improved diagnostic experience to sites in both hazardous and non-hazardous areas.

“B&K Vibro has listened and responded to our clients’ needs for enhanced functionality and tighter integration across the range of solutions we offer,” said Thomas Carvalho, commercial platform leader, Edge Devices.

“These improvements will provide additional value by allowing a single view of all asset types, delivering faster analysis, and diagnosis of impending issues, which means improved uptime for end users. We now have a complete range of asset monitoring solutions for both critical and auxiliary machinery.”

More info www.bkvibro.com