Wind turbine blade damage is on the rise — and it’s costing the global wind industry more by the minute. Recent failures include a 30-meter blade breaking off in Plymouth, Massachusetts, and a triple failure in Perth, Scotland, where not just one, but all three blades from a turbine detached. Just two brief examples in a catalog of thousands globally.

Recent research found that turbine blade repairs in the United States alone exceeded $1 billion this year. Considering the growing number of wind farms built during the last five to 10 years, plus the cost of blade repairs (approximately $30,000) and blade replacements (circa $500,000), the numbers quickly add up. However, costs — and their underlying causes — extend beyond blade repairs and replacements alone, reflecting a more intricate combination of factors.

As turbines grow, so do risks

The push toward bigger and more powerful machines is piling pressure on manufacturers and supply chains. Over the last few years, the majority of major OEMs have invested heavily in developing scaled-up versions of previous models, with machines exceeding 15 MW already being deployed on some projects.

This is particularly notable among Chinese manufacturers, who have been at the forefront of this push for magnitude. For instance, Guangdong-headquartered Ming Yang installed the largest offshore turbine in the world last year, with 128-meter blades. The company also announced a 50-MW ultra-large floating turbine, setting a new record for single-unit capacity in floating offshore wind.

Generally, the larger the turbine, the more expensive and difficult it is to maintain. Another problem with expedited innovation is that it frequently goes hand-in-hand with quality issues. Research in offshore wind has found that larger turbines — those over 8MW — face substantially higher instances of failure (55 percent) in the first two years of operation compared with those under 8 MW.

Increased pressure on supply chains

A potent combination of macroeconomic, resource, geopolitical, and logistical factors are continuing to put supply chains under immense pressure. When unforeseen circumstances lead to an urgent need for a blade to be swapped out, companies are frequently unable to source replacements fast enough. Those turbines can remain inactive for extended periods, ratcheting up costs and lost revenue for owners and operators.

In addition, the soaring number of blade failures — precipitated by the sector’s expansion, with more than 23,000 turbines installed last year — means trained engineering staff and specific machinery, such as cranes and large-scale transport vehicles, are either stretched or entirely unavailable, adding another layer of expense and headache.

The threat of reputational damage

Although difficult to quantify, and superficially non-financial, the reputational impact following a blade or full turbine failure is no less consequential for wind-project owners and operators. Asset managers know very well that one of the central aspects to a successful wind farm is ensuring the local community feels safe, informed, and respected. Negative media reporting, local community distress, and frayed relationships with local policymakers can be hard for a business to overcome.

Blade failures have encouraged regional authorities to shut down entire sites as a preventative measure while the root cause of the incident is being established and dealt with, and safety inspections are conducted across additional turbines to ensure no further risks of failure.

This was the case at Vineyard Wind in Nantucket in July 2024, when local authorities shut down the multi-billion-dollar project following a blade failure on one of the offshore wind turbines. The incident escalated from a local to a U.S.-wide story as the region’s beaches were closed to swimmers and parts of the turbine started floating ashore. Investigations into the incident and its potential long-term impacts are ongoing, with local communities still expressing anger and apprehension.

Prevention is better than a cure

Blade damage can be unpredictable and highly complex. While a small minority of blade failures might be impossible to prevent, the vast majority can be spotted and dealt with early, and before the problem spirals. The key is having a real-time understanding of a blade’s condition that enables asset managers to catch early-stage issues.

The current, and dominant, practice in the industry is to conduct intermittent (generally annual) drone inspections to check on a blade’s condition. While this approach can be effective at spotting pronounced external issues, it is not adequate on its own. Numerous issues, such as smaller or internal defects, remain undetected and are allowed to worsen, especially given the temporal gap between inspections.

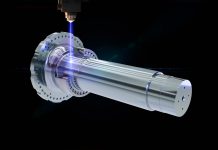

With the proper blade condition monitoring system (CMS) technology, developers are able to identify a significantly higher number of precise blade issues and failure modes at a point where repairs are much more manageable and substantially cheaper.

Thankfully, a growing number of owners and operators are introducing blade CMS into their wind portfolios, enabling them to take a proactive stance on maintenance and performance analysis. Using vibration and displacement technologies provides a granular level of real-time data that allows for an unprecedented degree of practical insight and cost-effective interventions.

As turbines grow bigger and the stakes rise, proactive blade monitoring is no longer optional — it’s essential. Blade damage may be inevitable, but spiraling costs don’t have to be. By leveraging continuous monitoring and actionable insights, the wind industry can turn potential setbacks into opportunities to safeguard assets, communities, and the bottom line, creating a platform for safer, more efficient, and resilient energy generation.