The share of wind energy in the electricity mix is steadily increasing around the globe and is accompanied by a growing need for efficient and high-quality wind turbines with the “Made in Germany” seal. The rotor blades are the centerpiece of a wind turbine, with their production and maintenance subject to rigorous testing procedures. An innovative radar scanner from the Fraunhofer Institute for Applied Solid State Physics IAF can detect defects in the material composition of the wind turbine blades with far greater accuracy and visualized in a cross-sectional view, thereby saving costs in production and operation.

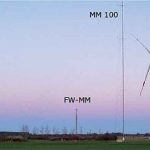

Wind power has become an indispensable part of an environmentally friendly power supply. Approximately 50 GW, equivalent to 12 percent of the total power in Germany, are generated by more than 28,000 wind turbines — with an upward trend. According to the Global Wind Energy Council, the global wind-power capacity will quadruple to 2,110 GW by 2030 — constituting 20 percent of the global electricity supply. Therefore, it is all the more important for this growth market that wind turbines become more efficient, more reliable, and more durable.

According to industry experts, weak points in blade production, for example, could result in unplanned additional operation and maintenance costs amounting to several hundred thousand euros over the entire service life of the turbine. To increase the efficiency and reliability of wind turbines, Fraunhofer IAF has developed a material scanner for checking the quality of rotor blades. Using radar-based technology, defects in the material composition of the wind-turbine blades can be detected in even greater detail.

Identifying Defects

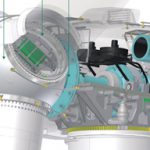

The rotors, which are usually equipped with three blades, are the central component of all wind turbines. They convert wind into rotational energy, and then into electricity. Much like the wings on an aircraft, the blades are subjected to enormous external loads and therefore must be designed to be extremely robust. Modern wind-turbine blades are mainly constructed from glass fiber and carbon fiber reinforced plastics (GFRP/CFRP), so they can elastically absorb the wind energy from strong gusts without breaking. For a single blade, up to 100 sheets of glass fiber webbing are layered on top of each other, shaped and then glued together with epoxy resin. Quality control is essential at this stage in production.

“The difficulty lies in layering the glass fiber sheets flat before they are glued, without creating undulations and folds, and avoiding the formation of lumps of resin or sections of laminate, which don’t set when applying the epoxy,” said Axel Hülsmann, coordinator of the radar project and group manager of sensor systems at the Fraunhofer IAF.

These kinds of defects, as well as delaminations or fractures, can be identified on a large-scale using infrared thermography.

“Our material scanner enables defects to be identified with even greater accuracy, as depth resolution is also possible with radar technology — even in places where ultrasound methods fail,” Hülsmann said.

Cross-Sectional Profiles

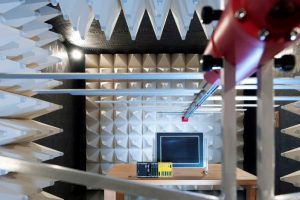

At the core of the material scanner is a high-frequency radar, which operates in the W band between 85 and 100 GHz with only a few watts of transmitting power. Specialized software is then used to process the transmitter and receiver signals and visualize the measurement results.

“This enables us to generate a cross-sectional view of the blade, in which defects can be identified in the millimeter range, and makes our material scanner significantly more accurate than conventional methods,” Hülsmann said.

The radar module is based on indium gallium arsenide semiconductor technology. It is extremely light and compact due to its monolithically integrated construction, in which different components and functions are integrated into a single chip. Measuring 42 mm x 28 mm x 79 mm, it weighs 160 grams. It has a low power consumption of about 5 watts and is fitted with an integrated microcontroller that emits measurement signals via an internet interface.

Future improvements will see the module’s frequency range extended to 260 GHz into the so-called H band.

“This will quadruple the bandwidth of the radar module from 15 GHz to over 60 GHz,” Hülsmann said. “While the resolution of the rotor blade cross-section is already very high, our aim is to improve it even further.”

Lower Maintenance Costs

In addition to its use in the production of rotor blades, in the future, the Fraunhofer IAF material scanner also may find a role in maintenance, where it could be used to classify defects, such as those caused by the impact of birds.

“Currently, the routine testing of rotor blades is mainly performed by hand: An expert knocks on the blade with a hammer and can tell from the tone whether there are any defects in that section,” Hülsmann said. “An automated solution, supplemented by our radar technology, could vastly reduce the downtime of wind turbines and thus save costs.”

This is particularly true for the manual maintenance of offshore wind turbines, which must be reached by boat, sometimes on harsh seas — a time-consuming process.

Alternative testing technologies, such as ultrasound solutions, are extremely difficult to integrate into maintenance procedures.

“Water or gel has to be utilized as a coupling agent, as every air pocket between the sensor and measured part muffles the ultrasound signal to a considerable extent,” Hülsmann said. “While this entails certain side effects, it is nonetheless possible when checking for defects during rotor-blade production. But applying water or gel to wind-turbine blades, which are 100 meters in the air, is extremely complicated. Because it allows for non-contact remote sensing, radar is the optimal solution in this case.”

The radar scanner from Fraunhofer IAF can contribute to the development of innovative material inspections in other industries as well — for example in the aircraft industry. In newer aircraft such as the Boeing 787 Dreamliner or the Airbus A350, the wings in particular are mainly built out of lightweight composite materials.

“In the aircraft industry, as in the plastics industry, an accurate and rapid defect test during both production and maintenance can save costs and prevent damage caused by material fatigue,” Hülsmann said.

Source: Fraunhofer Institute for Applied Solid State Physics

For more information, go to www.iaf.fraunhofer.de