The path that brought Sotek to the wind industry is a bit serendipitous.

The company had been a leader in the manufacturing of precision metal stampings used in large motors and generators for more than 30 years when it was introduced to wind energy about half a decade ago at a trade show.

“A lot of these shows kind of showcase the internal components of motors and generators, and at one of those shows we crossed paths with a company that needed to manufacture wind generators,” said Joe Doino, director of business development with Sotek. “We made the connection there.”

And what Sotek discovered was that the transition to wind ended up being, well, a breeze.

“The reality was, it’s very similar to the large motor and generator components that we were already making,” he said.

About the only step Sotek had to change was modifying the specific generator assembly process in order to accommodate the overall size and putting the large shafts in place, according to Doino.

“The changes we made are not wind related; it’s really just a product specific process,” he said.

Creating stators & rotors

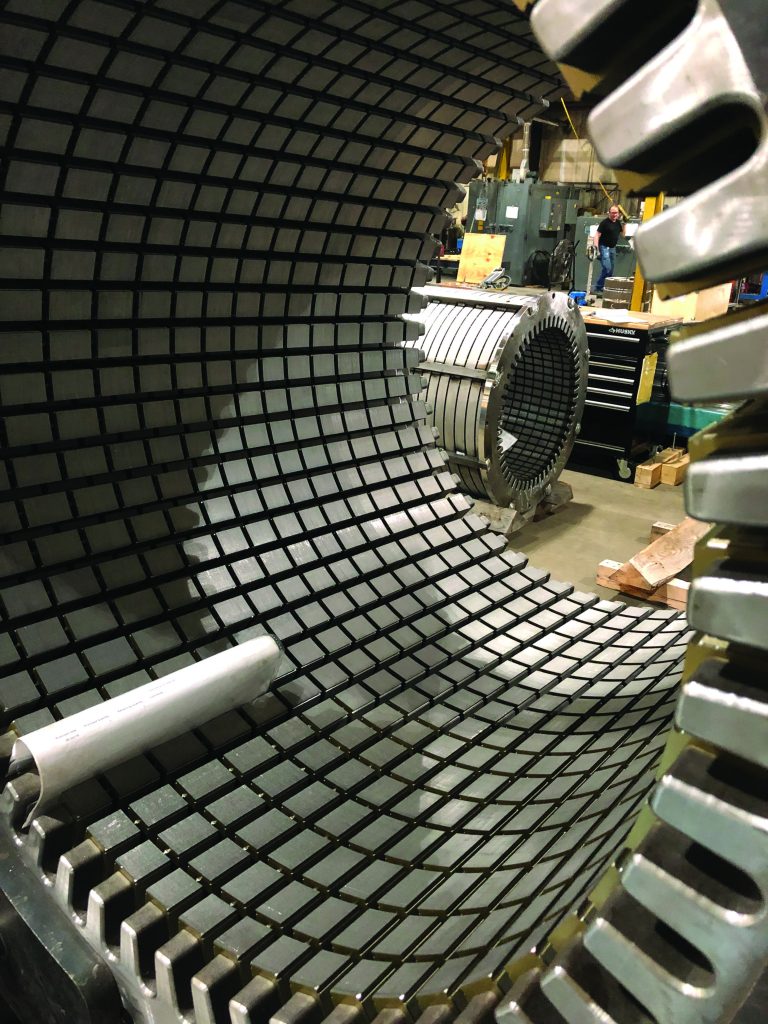

Now, Sotek makes stators and rotors for wind-turbine generators.

“That starts with making the tooling and stamping and the laminations that go into the stators and rotors,” Doino said. “Then we manufacture and purchase a combination of the balance of assembly, the compression and welding here in house to make completed stators and rotors just prior to insertion, whether it’s copper or magnets or whatever the customer’s next step would be, that’s as far as we currently take it for this customer.”

“We provide more or less components and services based on what each customer needs,” he said. “Using both in-house expertise and close industry partnerships to provide the most value for a customer’s project goals, we have space and expect to continue our expansion as our wind business develops, and there are new customer needs to be met. They drive our expansion.”

Specifically, the company can stamp generator laminations or segments of any diameter up to 48 inches wide, handle five-ton rotor or stator assemblies and do machine compression to 200 tons. It also offers an interference fit shaft insertion with a dedicated 16,000 square feet under crane area that includes a manual lathe with a 48-inch cross slide swing. All the steel work is done by Sotek, which it’s been doing for more than five years. Sotek is proud to have generator components on almost 2,000 wind turbines, according to Doino.

Many different markets

In addition to serving the wind market, Sotek also has its hands in other industries, including hydro, rapid transit, electric drives, defense, mining, steel, and oil & gas.

Sotek is able to help customers with new OEM manufacturing, stator and rotor repair, rebuild, end-user, value-added services such as fabrication, assembly, sourcing options, and streamlining production bottlenecks and delivering products whenever or wherever they’re needed, according to Doino. The company boasts an 80,000-square-foot manufacturing and warehouse space that is stocked with more than 3 million pounds of electrical grade steel inventory, allowing Sotek to react quickly for a wide range of applications.

Growing wind market (Growin’ in the wind)

But Doino sees the wind market growing within Sotek’s ranks.

“We’re relatively new to this industry, but we see terrific opportunities,” he said. “There is very strong growth coming, a lot of news; the industry is bustling, and we see it as an increasingly large, key part of our future. It might be a fraction of our current business; our goal is to double or triple where we are now. We’re committed to our value-added strategy and growth in wind power.”

Power generators are considered Sotek’s specialty, according to Doino, and the company is always striving to help its customers find the right solution to whatever challenge they may bring to the table.

“We have people that have been doing this with us for a really long time,” he said. “They are making stampings, laminations, lamination stacks, cores, and these types of assemblies. With the expertise at work in our team, we can guide the customer to something that is easier to manufacture, more cost effective, and takes less time. We consult with them in these ways to improve the overall process because we do have a lot of experienced folks within our company. Some of our experts have been hands on with us from the beginning.”

The start of Sotek

That beginning was 35 years ago.

Sotek opened its doors in 1984 with 13 employees, when the company founder bought tool room assets from Westinghouse Electric Corporation’s motor division. Sotek used the equipment to create specialty tooling and dies.

“When Westinghouse closed, the founder of the company purchased some of the equipment that they were leaving behind and began making tooling,” Doino said.

It didn’t take long for the company to grow, and in 1987, Sotek expanded its reach from the western New York region to the rest of the U.S. Since landing a contract for stamped armature laminations for drive motors in New York City subway cars, Sotek has concentrated its expertise into the manufacture of motors and generators.

“After a short period of time, customers we were making tooling for asked if Sotek could stamp out the parts for them as well, so the founder went out and bought a press and started stamping parts, and it kind of just took off from there,” Doino said.

Wind challenges

Within the wind industry, Sotek is meeting many challenges head on, especially as the wind landscape continues to change, according to Doino.

“Things do move quickly, but as far as the manufacturing processes go, our biggest challenge is just bringing in the manufacturing that’s required to service this industry better,” he said. “It’s more about adapting our own manufacturing footprint to the needs of the wind industry, which tends to be higher volume, larger sizes. So, we are adapting more of our capabilities to meet those larger volumes and sizes than we had worked with in the past. We have adopted robotics where they make sense; we’re constantly upgrading our equipment. We have an excellent supplier network to ensure quality and value in our section of the supply chain, are competitively priced, and can plug right in logistically to our customers’ processes.”

As wind continues to grow, Sotek is making sure it remains heavily involved in future developments.

“We’re positioning ourselves to take advantage of offshore wind as it develops, but in the meantime, we’re also well established with onshore,” Doino said. “We feel that’s really a growth area, ideally suited to us. The push for U.S. manufacturing grows as the market develops, and that’s a direction that we would like our business to grow into. We’re looking to expand into it, and we’re actively seeking additional opportunities that can benefit from a U.S.-made product.”