In any industry, value is often in the eye of the beholder. What works for one company may cost another significantly.

Five years ago, Gearbox Express (GBX) introduced Revolution for the Sle platform because a majority of those turbines were 5 to 8 years old. The theory was these assets would run 20-plus years in a market where power-price increases would be the norm and reliance on the Production Tax Credit (PTC) would phase out.

Fast forward to today and:

- Wind has become very competitive. According to Make Consulting, LCOE (levelized cost of electricity) is expected to fall below $35/MWh within the next five years, outstripping both coal and natural gas.

- Current development boom being fueled by the phase out of the PTC. PPAs (power purchase agreements) are coming in extremely low (sub $20/MWh in many circumstances). This underscores long-term importance of OPEX (operating expenses).

- Given low power prices, independent power producers in a post-PTC environment (after year 10) find it difficult to justify gearbox and or main-bearing replacement.

- Regulated utilities have a rate base used to justify upgrades and increased reliability. They continue to develop and expand wind largely as a long-term hedge against other forms of power generation while the PTC remains nice to have.

- A major “repower” wave is surging through the more than 8-year-old turbine market, exclusively driven by the PTC 80/20 rule. Over 7 GW is expected to undergo some sort of repower activity, qualifying for a second 10 years of PTC providing relief to OPEX pressures.

The total replacement cost for gearboxes needs to be reduced to make wind a more sustainable technology. Yes, power prices are likely to rise, but for wind to be sustainable long term, these costs have to be fundamentally lower while at the same time not sacrificing reliability. Owners of post-PTC turbines not repowering could be lured into chasing a low cost /used gearbox, only to quickly find out the value of its reliability is not there.

What are the options?

Address the in-and-out cost.

- Traditional cranes are expensive. Wind is maturing, and newer technologies are now on the market that are cutting the in-and-out cost in half. Newer, self-hoisting systems can do the job for $75,000 to $100,000 while a traditional crane would cost $125,000 to $175,000. As acceptance in the industry increases, up-front capital cost will reduce, and the in-and-out cost could be as low at $50,000 to $75,000.

- Predictive maintenance is key. It is possible to use condition monitoring as a tool to manage time between failures with de-rating strategies. Turbines can produce power safely until it makes sense to perform the change-out, avoiding costly down time. Furthermore, economies of scale can be realized on the crane mobilization by lumping multiples together.

- Make smart investments. Certain wear debris sensors have become cost effective. They now cost a third to half the price of a traditional full-blown vibration system.

Reduce the cost of the gearbox repair while understanding the reliability tradeoffs.

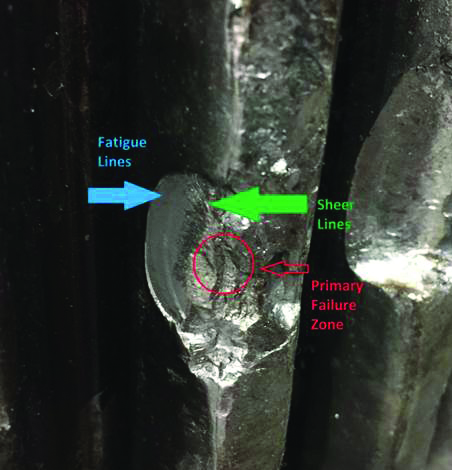

- A full set of replacement gearing represents approximately half the costs of a complete remanufacture. Reusing gears therefore presents a significant opportunity to save cost.

- Used gears can be successfully used if properly inspected to ensure within backlash tolerance and reground to 100 percent clean up (meaning it looks like a new gear). Using gearing as-is or without proper inspection is a recipe for disaster. This is the crux of the material aspect of any warranty: ensure the language is clear, as any gray area implies assumed risk. Make sure suppliers providing a guarantee are transparent with their specifications.

- It’s reasonable to expect a properly reconditioned used gear will run another five to 10 years while a new gear would be expected to last 20 years. For example, if a turbine is 11 years old and the goal is to run beyond 20 years, additional investment must be made up-front so new material can be used. If the goal is only to run another nine years (to year 20), recertified gearing may be a better option. As an example, if the upfront purchase cost of a gearbox with all new gearing was $180,000, a gearbox using recertified used gearing could be $120,000.

- Bearings represent about a quarter to a third of the cost of a complete remanufacture. Paying 20 percent to 30 percent more for upgraded bearings in a few of the positions (planets, high speed, intermediate) will only marginally increase the cost of the gearbox (approximately 5 percent), but substantially improve reliability.

- The remaining cost of the gearbox relates to labor, lube system, seals, and a load test leaving little room for additional savings.

Value is often in the eye of the beholder. As an owner, value takes on different definitions over the life of the turbine. The good news is innovation and industry maturity has brought additional options, and more importantly, transparency, so all risks can be weighed and the true value found.