Soft or loose ground at the site of a new tower can pose challenges to the design of the foundation. Jet grouting can modify this ground into soilcrete; a cemented material significantly stronger than soil. Wind tower foundations bearing on soft or loose ground can experience excessive settlement and bearing capacity failure. If identified prior to construction these soils can be improved or bypassed with a deep foundation system. However, many times poor soils are detected after foundation construction, as the foundation shows excessive deflection. In these cases the existing foundation can be underpinned or existing soils can be improved without removing the existing foundation. Jet grouting is one technique for improving poor soils without removing the existing structure.

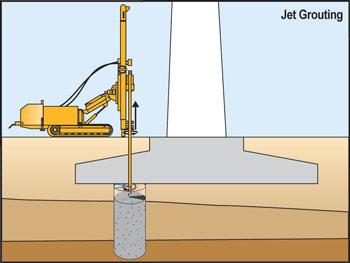

Jet grouting is performed with specialized equipment. Initially a borehole is drilled to the base of the weak soils. Fluids are then pumped through specialized drill rods and nozzles. The high exit velocity from horizontal jets erodes the ground in place and mixes the soil with cementitious grout slurry, producing a soil/cement material referred to as soilcrete. During jetting the drill rod is rotated as it is extracted, producing a column of soilcrete. Upon curing the soilcrete acts more like rock than soil.

Jet grouting is routinely used to support heavy loads, underpin sensitive structures, and mitigate seismic issues. It can be effective in nearly all soils except stiff clays. Although jet grouting can be applied as foundation support for a new tower foundation, the more common application is to remedy conditions beneath an existing tower. An attractive aspect of the technique is that a small diameter corehole through a mat foundation is the only access required to create a large diameter soilcrete column below the foundation.

The treatment geometry depends on the application and ground conditions. Soilcrete column diameters can range from 3 to 15 feet, depending on soil conditions and erosion energy imparted to the soil. For wind tower foundations, the pattern of soilcrete columns is usually circular around the perimeter of the foundation. In this way load is transferred symmetrically to deeper, more-competent ground. If required, uplift loads can be resisted by inserting steel elements (anchors) into the soilcrete and attaching them to the tower foundation. If a tower settles differentially (leans out of tolerance), jet grouting can be used to stabilize the soil causing the settlement. After stabilization, measures can be taken to return the tower to vertical.

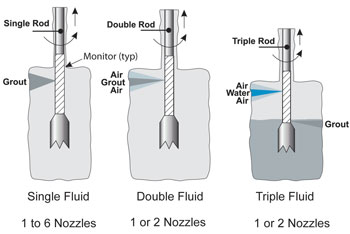

There are three primary methods of jet grouting, all developed in the 1970s: single fluid, double fluid, and triple fluid. Single fluid uses only grout slurry to erode the soil and create the soilcrete. Double fluid uses an air shroud around the jet of grout slurry to increase erosion efficiency. Triple fluid uses an air shroud surrounding a water jet for erosion, while injecting cement slurry to create the soilcrete. The determination of the appropriate system is usually made by the specialty contractor based on the required geometry and ground conditions. Because the systems require consistent control and high energy, specially modified equipment is used. Quality control may include an automated data acquisition system to ensure consistency of the grout and installation properties. Soilcrete samples are typically retrieved by sampling either wet or cured soilcrete. Wet samples are cast into molds and cores are cut into pieces for unconfined compressive strength (UCS) testing. Soilcrete is commonly designed for UCS values ranging between 50 to 750 psi, and with elastic modulus values between 50 to 150 ksi.

As described, jet grouting can provide foundation support and remediation for existing wind tower foundation systems founded on poor soil conditions. This is often an effective, cost-efficient alternative to complete reconstruction of the foundation system.