Wind can’t be made, but what if there was a way to take better advantage of the wind that’s available?

The experts from Biome Renewables say they have discovered a way to do just that with a technology they call the PowerCone™.

A phenomenon called Rotor-Root-Leakage (RRL) at the center of the turbine represents the largest area of aerodynamic loss, according to Ryan Church, founder, CEO, and CTO of Biome Renewables.

“It’s a big problem in wind,” he said. “What’s going on is that you’ve got an area of low pressure, which develops around the hub, because the blade goes from being an airfoil section into this circular root geometry. So, when the turbine is operating, there’s no power being produced there.”

In effect, a low-pressure area is contrasting with the high-pressure region around the outer part of the rotor, causing a pressure differential, according to Church. And that pressure differential causes a suction effect upwind of the rotor.

“The wind is actually diving into this central area,” he said. “Not only is it not doing its job, not only is it not producing power, but it’s actually robbing blades of power that it could be generating.”

Finding inspiration

For his creation, Church, who is a biomimetic designer, found inspiration in an unlikely place: a tiny maple seed.

“I look at the natural world for inspiration, and I derive technology and solutions from that,” he said. “The maple seed is a very efficient structure aerodynamically. What makes it efficient is something called the coning angle, which is the angle the maple seed falls at. And that’s based on a phenomenon we’ve coined Time Dependent Energy Transfer.”

Time Dependent Energy Transfer is basically a principle where the seed takes more time to slow down the wind, thus increasing efficiency while limiting turbulence formation.

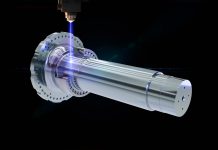

“The maple seed employs Time Dependent Energy Transfer,” Church said. “It’s a phenomenon seen quite widely in the natural world in how nature deals with turbulence. I then harnessed this phenomenon into a geometry, which is the PowerCone. The coning angle of the PowerCone — the way that it swoops backwards — is roughly the same coning angle as a falling maple seed, although it’s slightly different due to scale and flow speed. The point being, once I saw the maple seed, it sort of triggered an ah-ha moment for me in that you could have a three-winged maple seed of sorts and basically fill in the central area of loss in a wind turbine.”

Fits almost all turbines

The PowerCone, which resembles a miniaturized three-bladed turbine, is designed as an enhancement device that can be fitted to 98 percent of all installed turbines around the world. It can be installed on the turbine’s hub in about a day. The result is an increase of AEP by 10 to 13 percent, according to Church, because the PowerCone shifts the entire power curve to the left, meaning an increase in start-up speed.

The simple and elegant technology also equalizes the pressure distribution across the entire rotor disk and reduces the negative impact of wind gusts over time, essentially boosting performance for the entire turbine while reducing loads — something nearly unheard of in the wind industry, according to Church.

“There are a few aerodynamic mechanisms going on,” he said. “It uses something we call a twin-hybrid aerodynamic approach. It smooths out the pressure distribution across the rotor disc. Before, you had an area of low pressure around the hub. When you have the PowerCone on there, now you have an area of high pressure in that region. You smooth out the pressure differential between the outer part of the blade and the center of the turbine. When you do that, you actually even out the velocity differential and decrease the loads on the rotor. So, this is happening at the macroscopic level, in an area far away from the actual device. As the wind is coming into the face of the rotor, it’s no longer diving in toward the middle. Actually, the opposite is happening. It’s getting pushed out a little bit. We actually impact positively the aerodynamics of the entire rotor, not just the central area where it is located, which is one of the keys to understanding the AEP gains that we get.”

In addition to that, the PowerCone also has an effect on the wind that’s directly hitting it, according to Church.

“Where the PowerCone is actually located, the wind is coming along, and it’s hitting our structure, and it’s rubbing along our blades,” he said. “That flow gets directed and concentrated onto the section side of the blade. In doing that, you are eliminating flow separation off the blade by increasing the local boundary layer flow velocity, which leads to a reduction in turbulence and associated vibration. All that vibration would normally be going into the drive train, and now it’s not.”

Pilot test on the horizon

A full-scale pilot test on an operating wind farm of the PowerCone is planned for the first quarter of 2019, which has Biome Renewables working with Arista, Capstone, DNV-GL, and Vestas, according to Church. Two Vestas V-100 turbines will run side by side. One will be used as a baseline, while the other turbine will be fitted with the PowerCone. A ground-based Lidar will be used for atmospheric wind measurements.

“With our tests, what we’re going to be looking at is full turbine loads and impacts on the drive train, including how much vibration we might be reducing,” he said. “We will also be looking at power production and details like nacelle anemometer impact. The PowerCone helps the blade do a better job to produce more lift. The PowerCone itself is providing torque to the system, and it is also channeling that flow onto the blade and allowing the blade to provide more torque.”

That concept is called a twin foil slot technique and is seen in other industries such as sailing, with a main sail and jib, and Formula One.

“In Formula One, in the front of the car, you’ll see these fins channeling the flow around the front part of the tire,” Church said. “That is an aerodynamic technique that is well known. We are doing that on a large scale. The technology is believed to work perfectly well with competitors, too, and may even improve vortex generators and other add-ons that a customer may already have on their turbine, because the PowerCone is simply shunting more air over the VG and enabling it to better do its job.”

Repowering turbines

As turbine repowering becomes an option with aging turbines, Church said the PowerCone is an ideal way to approach increasing an asset’s output.

“This will be a huge boon for the repowering market,” he said. “You can repower a turbine with the PowerCone and have the payback stretched out over a number of years. Obviously, if you have a turbine that’s 15 years old and you’re trying to get the last five years out of it, the economics still work, but it’s not as good as if you have 15 to 20 years to do the same thing. This is a question of being the right technology at the right time. There’s a surge occurring in the market, and we’re fortunate to be in the right place at the right time.”

Perfect for low wind

Another benefit of the PowerCone is its ability to be implemented in areas where wind power wasn’t feasible before, according to Church.

“You can now install wind turbines in areas where you couldn’t before, and the technology has more of an impact in lower average wind speeds,” he said. “Class 3 is low, and that’s 7 1/2 meters per second average. They have a new class called ultra low, which is 6 meters per second average. And soon I’m sure they may have a fifth class, which is ultra-ultra low, which could be 5 meters per second average. With the PowerCone technology, it works in all wind classes, but it works better in low wind because more of the wind bins are stacking up in the ramp-up portion of the power curve.”

More than 50,000 person-hours over the past few years have gone into the development of the PowerCone, and that hard work is already paying off, according to Church.

“It is selling itself,” he said. “What we know about the technology is that it decreases the cut-in speed of the turbine. And you also hit rated power earlier. So, you shift the whole power curve over to the left, and you get huge gains in AEP because most of the wind distribution is happening in the low wind bins. When you do that, you really unlock the full potential of wind power. You unlock new markets for wind power. You enable bids for new wind power to be cheaper than they ever were before when you bid in a PowerCone into a project. There are a lot of different business models and plans we’re going after. The O&M market is a huge market for us.”

Along with using the PowerCone for wind, Church said Biome Renewables is also involved in renewable energy as a whole, including adapting the PowerCone technology for tidal energy.

The PowerCone has come a long way since Church built a wind tunnel in his living room to test his theory born from a falling maple seed.

“The PowerCone is the fundamental flagship technology that we’re coming to market with,” he said. “But there’s also quite a few technologies that we’re working on that will complement the PowerCone.”

More info: biome-renewables.com

What’s a typical day like for you at Campbell Scientific?

What’s a typical day like for you at Campbell Scientific?