One ice detector solution for OEMs and operators is to borrow off-the-shelf technology from the global telecommunications industry.

Smart phones are manufactured in extremely high volumes around the world. This has forced the price of optical lasers and LEDs down to just pennies apiece. Plastic optical fibers are likewise made in vast quantities, with prices just pennies a foot.

With today’s tele-components being reliable, common, and cheap, they should make excellent building blocks for wind-turbine ice sensors — and they do. (Figure 1)

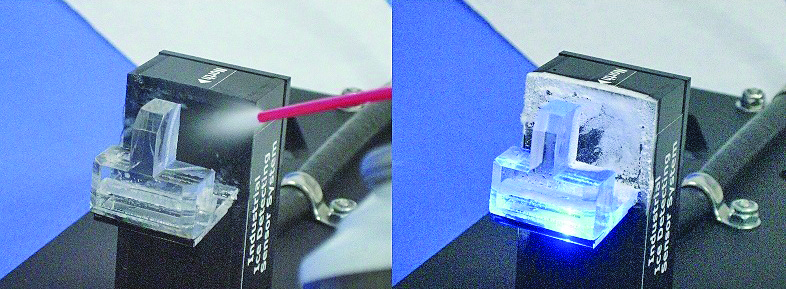

Modern ice detectors are entirely optical. In the modern ice sensor, a tele-component light source and receiver monitor the opacity and refractive index of whatever substance is in contact with the probe. Other than ice itself, little else would have intimate contact with an ice sensor high atop a wind-turbine nacelle. Liquid water simply runs off by gravity, but ice sticks to the optical surfaces for sensing.

Since they have no moving parts, modern ice sensors and housings can be scaled very small — about the size of a thumb — and potted solid against the elements. This is an improvement over hermetic sensor housings, because solid sensors are robust against moisture and vibration as well.

Modern ice detectors work as a combined optical spectrometer and optical switch. A change in opacity registers as rime ice; a change in refractive index registers as clear ice.

The wavelength of the sensor’s excitation signal is invisible to the human eye, so as not to cause a distraction. At the same time, its clear sensor probe is useful to display a blue ice-indicating LED, helpful to turbine technicians working aloft (Figure 2).

Modern ice sensors eliminate many of the problems with legacy ice sensors, being generally lower in cost, lighter in weight, and smaller in size. Simple relay contacts eliminate the need for interpretation and send a “go/no-go” “ice/no-ice” indicating status to the host control system. This simplifies the interface while reducing software complexity and cost.

Optical ice sensors (Figure 3) are lightweight and easy to carry aloft and install. They run on any convenient DC power source 8-30 volts and need only 2 watts to look for ice. Unlike legacy sensors, modern ice sensors detect and report the absolute presence of ice on a wind turbine, do not artificially melt the sensed ice away, and do not require additional power supplies and power budgets.

Bearing heat signatures

Following the path of legacy ice sensors, modern ice sensors were also recently developed for aircraft. Smaller, lighter, more sensitive, and cost effective, they are easily adapted to wind turbines and autonomous drones for wind farms.

Other, wider applications for modern ice sensors include virtually any place with a need to sense the formation of hazardous ice and take corrective action in a timely manner, such as heat pumps, radio and TV broadcast towers, HVAC cooling towers, hydrogen car engines, traffic signals, vehicular bridges and overpasses, remote power lines, water-level sensors in oil and gas installations, and more.

Ice sensor prices are eroding because overall demand and production volumes are increasing.

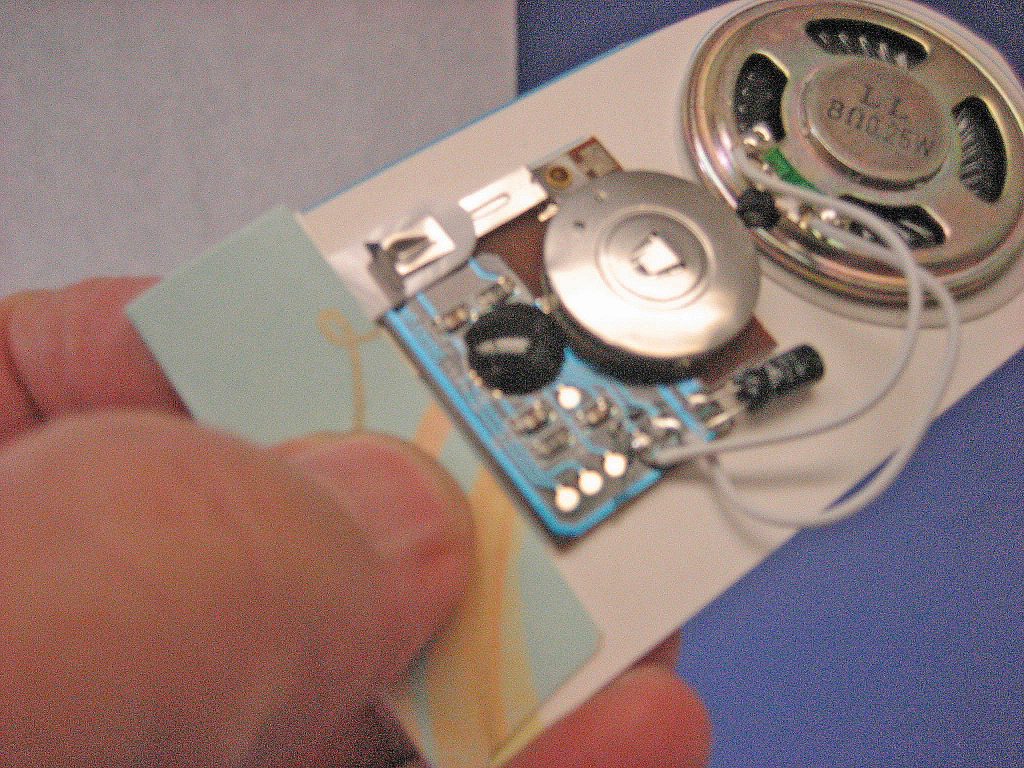

They are increasing because modern ice sensors enjoy wider applications in high-volume drones and refrigerator defrost controls. The ultimate manufacturing volume for optical ice sensors is projected to approach that of musical greeting cards (Figure 4) in multi-million-unit volumes, with prices expected in the sub-$10 range.

Tested in the the world’s largest icing wind tunnel at NASA Glenn (Figure 5), modern optical ice sensors comply with SAE Aerospace Standard AS 5498 ¶ 5.2.1.1.1 for FAA-mandated ice protection of autonomous BVLOS (beyond visual line of sight) drones.

FAA compliance is a major breakthrough for wind-farm drones. Modern ice sensors invite drones to use the darkness of night to autonomously monitor the IR heat signatures of turbine bearings and other equipment for signs of impending failure.

If the sensors flag anomalous high temperatures, observe nighttime intruders, the movement of wildlife, flocks of birds, or colonies of bats, the sound of an ultrasonic horn will safely shoo them away, autonomously, without damage to the blades or requiring the services of an FAA-licensed drone pilot. The pilot is built right into the operating system, along with a virtual GPS-defined “fence,” delineating airspace beyond which the drone is disabled, and cannot fly.

Dynamic blade inspection

Modern fifth generation ice sensors are capable of detecting the formation of ice films only molecules thick.

Upon sensing an initial film of ice molecules, the modern ice sensor of a BVLOS wind-farm drone (Figure 6) would help protect the drone against ice by sending an interrupt to the host operating system and prompt it to briefly reverse the fan blades. The top surfaces of a drone’s fan blades are more susceptible to ice molecules than the bottom surfaces because air above the blades is colder due to lower pressure (lift), while the air below the blades is warmer due to higher pressure.

Warmer air briefly swept over the top of the fan blades overcomes newly-formed ice molecules’ latent heat of fusion, changes their state back into liquid water, and retards formation of ice on the drone. (The latent heat of fusion of water is 80 calories/gram.)

This proven fan-reversing ice removal technique is common on HVAC cooling towers for large data centers, apartment buildings, campus buildings, hospitals, etc., which also use modern optical ice sensors for ice protection.

Daytime and nighttime detection

Protected against ice during daylight hours on a fixed schedule under SCADA control, autonomous wind-farm drones would take off and inspect a specific circuit of turbines.

Rather than stop the turbines and lose valuable production time, each dedicated wind-farm drone would take advantage of its inherent agility and inspect turbine blades in a spiral on the fly, without stopping the turbine. Record high resolution blade images and other key features, fly autonomously to the next turbine like a honey bee collecting nectar in a field of flowers. It then would return to its garage for a robotic battery swap-out or charge.

Protected against ice during nighttime hours, autonomous wind-farm drones would also serve as night watchmen, using the cover of darkness to monitor the heat signature of turbine bearings and other equipment for signs of impending failure.

In the unlikely event of fire or other anomaly, SCADA would immediately dispatch its BVLOS drone for video monitoring and situational awareness before technicians and fire apparatus could arrive.

In addition to end-of-warranty inspections and preventive maintenance, inherent advantages of ice-protected autonomous drones include safety, objectivity, uniformity, accuracy, low cost, and real time dissemination of critical data.

Ice on wind turbines may be hazardous to people and things, but the use of abundant, low-cost optical components to make ice sensors provides simple, inexpensive solutions for turbines and dedicated on-site drones.

SIDEBAR

A dozen other ways to detect ice

Daytime visual: Visual observation of ice on turbine members during daytime hours, with field glasses or naked eye.

Nighttime visual: Strategic illumination of turbine members with either white or red light. A red light shining upward through an acrylic panel is inconspicuous at night, but when ice forms on it, the red light diffuses and provides a visual form of ice alert.

Mechanical obstruction: A scraper rotating on an exposed surface. As ice accretes on the surface, the torque required to rotate the scraper increases. At some preset torque, a signal is generated, setting off an ice alert.

Differential pressure: A hollow probe senses air pressure through small orifices on its upwind face. As ice blocks the orifices, a pressure differential signal is created setting off an ice alert.

Latent heat: A periodic current pulse is sent through a resistance element to heat an exposed probe. If ice has accreted on the probe, the temperature increase will temporarily dwell at 0°C and set off an ice alert.

Vibration: Ice on a vibrating reed slows its resonant frequency, which is detected and used to energize a heater, which melts the ice and pulses pneumatic boots on an aircraft wing. The frequency of pulses sets off an ice alert.

Microwave: A microwave transducer consisting of a resonant surface waveguide is embedded into an exposed surface on which ice accretes. The ice acts as part of the waveguide; changes its phase, and sets off an ice alert.

Electromagnetic beam interruption: An EM source is placed on one side of a flattened tube and directed at a sensor on the other side of the tube. As ice accretes on the tube, the signal is blocked and sets off an ice alert.

Ultrasonic: Sound waves are reflected off an ice/air interface and sensed by a transducer. When ice is present, the reflected waves are perturbed, sensed, and used to set off an ice alert.

Capacitance: A total impedance ice detector uses the capacitance of a surface-mounted electrical circuit to determine the presence and thickness of ice and sets off an ice alert.

Optically occluding: An optical source directs light at an optical receiver. An accreting surface close to the beam accretes the ice, senses ice blocking the path of the beam, and sets off an ice alert.

Optically refractive: An optical source sets off an ice alert by using un-collimated light to monitor the opacity and optical index-of-refraction of whatever substance is on the probe, either air or ice.