Site and operator safety is an ever-increasing concern and fundamental consideration for all companies, in all industries, globally.

Within any sector where operators and technicians are working on controlled bolting applications, the risk of pinched fingers and dropped-object-related injuries is exceptionally high. These risks must be recognized and dealt with appropriately to enable preventative injury strategies to be implemented.

Raising awareness internally and supplying equipment designed with the operator’s safety in mind is key, and it illustrates the risks involved when correct safety precautions aren’t followed. How to counteract them can help to increase awareness by using real life examples everyone can relate to.

Hands Free Bolting Ltd, an e-commerce safety product provider, has recognized the requirement for safe and simple accessories to form part of companies’ preventative injury strategies.

By using simple, innovative, easy-to-use safety accessories, operators can carry out hands-free bolting works, therefore eliminating the pinch risk and other related injuries.

%%0118-HFB%%

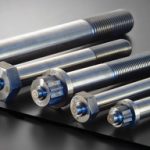

Accessories such as the No-Flog® 2, Back-Up Nut, and Safety Valve form part of Hands Free Bolting’s product range.

The No-Flog 2 is a safe alternative to typical flogging spanners and can be used to stop back nuts turning during the make up or break out of bolted flanges and joints. When used alongside the Back-Up Nut, the accessories provide a completely secure solution. The Back-Up Nut allows bolting tools to be held in place at any angle during operation, allowing the operator’s hands to be free while the tool is in use.

Also available is the Safety Valve, an isolation device fitted in-line between the pump and tool. Designed to provide the operator with complete control of tool operation, the safety valve ensures the operator has no risk of accidental tool activation.

“Each product within the Hands Free Bolting product range has been designed to work together seamlessly to offer complete safety for operators,” said Lynsey Gibbs, Hands Free Bolting’s business manager. “With the risk of both hand and dropped-object related injuries increasing, we want to provide our customers with simple preventative solutions to promote safe working. We are committed to a product development schedule to introduce further products to continually support industry in its safety planning and processes.”

Source: Hands Free Bolting Ltd

For more information, go to www.handsfreebolting.com.