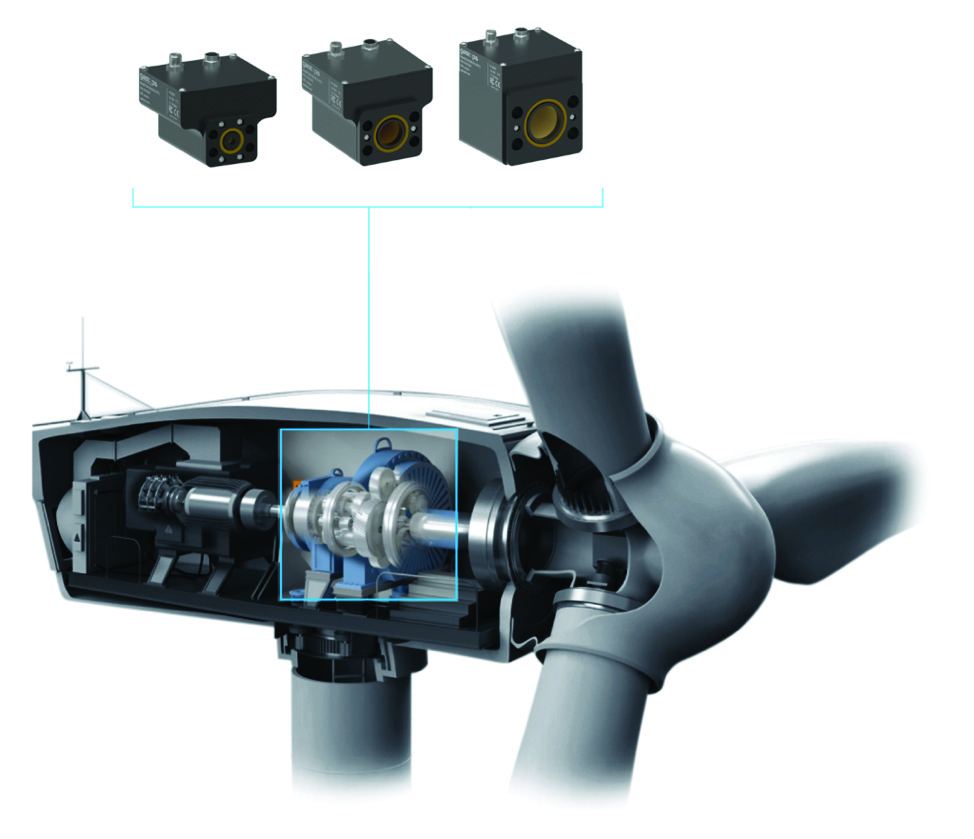

Gastops, a leader in critical component condition intelligence, announced the first volume shipments of the MetalSCAN MS3500 online condition monitoring sensors to a major wind-turbine manufacturer for their next generation platform, the fourth manufacturer to adopt MetalSCAN technology as standard equipment.

The MS3500 series provides the wind-energy industry with online access to real-time condition monitoring data, which enables the earliest reliable detection of component damage available on the market today.

“MetalSCAN MS3500 replaces the MS3000 series to further enhance the value proposition for the world’s leading wind turbine manufacturers by helping wind-energy operators reduce costs and risk,” said Cedric Ouellet, director of energy and industrial at Gastops. “With the MS3500 series, we have introduced key new functionality and connectivity capabilities to support Industrial Internet of Things (IIoT) implementations at a lower price point, all while maintaining the performance and reliability for which Gastops is recognized.”

The MetalSCAN MS3500 series delivers real-time detection of 100 percent of ferrous and non-ferrous metal particles generated during component damage. The sensors generate continuous component condition data to provide advance warning of abnormal component wear or debris accumulation exceeding defined limits. This intelligence gives wind-energy operators the power to plan maintenance in advance, predict the remaining useful life of critical equipment, and avoid secondary damage that leads to costly component replacements.

“Our MetalSCAN technology was developed to meet the demanding standards of the aviation and defense markets,” said Shaun Horning, president and CEO of Gastops. “As with our previous generation of sensors, the MS3500 series packages that advanced technology into a market leading solution that is now more valuable than ever to both wind turbine manufacturers and operators. We are very excited to be bringing our latest innovations to the renewable energy industry.”

Gastops provides intelligent condition monitoring solutions used in aerospace, defense, energy, and industrial applications to optimize the availability, performance, and safety of critical assets, offering online monitoring sensors, at-line analysis, complex modeling and simulation, laboratory testing, engineering, design, and MRO services that predict performance to enable proactive operating decisions. Gastops has been providing insights into the condition of critical equipment since 1979.

More info www.gastops.com