Airborne Motorworks, Inc., (AMW) an innovator in sustainable technology, recently announced the success of software developer Maya HTT’s independent analysis of its patented wind-turbine design. This technology marks a leap forward in the quest for high efficiency, clean and localized wind-power generation.

AMW’s Wind Turbine offers a host of features that promises to reshape the emerging renewable energy landscape:

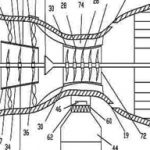

With an innovative aerodynamic design and advanced materials, the AMW Wind Turbine captures more wind energy through its airfoil designs, circumferential shroud, and two-stage contra-rotating rotors to generate electricity with remarkable efficiency.

Using low friction technology, AMW has prioritized noise and vibration reduction in its wind turbine. By using noise-reduction technology, the wind turbine produces minimal noise disturbance in the 40-50 dB range at a distance of 25 meters making it an ideal choice for virtually any environment, e.g., high density urban and suburban environments as well as rural applications. The sleek and modern design of the AMW Wind Turbine allows for easy integration into various landscapes. Its compact and low-profile features ensure minimal impact on the environment while delivering maximum energy output.

While AMW is focused on the fast-growing microgrid market, the product confirmation analysis by Maya HTT suggests a broad spectrum of turbine sizes and potential applications giving way to future expansion of this technology into additional markets.

Built to withstand harsh weather and corrosive conditions, the AMW Wind Turbine is engineered with durable materials such as carbon fiber, titanium, and stainless steel. Its low friction design ensures longevity, consistent performance, and its low maintenance costs are enabled by the absence of a gearbox and traditional power generator module often found in legacy designed wind turbines. Also, the AMW design is air washed thereby eliminating the need for oil-based lubricant and coolant systems that hold 400 to 700 gallons of oil in large wind turbines and require scheduled replacement.

The AMW Wind Turbine is equipped with advanced smart grid digital AI technology in accordance with the International Energy Agency’s (IEA) Smart Grid initiative. This global initiative is aimed at introducing sustainable economic development, energy security and interdependence-enabling seamless integration into existing energy infrastructures, thus improving grid stability at a local level, and expanding the collective of renewable energy sources.

AMW is committed to sustainability throughout the product lifecycle. The AMW Wind Turbine is manufactured using eco-friendly recyclable materials and processes, reducing its carbon footprint.

“Our goal is to contribute to high efficiency electric power generation, and greater power generation diversity through microgrids to achieve a cleaner more sustainable and reliable energy future; with the AMW Wind Turbine now validated, we believe we have taken a significant step toward achieving that goal,” said AMW executive chairman and CEO Hugh McElroy.

“This groundbreaking technology is expected to play a vital role in increasing the availability of primary and backup power generation in the 100 KW to 500 KW range with the ability to extend power output above 1 MW by synchronizing a bank of our units to power key industrial infrastructure, large buildings, universities, government facilities, and residential communities.

The AMW microgrid wind turbines’ close proximity to the energy user can significantly reduce wasteful transmission line loss, while its highly efficient design minimizes global dependence on fossil fuels and produces virtually no greenhouse gases.”

The AMW Wind Turbine is soon to enter the final stages of its durability testing and is expected to be ready for production manufacturing by the end of 2024.

More info www.airbornemotorworks.com