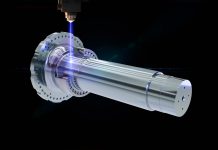

Carl Zeiss Industrial Measuring Technology (IMT) has introduced the new ACCURA®. By systematically implementing customer requests, it has developed a multi-sensor capable measuring system that permits fast, economical, precise, and flexible measurements.

Measure dynamically, precisely and safely: Thanks to the steel and aluminum components, the new ACCURA measuring machine bridge is extremely rigid and thin. The CARAT® coating (Coated Ageing Resistant Aluminum Technology) on the aluminum parts ensures long-term stability of guideway behavior. The low weight of the moving parts improves the dynamics. This allows the ACCURA to achieve a maximum vectorial travel speed of 800 millimeters per second—50 percent faster than its predecessor—in the Performance Package configuration. This speed demands increased protection measures. Therefore, the Performance Package contains a special safety system: laser scanners monitor the protection zone around the measuring machine during the high-speed mode. If the safety system registers movement within this zone, the machine speed is automatically lowered within one second. Once the disruption passes, ACCURA reaccelerates to the original measuring speed. The enhanced air bearings also play a key role in the dynamic behavior of the bridge. Thanks to the thinner air gap, they are more rigid and require less compressed air than previous air bearings.

Foam insulating technology enables higher temperature independence: The ACCURA bridge features a new, high-performance insulation—foam insulating technology. At minimal thickness, the housing covers ensure temperature resistance. This guarantees the required precision even on the shop floor.

Freely selectable temperature range (20-26°C): Measuring machines must be operated at constant temperatures to avoid temperature-dependent deformations. A fixed measuring lab temperature of 20°C is standard. The new ACCURA can be operated with the same precision at other temperatures between 20 and 26°C. The measuring lab temperature can therefore be set appropriately and you save air conditioning costs.

Tailored to customer demands: As with a versatile modular system, customers can configure the ACCURA to fit their requirements. Based on their current tasks, they select the ideal configuration, i.e. sensors. Special software, such as GEAR® PRO for gears and HOLOS® NT for freeform surface measurements, is integrated along with CALYPSO®, the standard CAD-based measuring software from Carl Zeiss. Subsequent modifications can be made very easily. The ACCURA is available at a very economical price for this performance class. If requirements change, different sensors and software can be easily added. Whether cut, shaped, or molded parts, plastic or steel—all options of coordinate measuring technology are available. The ACCURA also permits the integration of MASS® technology from Carl Zeiss. Combined with an RDS articulating probe holder, MASS permits the fast, measuring program-guided change between contact sensors and the ViScan® and LineScan optical sensors during a CNC run. The contact measuring sensors of the VAST® family and the DT single-point sensor can also be used in various configurations.

The new ACCURA is currently available in four sizes, each of which offers a large measuring range—even with an integrated stylus changer. For more information contact Chris Grow at (763) 744-2400 or cgrow@zeiss.com. Go online to www.zeiss.com.