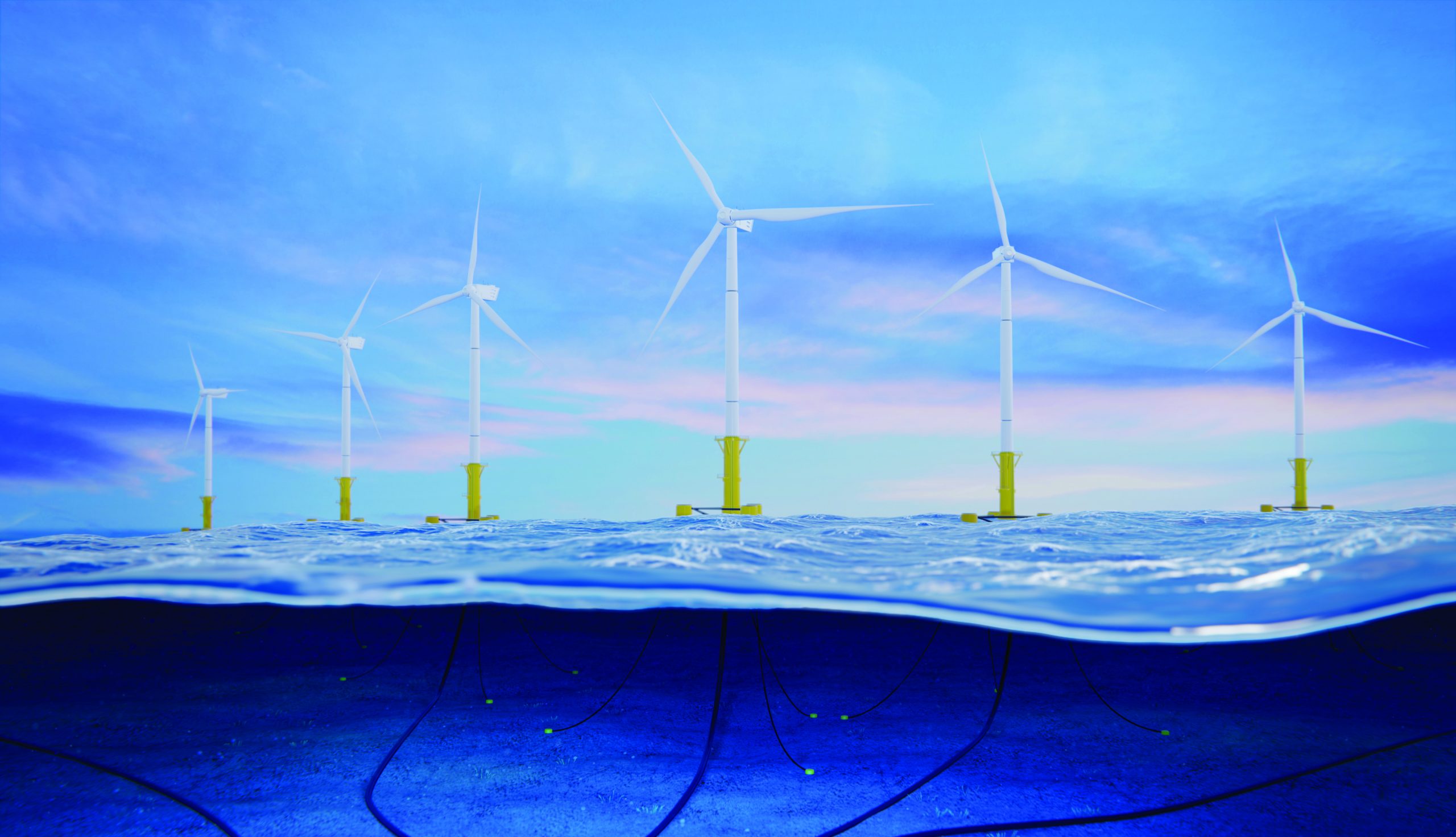

More than 40 percent of the U.S. population lives near the coast, and the demand for clean sustainable energy is skyrocketing. Renewable energy is important to many Americans but so is a pristine waterfront view. The clear solution is harnessing deep-water, far offshore wind, allowing for consistent 24/7 energy production with turbines so far out at sea they are barely visible to the naked eye, thereby preserving critical nearshore views.

Power companies serving coastal communities are looking to work with offshore wind developers, and one of the most efficient, lower-cost energy potentials is predicted to come from far offshore wind. According to Bloomberg New Energy Finance, the offshore wind market will grow 19 percent annually over the next eight years, reaching a cumulative capacity of 71 GW in 2025. According to the American Clean Power Association, more than 60 percent of this offshore wind energy will serve the U.S. coastal population. The time has come for the aesthetics and cost of offshore wind energy to be addressed.

Fixed Bottom WTGs

In 2016, the first fixed bottom, offshore wind farm in the U.S was installed off the coast of Rhode Island. Since then, an additional 13 offshore wind leases have been awarded on the East Coast and one on the West Coast. The East Coast projects will be 6-MW to 14-MW fixed bottom wind turbine generators (WTG).

Fixed bottom WTG are installed in two stages: first the installation of the fixed bottom structure, then later, the deployment of the WTG using a jack-up installation vessel. This vessel can lift itself off the seabed with four massive leg structures, providing the on-board crane the stability and capacity out of the water to assemble the WTG. These jack-up vessels are limited to 200 feet of depth, which prohibits their installation in deep-water.

Direct-Drive WTGs

The U.S. offshore wind industry is committed to the development and deployment of larger, taller, stronger turbines with 14-MW to 20-MW direct-drive wind turbine generators (DD/WTG) to be deployed far out to sea (30 miles), in deep water, where the wind consistently blows at hundreds of feet above sea level. These new, larger DD/WTG will have the ability to produce more power from a single turbine all on a single floating platform. They will offer greater efficiency in power generation than height restricted land-based platforms and include other substantial benefits that include:

- A 722-foot diameter rotor with smart blades is covering a wider area of wind.

- The outer tip of the blades on some large DD/WTG can be as much as 853 feet above mean sea level to reach stronger and more consistent winds.

- The far offshore, deep-water deployment location is far away from critical near-shore fishing grounds and bird migratory routes.

- The distant location means any noise produced is well out of ear shot of coastal residents.

- When viewed from the shore, the slow turning blades of these new turbines will appear to be the size of a silver dollar. The curvature of the Earth will place a large portion of the turbines’ mast below the horizon, while the white or gray blades and mast will all but disappear in most atmospheric conditions.

DD/WTG will have a gross capacity factor of 63 percent. These numbers are starting to close in on the most efficient geothermal energy sites in the U.S. operating at 74 percent.

Floating Foundation Design

The large new 14-MW to 20-MW DD/WTG will be the most powerful offshore generators to date. Their large size requires a floating foundation design with a strong resistance to overturning and heave motion of the high seas. European offshore wind floating foundation developers have more than 15 systems in varying stages of development but replicating them for use in U.S projects is problematic.

The U.S. has only two in the same stages: the semi-submersible and the U.S. spar buoy. The semi-submersible floating foundation is the result of a 10-year study now being prototyped full scale by the University of Maine. The efforts are being funded by a joint venture of Diamond Offshore Wind and RWE Renewables. The U.S spar buoy floating foundation, also 10 years in development, is in an advanced stage of technical readiness by a West Coast company, AMF Concepts. Both floating foundation systems are being scaled-up to support 14-MW to 20-MW DD/WTG and now must rethink their construction and deployment.

The University of Maine’s 15-MW offshore DD/WTG on a floating semi-submersible foundation has a tow-out width of 335 feet, a height of 885 feet, and a depth of 65 feet. However, the deepest harbor in the U.S. is 52 feet. The mooring width off the quay cannot exceed more than 30 percent of the harbor’s water ways. The average bridge, if encountered, has a 220-foot clearance. Finding solutions to overcome these restrictions will be challenging and require further study.

The U.S. spar buoy construction and deployment has evolved from a system originally designed to be built vertically on an ocean-going deck barge, then in a dry dock, then on land, with the final design using a vertical slip down system at a sea-anchored construction site outside the harbor.

Floating Spar Buoy

Scaling the U.S spar buoy to accommodate large DD/WTG has resulted in a floating spar buoy with an 80-foot outside dimension and a length of 625 feet. The construction design includes an integrated method of deploying the DD/WTG without the use of a crane ship and the associated exorbitant costs. Avoiding dependence on a crane ship is incredibly important for the growth of far offshore wind technology in the U.S. since the only crane ship design for offshore wind is still being tested in Europe. A crane ship from Europe cannot be used in the U.S since the Jones Act requires the ship has to be built and crewed in the U.S.

Europe has been building offshore wind for 25 years primarily because it ran out of space to build on land. It currently has deployed more than 5,000 WTGs at sea. In the U.S., we have seven. This makes for a sad commentary for a country that prides itself on being a technological leader in so many other industries. Europe has commercialized wind, and it is selling it to America, China, Japan, etc. All of the major wind developers over the last 10 years have set up companies in the U.S. such as Equinor AS, a Norwegian oil giant; Edpr Offshore out of Spain; Aker from Norway, Ideol and Principal Power, both from France; and Orsted, a Danish company.

Most of the offshore wind developers in the U.S. are partnering with these companies to serve this U.S. market for offshore wind. For the foreseeable future, all of the WTG and foundations being erected in the U.S. will be coming from Europe, and 98 percent of their experiences is in fixed bottom construction. This provides a unique opportunity for the U.S. to take the lead in the design, construction, and development of deep water far offshore wind energy.

Massive Offshore Energy Potential

The National Renewable Energy Laboratory estimates there is a potential for capturing 4,333 GW of clean energy off the U.S. coasts, with the majority of it in far offshore deep water. The Offshore Energy Market predicts the future could include 10 clusters of 50-MW DD/WTGs covering an area of 50 square miles on each coast. This idea is based on expert projections from the International Energy Agency that far offshore, deep water wind is set to become a critical pathway for the global energy transition.

Our carbon-neutral future requires clean renewable energy, and the time is now for the U.S. to develop the new generation of systems necessary to harness the sustained winds found far out at sea. The U.S. is already developing a high-strength marine concrete with a new binder and rebar for the sustainable construction of post tension turbine towers for 14-MW to 20-MW DD/WTG. This alone could be a huge new industry.

Far offshore wind farms will be a major contributor to green energy with no impact to critical land mass. With investment in the design and implementation of the floating foundations necessary to successfully deploy DD/WTG in deep water far offshore locations, the United States could lead the way toward commercializing the far offshore wind industry for the whole world.