Wind-turbine blades are coated with one or more protective coatings to help them withstand the effects of erosion from rain, sand, hail, and dirt. In most cases, the full structure of the laminated reinforced blade is coated first with a standard two-component protective coating. The leading edge of the blade tip receives another special protective layer to protect against the extra risk of rain erosion. New cartridge-based dispensing technology improves the quality and reliability of this leading-edge protection layer, while making it safer and more efficient for those conducting repairs using rope access.

Erosion is directly related to the speed that rain droplets, hail stones, and other airborne particles, (also known as rain erosion) hit the blade. Blade tips are subject to the fastest speeds because when it rains, as the blade rotates up, the falling speed of the rain adds to the blade’s tip speed, hitting the blade at a higher rate. This increased speed leads to faster rate of erosion, an effect that can be likened to sandblasting.

European wind-turbine blade standards expect blades to last 20-25 years — in reality they last from 10-15 years, and even that lifespan is impossible without a coating or some sort of leading-edge protection. In fact, an uncoated blade (also known as a blunt blade) will not last a year. Erosion effects can be seen in as little as a few weeks if there is a strong rain. Protective coatings are absolutely necessary to protect the blade’s leading edge.

Wind turbines are regularly inspected using a variety of techniques. Inspection, using drones or other methods, identifies the blades that need to be repaired and determines the type of repair necessary.

If full service of the blade is necessary, technicians remove the entire blade and repair it on the ground.

Many smaller repairs require simply renewing three to four meters of the leading-edge protection. These repairs can be quite time-consuming. Rope access is the standard method for smaller repairs. For larger repairs, a platform is maneuvered with a rope from the top of the tower.

Several different methods for coating the leading edge are used, including multi-layer coatings and specialized tapes applied over the standard coating.

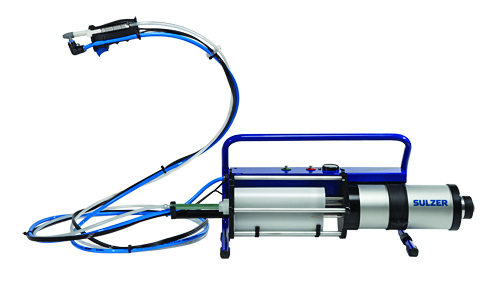

New cartridge-based systems for applying protective coating to wind-turbine blade leading edges improve repair processes by replacing time consuming and inaccurate manual mixing and dosing. Using cartridges can be a huge advantage for workers performing rope repairs prevalent in minor repairs of turbine blades.

Workers either have to premix before going on the rope or mix at the point of installation — a difficult task while hanging by a rope 60 to 80 meters off the ground. These systems also increase the quality of the repairs, because, in general, 90 percent of coating failures (apart from insufficient surface preparation) are due to inaccurate mixing or dosing, a problem eliminated by using a cartridge.

For example, one system that provides extra protection and abrasion/erosion resistance on highly stressed areas like leading edges of wind turbine rotor blades is the Mankiewicz ALEXIT® BladeRep LEP 10DM. The two-component, solvent-free polyurethane product is usually applied using the cartridge-based Sulzer MIXPAC™ MixCoat™ Flex Hose Brush Protective Coating Dispensing System.

Sulzer cartridge-based dispensing systems are also used in the RELEST® Wind LEP ETU system, as well as in products made by several manufacturers of leading-edge coatings.

Cartridge-based dispensing technologies reduce labor, waste, and disposal costs, while adding reliability and improving safety. Use of new applicator-friendly cartridge-based dispensing technologies reduces manual mixing and dosing, improving repair quality, and making tricky rope work easier. For blade repairs that require application of leading-edge protective coatings, these systems are an excellent option.

More info www.sulzer.com